Gauges B.S. Conduit - reliable connections of electrical pipe fittings

Gauge B.S. Conduit is used for fittings (connecting elements) of electrical conduits used for conducting electrical wires and cables. This thread is used in wiring systems to create reliable and safe connections between pipes, couplings and other components.

These specialized measuring tools are designed to check and calibrate threads on steel pipes and are used in electrical wire and conduit systems in the construction industry and electrical installation work. Gauges B.S. Conduit plays an important role in ensuring the accuracy and reliability of the conduit system and helps to avoid the costs and time associated with incorrect threading and joining of pipes.

B.S. Conduit Thread Gauges are manufactured from high quality materials and have calibration accuracy that meets B.S. (British Standard). This allows them to reliably check the thread on the pipes and ensure its compliance with the requirements of the standard.

Gauges B.S. Conduit: technical characteristics and application features

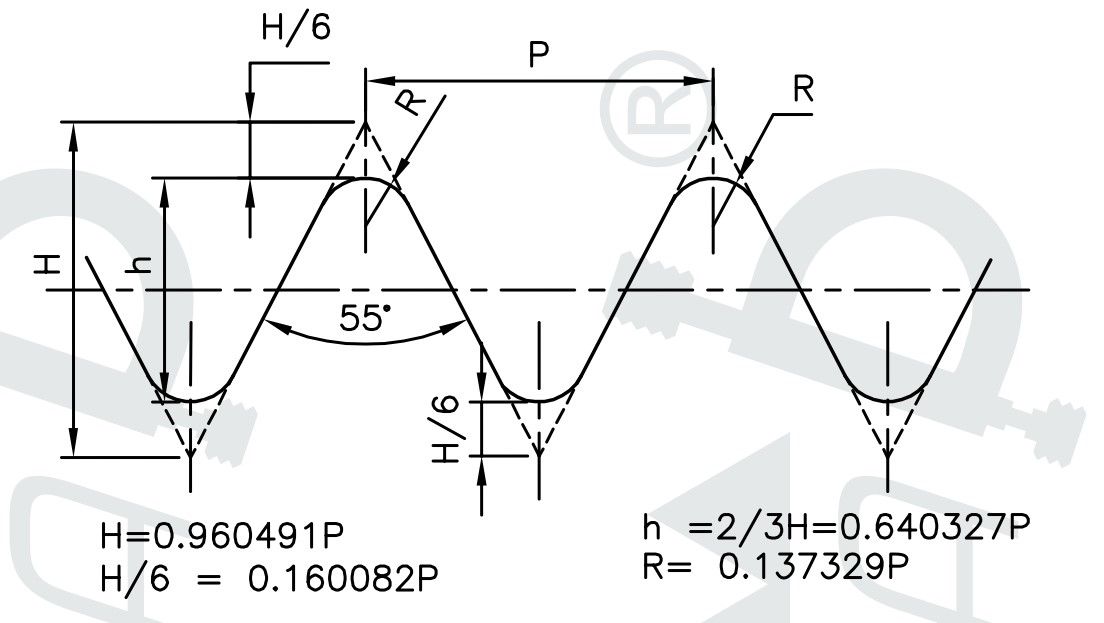

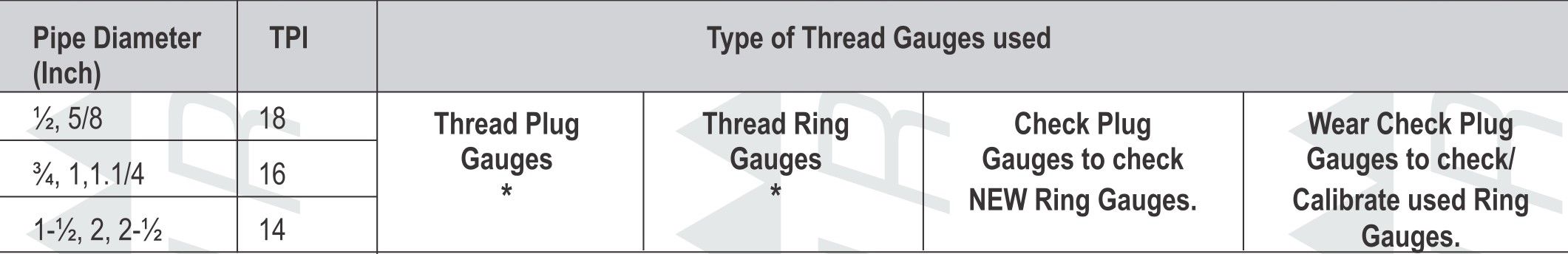

Specifications: Standard Dimensions & Gauging Practice: B.S. 31 - 1940

Tolerance: class B

Specifications recommend thread GO and plain Nogo

Tolerance: class B

Specifications recommend thread GO and plain Nogo

An important feature of the B.S. Conduit gauges is its use in the British Standard measurement system. This allows you to standardize and ensure compliance with the dimensions and specifications of fittings and conduits used in electrical installation works.

The application of thread B.S. Conduit gauges are necessary to ensure the safety, reliability and compliance of electrical wiring. It allows you to correctly and safely connect the components of the conduit, creating an efficient system for laying electrical wires and ensuring the transmission of current to the intended destination.

The important advantages of using B.S. Conduit thread gauges are:

- Ensuring standard and correct threads on pipes.

- Reducing the risk of leaks and malfunctions in pipeline systems.

- Effective use of resources and prevention of material waste due to incorrect carving.

- Increasing the safety and reliability of electrical installation works.

All of these factors make B.S. Conduit Thread Gauges are essential tools for electrical and construction professionals, helping to ensure the quality and reliability of electrical systems and conduit.

British Standard Cycle Threads - gauges for the bicycle industry

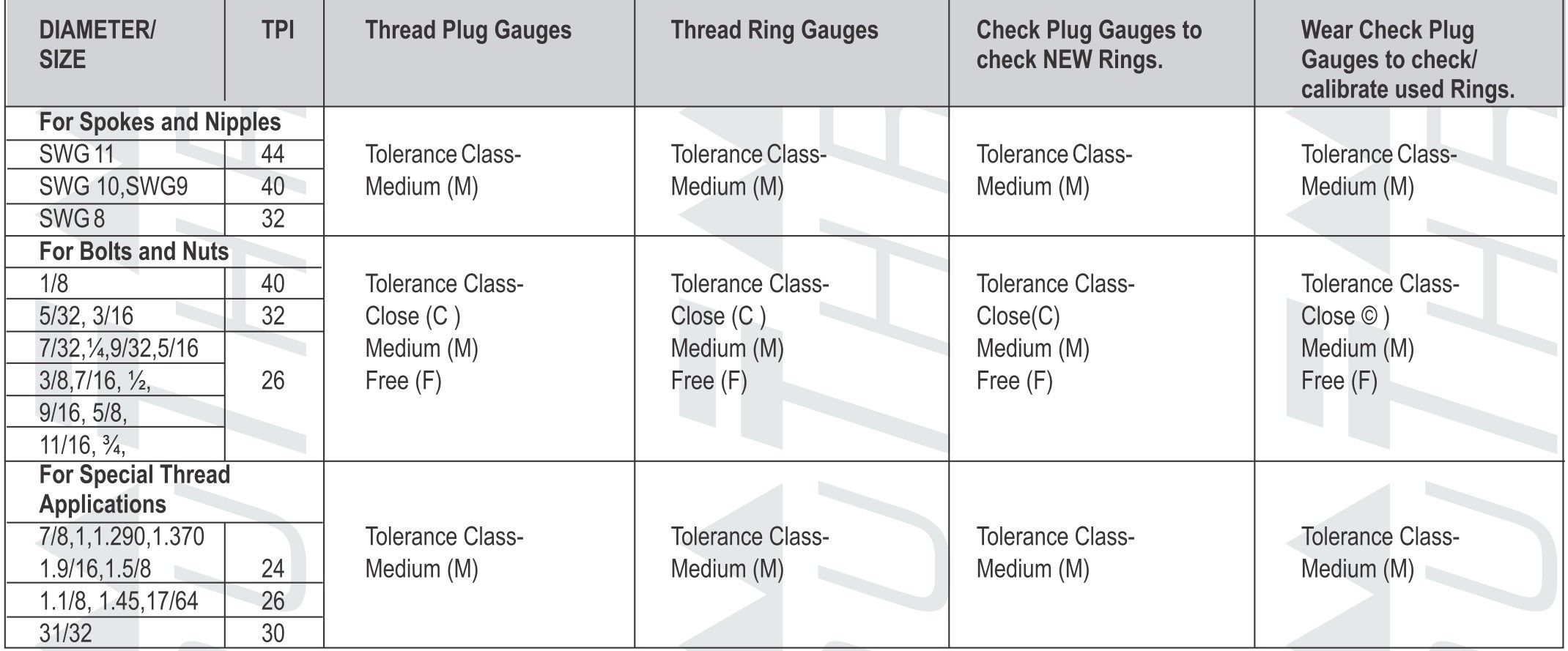

B.S Cycle Threads are used for spokes, nipple nuts, bolts in the cycle industry and in the manufacture of motorcycles. The British Standard Cycle threading standard is the British standard for imperial threading. The small pitch of the thread allows the use of high torque values and is resistant to vibrations.

In the production of bicycles and motor vehicles, the most important thing is precision and reliability. Small parts such as spokes, nipples, bolts and nuts play an important role in creating a quality and reliable bicycle. Precisely machined threads on these parts provide the necessary strength and fixation that is crucial to the safety and efficiency of every ride.

British Standard Cycle Gauges: specifications and description

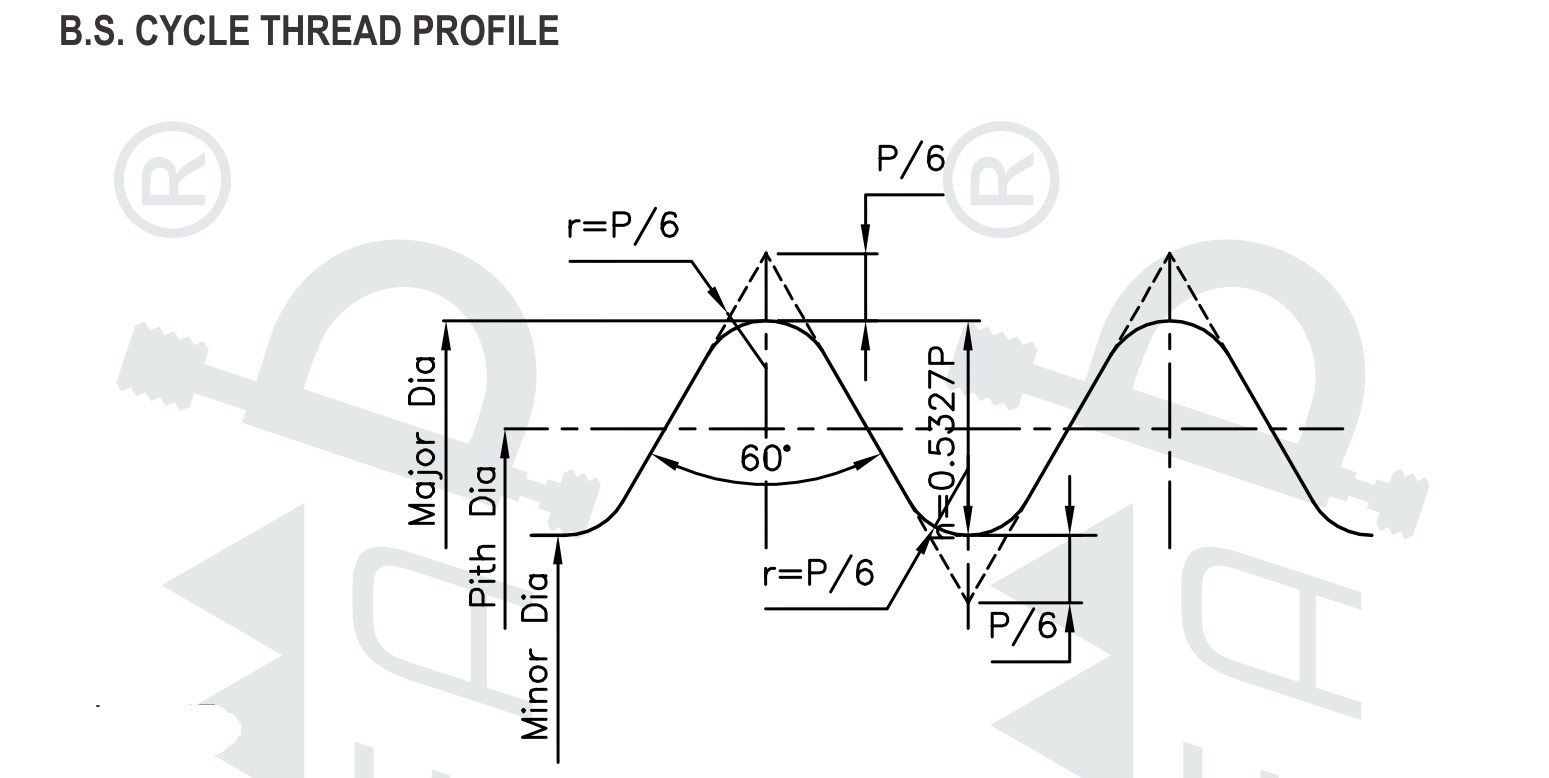

Specifications: Basic Dimensions: B.S. 811 - 1950. Gauging Practice: B.S. 919 Part II - 2007.

The differences between this threading standard, the British Standard Cycle (BSC or BSCy), from other important British threading standards such as the British Standard Whitworth and the British Standard Fine are its bevel angle, which is 60 degrees, as opposed to the usual 55 degrees. All sizes from 1⁄4" and up use 26 threads per inch (tpi), resulting in commonality with ISO 1mm threads, which are 25.4 per inch and also have a 60 degree lead angle. This characteristic gives the BSC standard high interchangeability and allows it to be used in various dimensions and configurations, providing convenience and efficiency in installation and use.

This standard arises from the specific needs of the bicycle and motorcycle industries, where every detail plays a key role in creating reliable and safe vehicles. British Standard BSC is distinguished by its precision and provides the necessary characteristics to ensure strength, wear resistance and optimal performance of every connection where this thread is used. Thus, the BSC standard is recognized in its industry and continues to ensure quality and stability in bicycle and motorcycle manufacturing.

Quality and reliability of TruThread's B.S Cycle gauges

B.S Cycle gauges guarantee high accuracy and standard thread parameters, which allows to achieve optimal compatibility between different components of two-wheeled transport.

The importance of proper threading in the bicycle industry cannot be understated. They affect the stability, durability and safety of each bicycle. Therefore, the selection of appropriate threading gauges is a key step in the production of high-quality bicycles.

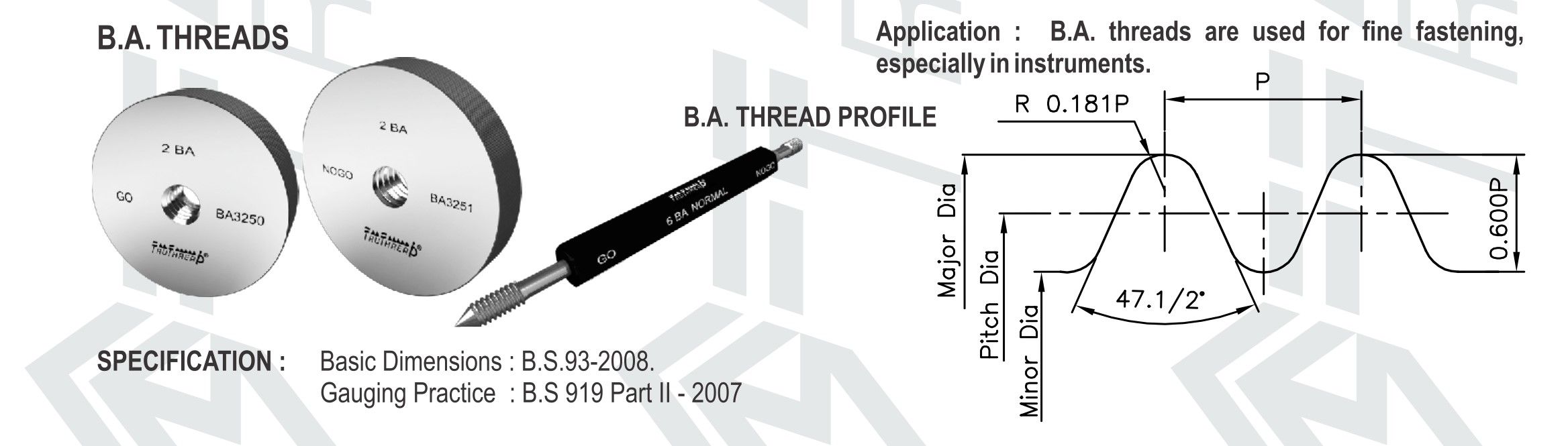

British Association threads - gauges for screws of small sizes

B.A. Threads (British Association threads) is a threading system developed by British specialists for small screws, especially important for precise fastening, in particular in appliances and tools. The angle of the thread is 47-1/2 degrees. Although this system has metric dimensions, it is not traditionally metric: screw diameters are determined by a factor proportional to the power of the logarithm to the base 10 of the thread pitch in millimeters.

B.A. Threads widely used on British cars, especially on small screws under 1/4 inch. For screws B.A. special sizes of wrenches are used. The name "British Association" was named after the British Association for the Advancement of Science, and the standard for this system was developed in 1884, and later, in 1903, it was officially agreed and published.

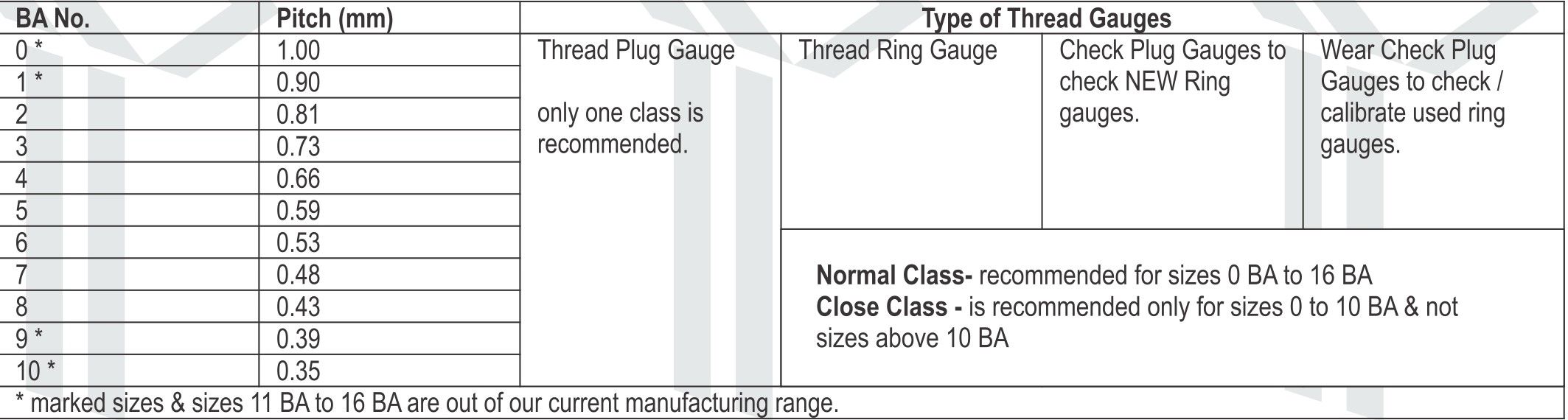

Thread gauges B.A: description and characteristics

Specifications: Standard Sizes: B.S. 93 - 2008. Measurement practice: B.S. 919 Part II - 2007.

Screws are designated as 2BA, 4BA, 6BA, and 8BA, with a larger number indicating a smaller screw size. Larger and odd numbers are rarely used except in equipment manufactured before the 1970s, particularly for telephone exchanges in the UK, where odd numbered screws were used to reduce theft.

Dimensions of B.A. threads are defined by British Standard BS and include sizes from 0 B.A. up to 16 B.A. In actual terms, size 0BA has a diameter of 6 mm and a pitch of 1 mm. Other sizes of the BA series are determined in geometric proportion with common factors of 0.9 and 1.2. For example, a 4BA screw size has a pitch of 0.65 mm and a diameter of 3.62 mm. Although size 0BA has the same diameter and pitch as M6 coarse, the threads are different shapes and incompatible.

Application of thread gauges B.A

Thread gauges B.A. are still widely used in some industries, particularly precision equipment such as moving coil gauges and watches. Gauges B.A. were also used in the aviation industry, especially in the British aircraft industry. B.A. threads are still used in railway signaling systems, primarily for connecting electrical equipment and cables. In the field of threading model engineering, B.A. are widely used to represent large-scale fasteners, due to their smaller nut head sizes.