M KEG Taper Thread Gauges for thread inspection in the oil industry

M KEG Taper Gauges stand out as special tools designed to measure and control a thread connection in a tapered form. They are usually used in industries where it is important to provide a reliable connection point for grease and oil, and when it is necessary to achieve a tightness that self-tapping connections cannot provide, even with the help of parallel threaded connections together with sealing washers.

It is important to understand that these special gauges play an important role in technical systems where control of the taper thread is necessary. They are used to test and ensure the accuracy and reliability of connections used in the oil and hydro industry, where reliability and leak prevention are critical. M KEG thread taper gauges allow you to make sure that thread parameters meet the requirements of standards and specifications, thereby guaranteeing the safety and efficiency of equipment and lubrication systems.

Technical characteristics of oil conical gauges M KEG

Specification: Basic Dimensions: DIN 158 Part 1 - 1997/IS8788 -2002, Gauging Practice: DIN 158 Part 2 - 1997.

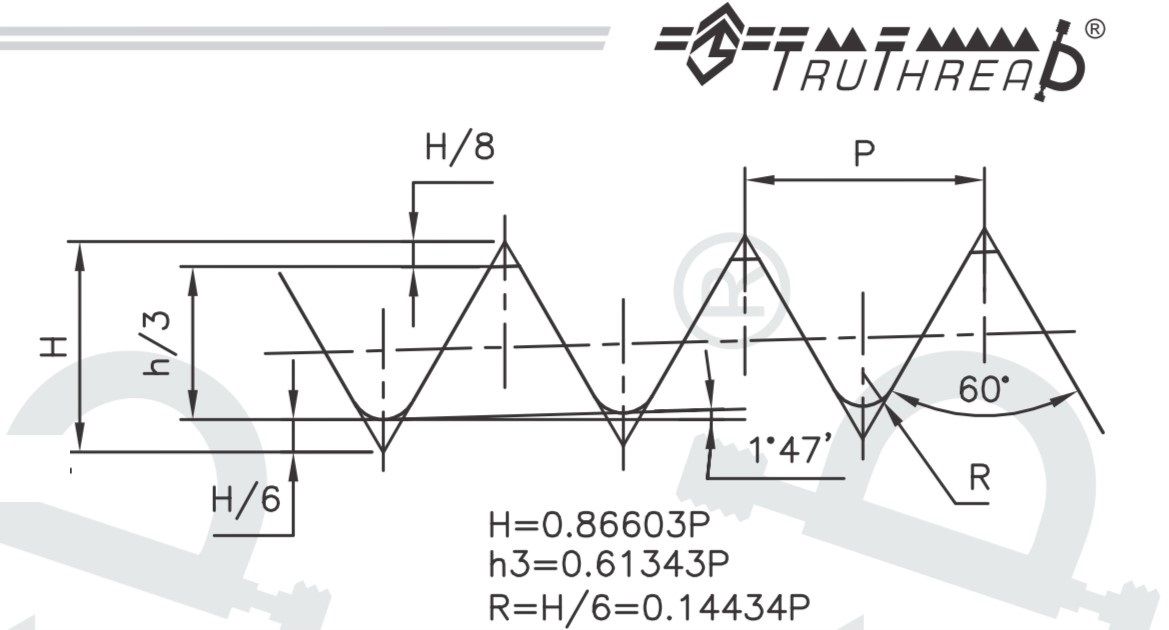

External threads are Taper & Internal Threads are parallel. For Internal threads, Thread profile is similar to ISO Metric Threads.

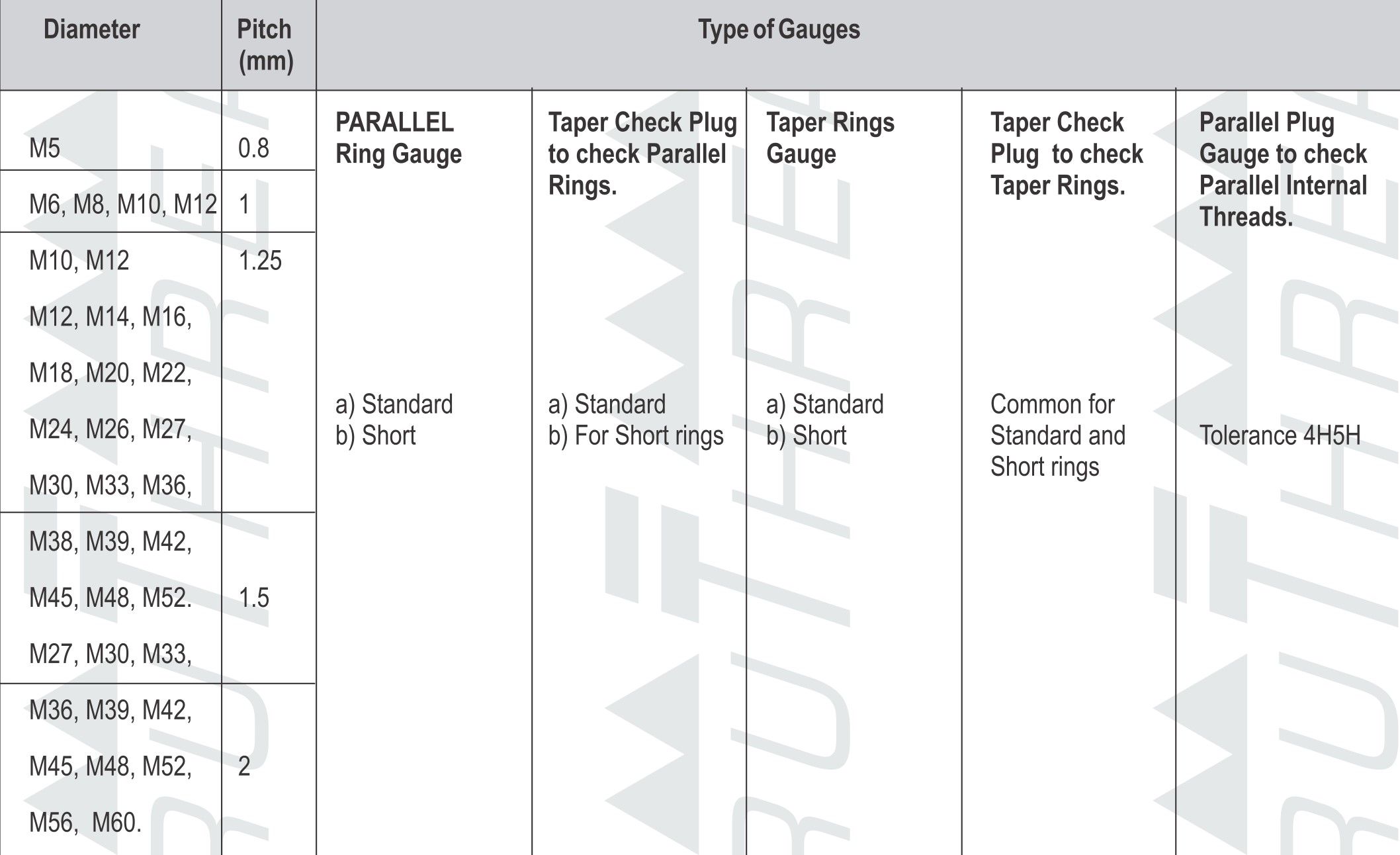

Manufacturing Range

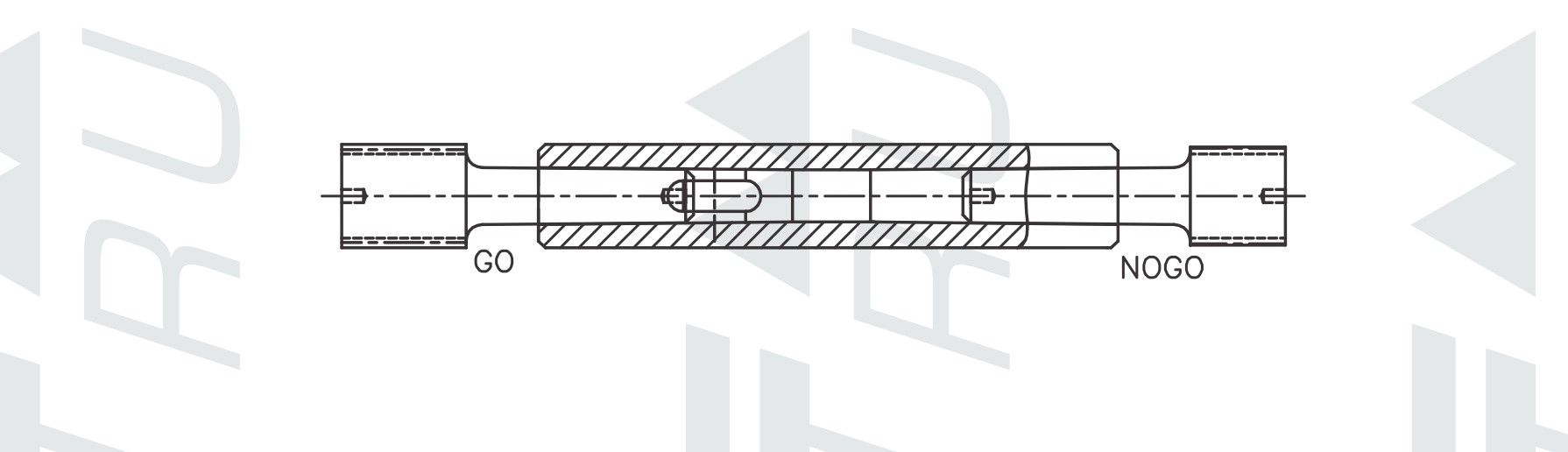

Gauging.

External Taper Threads of work piece can be checked by either,

Gauging.

External Taper Threads of work piece can be checked by either,

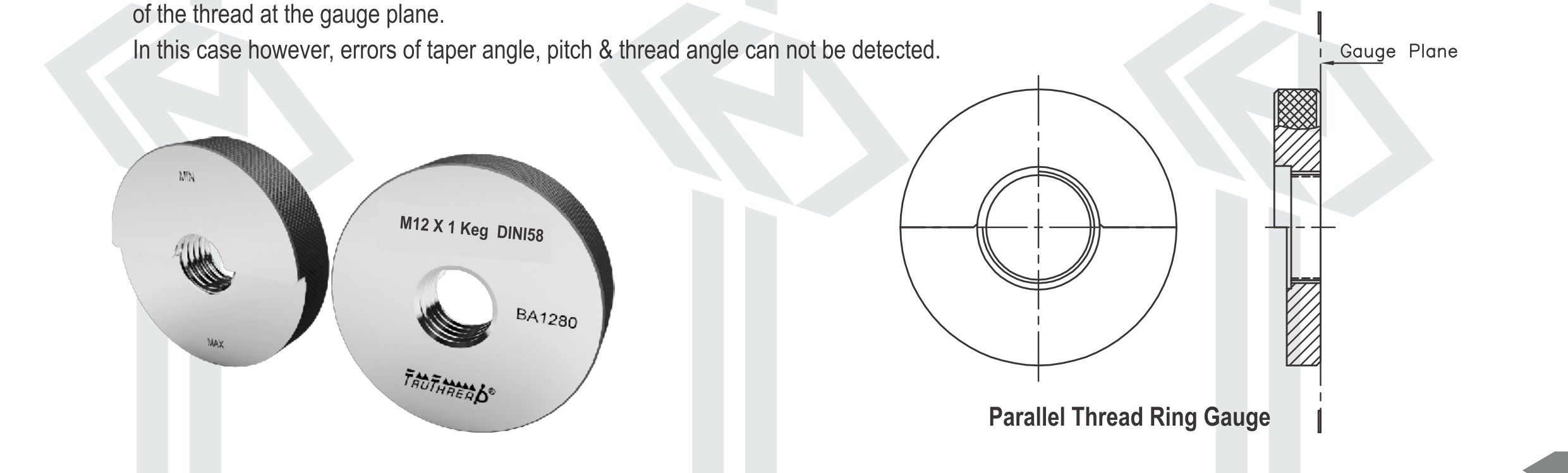

Parallel Thread Ring Gauge (Standard/Short).

The design of this ring is specified in DIN 158 Part 2 - 1997 standard.

The limitation of parallel ring gauge is, it checks only the function of the thread at the gauge plane.

In this case however, errors of taper angle, pitch & thread angle can not be detected.

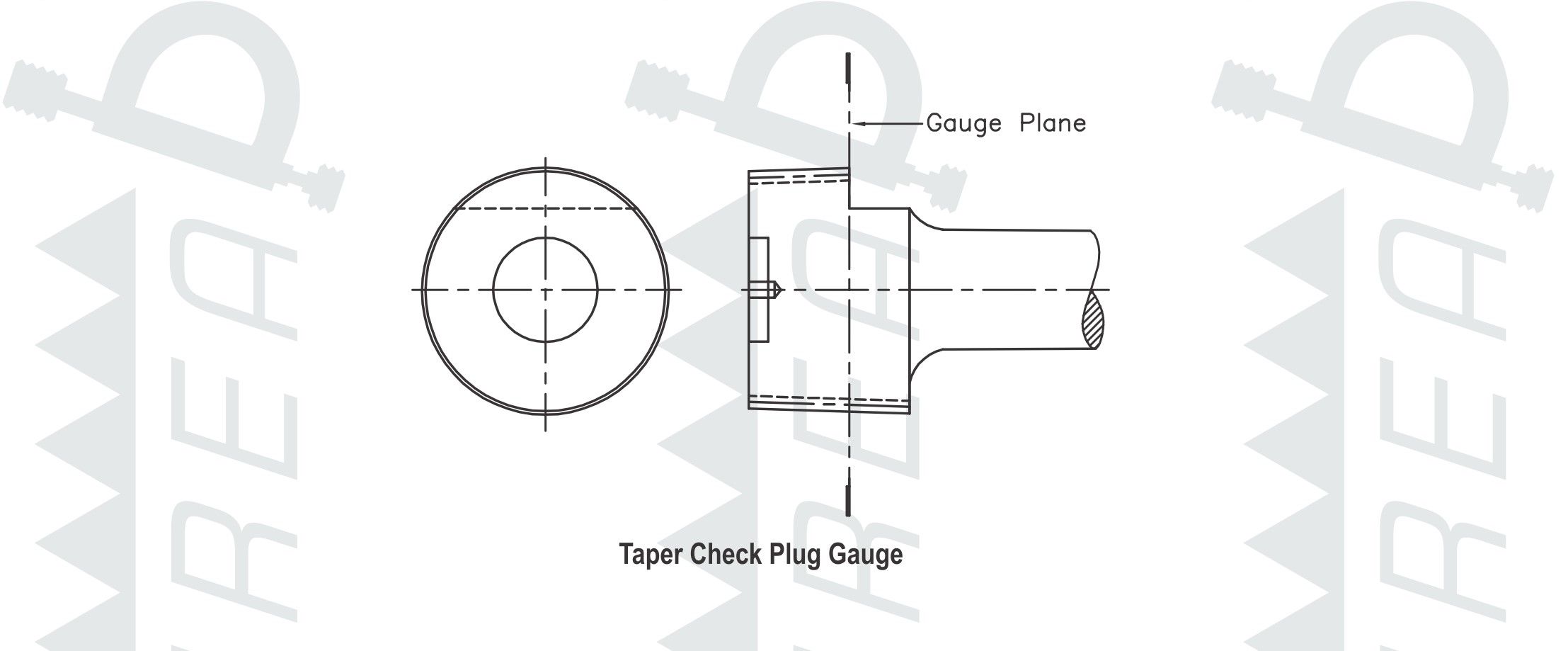

Taper Check Plug Gauge (Standard/Short)

Taper Check Plug Gauge is used to check NEW or worn out parallel Thread Ring Gauge.

Internal parallel Threads of work piece can be checked by Parallel Plug Gauge of tolerance class 4H5H. The Gauging practice of ISO Metric Thread Gauges is used for calculating Gauge size.

Use of M KEG Taper gauges in different industries

M KEG Taper Gauges occupy an important place in many industries due to their unique purpose. One of the main directions of their application is the installation and maintenance of oil nipples. In this context, it is important to ensure reliable tightness of the connection to avoid leakage of liquids and contamination that can damage the equipment.

M KEG thread taper gauges play a key role in the inspection and control of taper threads. They allow you to make sure that the parameters of the thread meet the requirements of standards and specifications. Such control ensures the correct and safe functioning of lubrication systems, which is of great importance for the duration and efficiency of the equipment.

It is also important to note that the conical shape of these gauges plays a crucial role in creating a reliable hermetic connection, where every detail is important. M KEG threaded conical gauges are therefore an indispensable tool for technical processes where tightness and reliability are important aspects. Learn more about our product range.