Buttress Thread Gauges - for buttresses, transmission devices and connecting parts

Buttress thread gauges are special tools used to check the correct size and shape of threads on internal and external threads of the buttress type threads.

Buttress Thread is a special type of thread that is widely used in various fields of engineering and mechanics. It is mainly used for transmission devices, and can also be used to connect parts. One of the main features of buttress carving is its asymmetric shape, which resembles reinforcement or support.

Technical characteristics of Buttress Thread Gauges

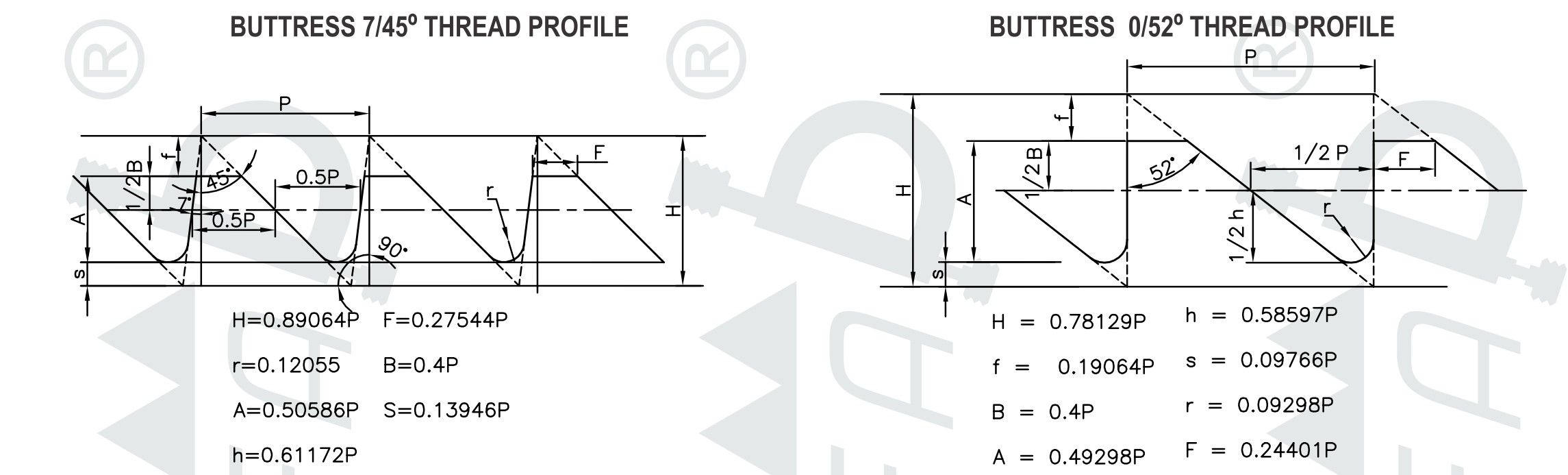

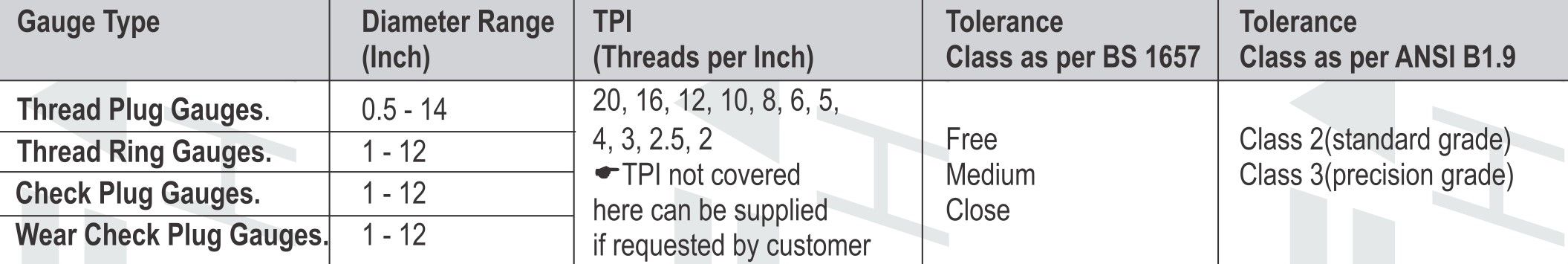

Specifications: B.S.1657 - 1950 used for 7°/45° and 0°/52° thread profile & ANSI B 1.9-1973 for 7°/45° thread profile

TruThread manufacturer range

The basic type of American buttress thread includes different sizes to meet the requirements of different applications. Technical characteristics of Buttress Thread gauges demonstrate their ability to withstand axial loads directed in one direction, making them ideal for applications where large forces act in only one direction.

These characteristics confirm the high quality and reliability of booters gauges and emphasize their ability to withstand loads in one direction, which is important primarily for structures that require reliability and strength when transmitting large forces.

Peculiarities of using Buttress Thread Gauges

The shape of the buttress allows you to withstand the load in one direction, while combining the high efficiency and strength of the thread with the ease of threading and adjustment of the thread. This makes the buttress thread an ideal choice for situations where reliable fixation and transmission of large loads in one direction is required.

The main application of these gauges is the quality control of buttress carving on parts or products. They are used to check whether the parameters of the thread meet the specified specifications and standards. Buttress thread gauges allow you to determine whether the diameter, step, angle of inclination and other parameters of the thread on the part meet the requirements.

Typically, these gauges are used in metalworking and mechanical engineering, where buttress threads can be important to ensure reliable connections and support large loads in one direction. Examples include threaded parts for artillery systems, aircraft propellers, hydraulic columns, and many other applications where precision and reliability of threading is required.

Metric Saw Tooth Gauges for checking sawtooth threads

Saw Tooth Gauges have a number of important applications similar to those of Buttress Thread Gauges. The main similarity is that both types of gauges are used to measure and control threading, but Metric Buttress or Saw Tooth Gauges specialize in threading in the metric system, distinguished by the fact that their dimensions and measurement parameters correspond to the metric system, not the imperial system of measurements.

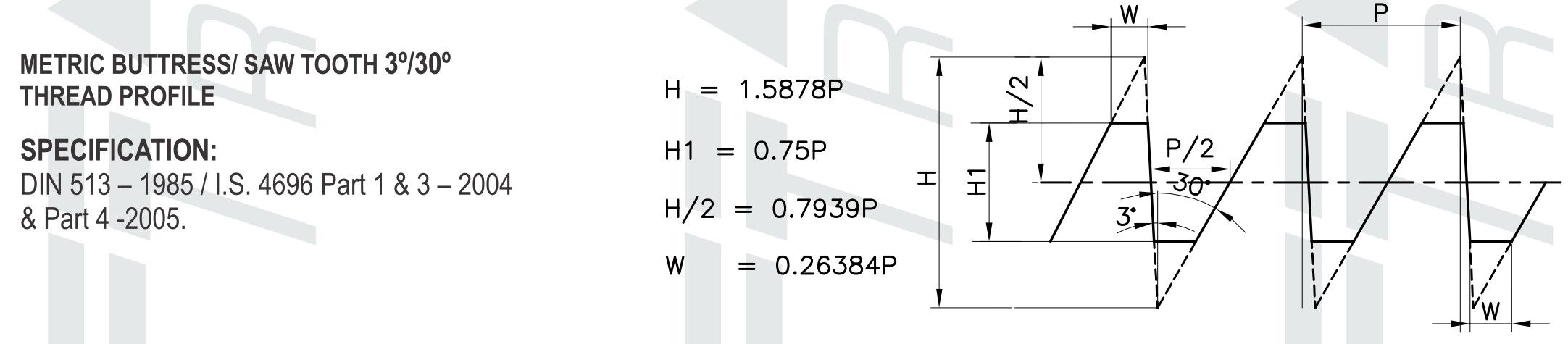

In particular, Metric Buttress or Saw Tooth Gauges are designed to measure and control threads with a Metric Buttress or Saw Tooth profile with a specification of 3°/30° Thread Profile (3 degrees of inclination and 30 degrees of deviation from the vertical). This requires accurate data to measure threading parameters such as depth, pitch and tooth shape.

Technical characteristics of gauges for saw-tooth threads

Specification: B.S.1657 - 1950 used for 7°/45° and 0°/52° thread profile & ABSI B 1.9-1973 for 7°/45° thread profile

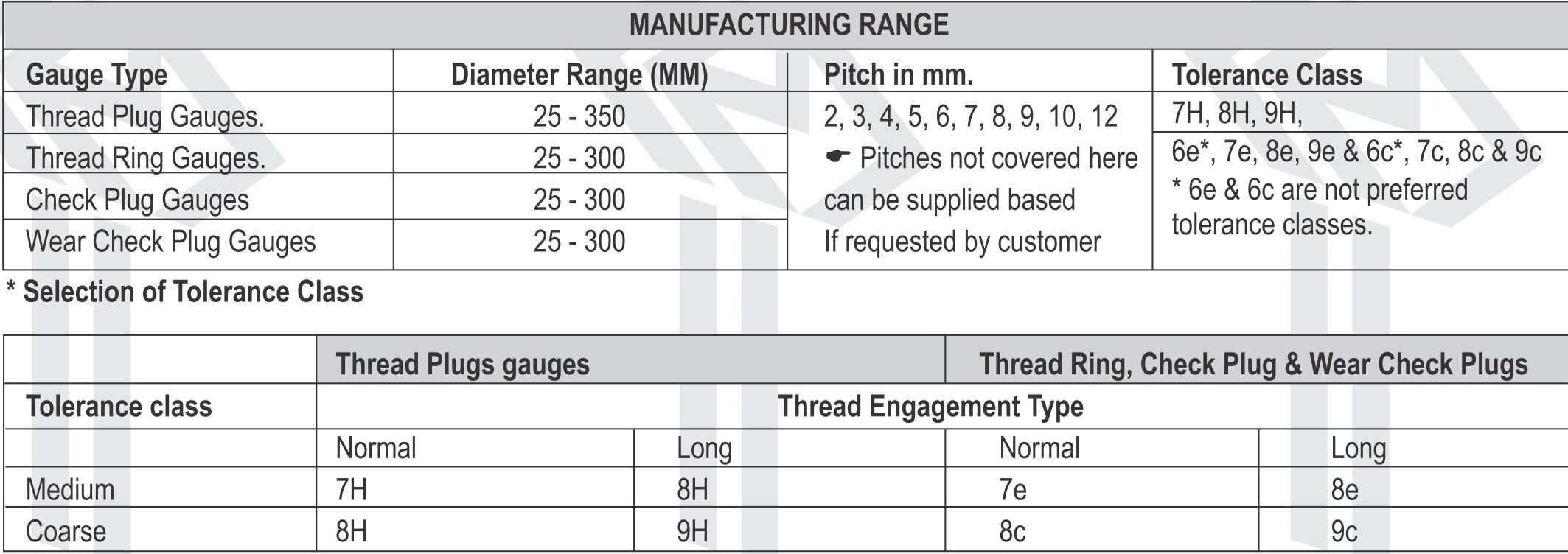

Manufacturing range

Saw Tooth Gauges can have different configurations, depending on the type of tool and the requirements of the particular application. They usually have internal and external threads to measure the depth and shape of the teeth. Professionals use these gauges to check, adjust and maintain cutters and saws in optimal working order.

Peculiarities of using Buttress gauges in the metric system

The applications of Metric Buttress or Saw Tooth Gauges can be varied, including the production of cutters, saws, cutting tools and other similar tools in various industries. They help ensure cutting quality and accuracy, as well as safety and productivity in gear cutting processes in the metric system.

Properly designed and calibrated Metric Buttress or Saw Tooth Gauges can help avoid tool defects and breakages that can lead to workplace accidents.

TruThread Europe is your trusted supplier of high quality metric Saw Tooth Gauges. Our gauges are accompanied by certificates from the manufacturer, guaranteeing their correct calibration and the use of the best materials.

We are also happy to manufacture gauges to your individual dimensions and requirements. Email us to order custom made gauges and our team will be happy to help you get the tool you need for your production and quality control needs. You can count on the highest quality and reliability from TruThread Europe.