ACME thread Go Nogo gauge from manufacture TruThread

ACME Thread Gauges are important tools in the field of metalworking and mechanical engineering. They are used to measure and check ACME-type threads, which play an important role in drive mechanisms on machine tools where rapid movement is required, or in screw jacks where uniform load distribution is required.

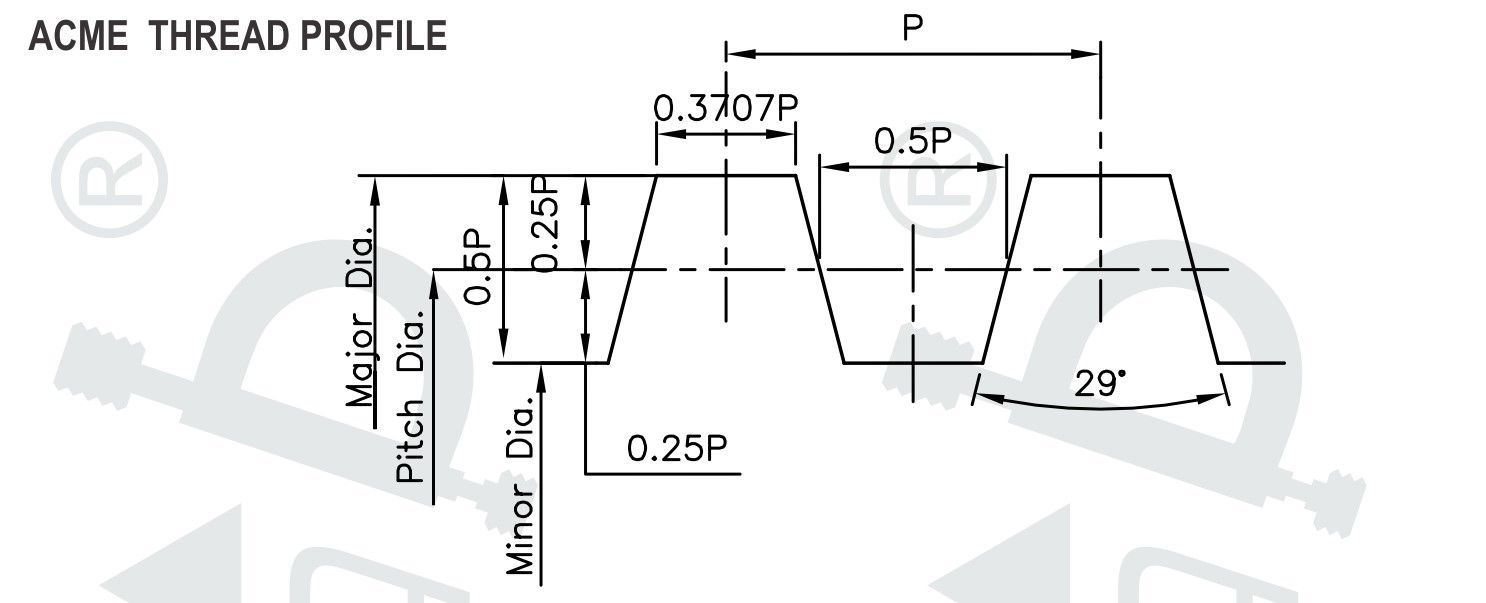

ACME thread gauges are very similar to trapezoidal threads, but have a 29° inclusion angle, which makes them different from other thread types. The main feature of ACME Threads is their use in the imperial inch system of measurement, while trapezoidal threads are subject to the metric system.

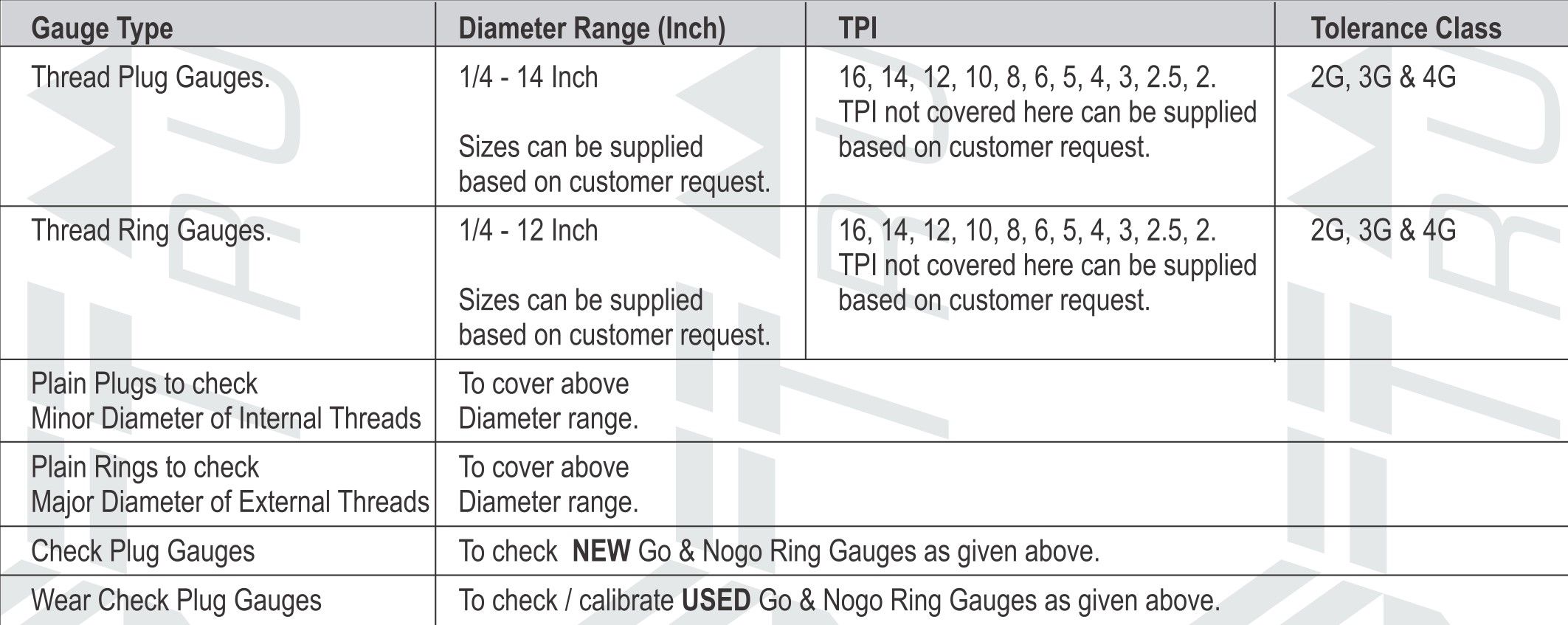

Technical characteristics of ACME thread gauges

Specifications: American specification: ASME B1.5 - 1997, B.S. Specification: B.S. 1104 - 1957

TruThread manufacturer range

Tolerance class: G - is the most commonly used Tolerance Class 3G - class is used for general purpose assemblies while classes above 3 are progressively close tolerance classes like 4G, 5G ect. Classes below 3 are having coarse tolerance and are suitable for loose fit. Example 2G class.

Centralizing ACME Threads

Centralizing Acme have limited clearance at the major diameter of screw & nut. The limited clearance enables a bearing at the diameter to maintain alignment of the thread axis preventing the wedging on the flanks & part sugging. Five classes are used 2C, 3C, 4C, 5C, 6C.

ACME thread use and features

These thread gauges are essential to ensure the quality and accuracy of drive mechanisms in metalworking and mechanical engineering. They allow you to check and adjust the threads on screws and nuts used in machine tools and jacks to ensure reliable and safe operation of machines and equipment.

With the help of ACME thread gauges, any defects or inconsistencies in the thread can be detected, which helps to avoid accidents and facilitates the repair and maintenance of machines. Thus, these thread gauges play an important role in ensuring the quality and efficiency of metalworking and the production of high-quality products.

STUB ACME thread rings and plugs from TruThread

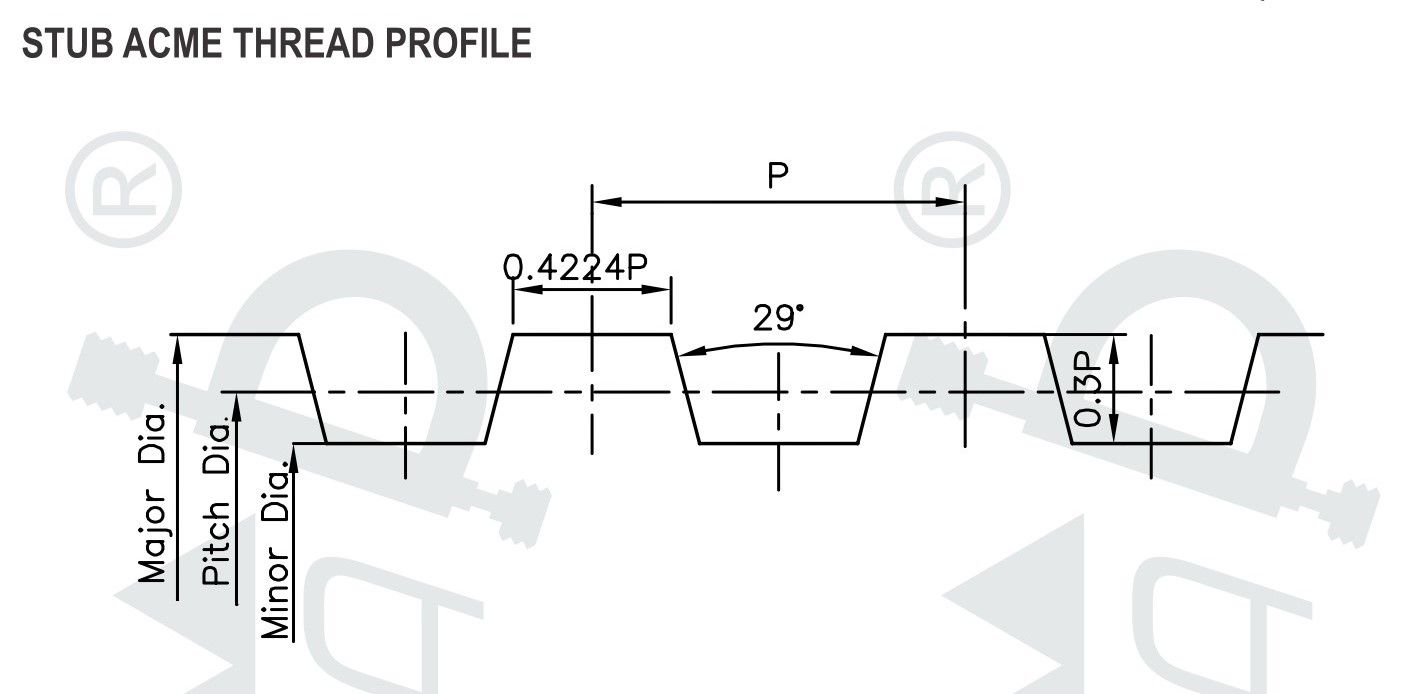

STUB ACME thread gauges are a special type of tool used in critical areas where coarse thread pitch and thin-walled parts are required. This thread is a variation of the regular ACME, but it has a lower profile and a smaller inclusion angle. STUB ACME threads are known for their reliability and ability to provide stability under high pressure and load conditions.

One of the main features of STUB ACME gauges is that they are often used in thin-walled parts and pipes where a coarse thread pitch is required, but ACME threads cannot be used due to size limitations. It is especially often used in the oil and gas industry to create pipes and equipment that must withstand high pressure and difficult operating conditions.

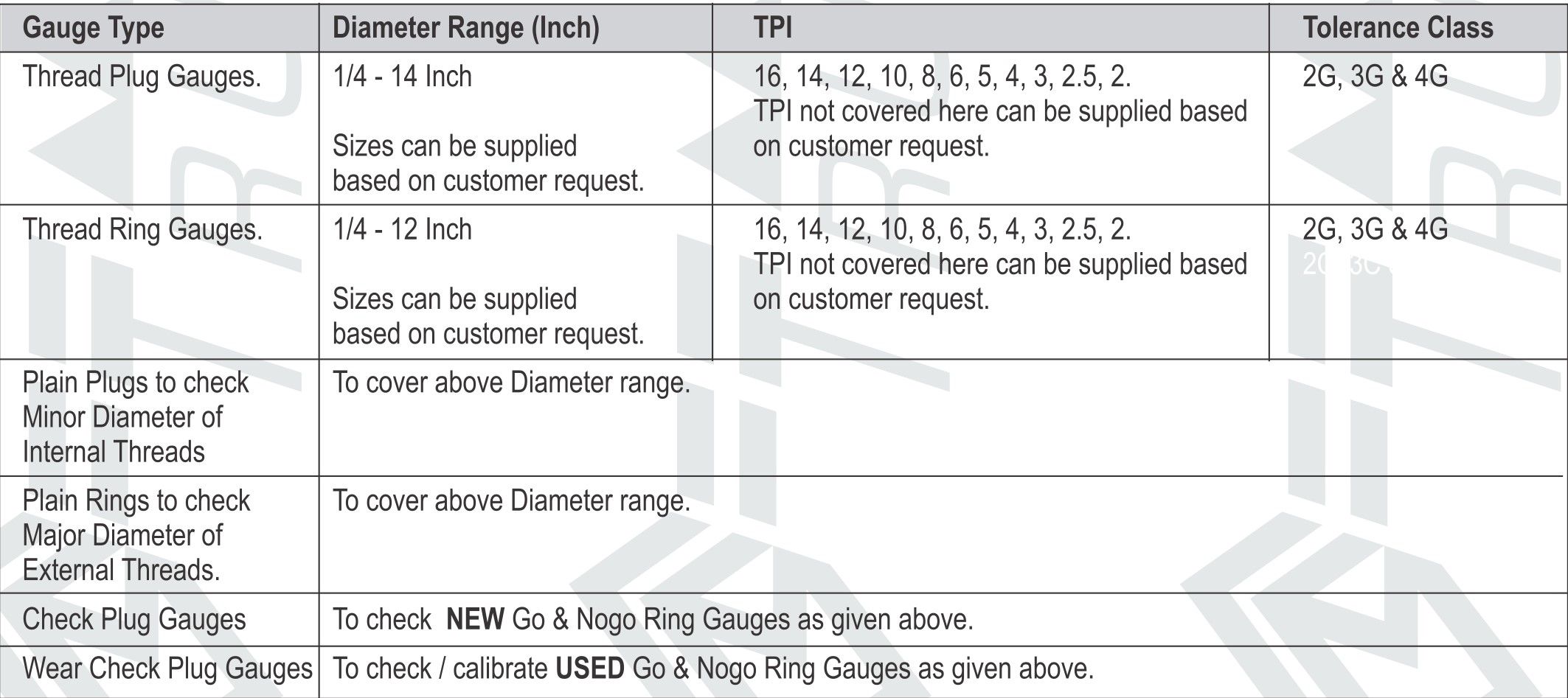

Technical characteristics of STUB ACME thread gauges

Specifications: ANSI/ASME B1.8 - 1988

TruThread Manufacturing Range

Gauges for modified STUB ACME threads - STUBACME M1 & STUBACME M2 are covered in our manufacturing range.

Gauges for modified STUB ACME threads - STUBACME M1 & STUBACME M2 are covered in our manufacturing range.

Centralization of STUB ACME Threads

Centralizing Acme have limited clearance at the major diameter of screw & nut. The limited clearance enables a bearing at the diameter to maintain alignment of the thread axis preventing the wedging on the flanks & part sugging. Five classes are used 2C, 3C, 4C, 5C, 6C.

Use of STUB ACME thread rings and STUB ACME thread plugs

STUB ACME thread connections are used in a large number of engineering, aviation and automotive applications where precise and reliable transmission of motion is required. Their design allows to ensure stability and efficiency of measuring systems and driving mechanisms in various industries.

STUB ACME thread rings and thread plugs are essential components in mechanical systems. These elements play an important role in ensuring the correct operation and reliability of connections and mechanisms.

STUB ACME thread ring gauges:

Checking Internal Threads: These gauges are used to check internal STUB ACME threads, such as in internal holes, nuts or other connections. They help determine whether the size and shape of the thread meets the given standards and specifications.

Determination of thread roughness and condition: STUB ACME ring thread gauges are also used to detect possible defects, such as thread unevenness or scratches, which can affect the quality and reliability of the connection.

Ensuring compliance with standards: They allow you to check whether STUB ACME threads meet certain standards and requirements, which is important to ensure the interchangeability and quality of parts and connections.

STUB ACME Thread Plug Gauges:

Checking External Threads: Plug gauges are used to check STUB ACME external threads, such as on shafts, pipes or other external parts. They help determine the accuracy of threading parameters and dimensions.

Determining thread depth: Plug gauges can be used to determine thread depth and control the depth of thread protrusions, which is important for proper assembly and connection of parts.

Control of thread diameter: They allow you to check the diameter of the thread and detect any deviations from the specified values.

The use of STUB ACME ring and plug thread gauges can ensure high quality and accuracy of manufactured parts and connections, reduce the possibility of damage to mechanisms and ensure interchangeability of parts in different systems and industries.

STUB ACME gauges play an important role in measuring systems, mechanical engineering and equipment for the oil and gas industry, providing reliability and efficiency under conditions of heavy loads and high pressure.