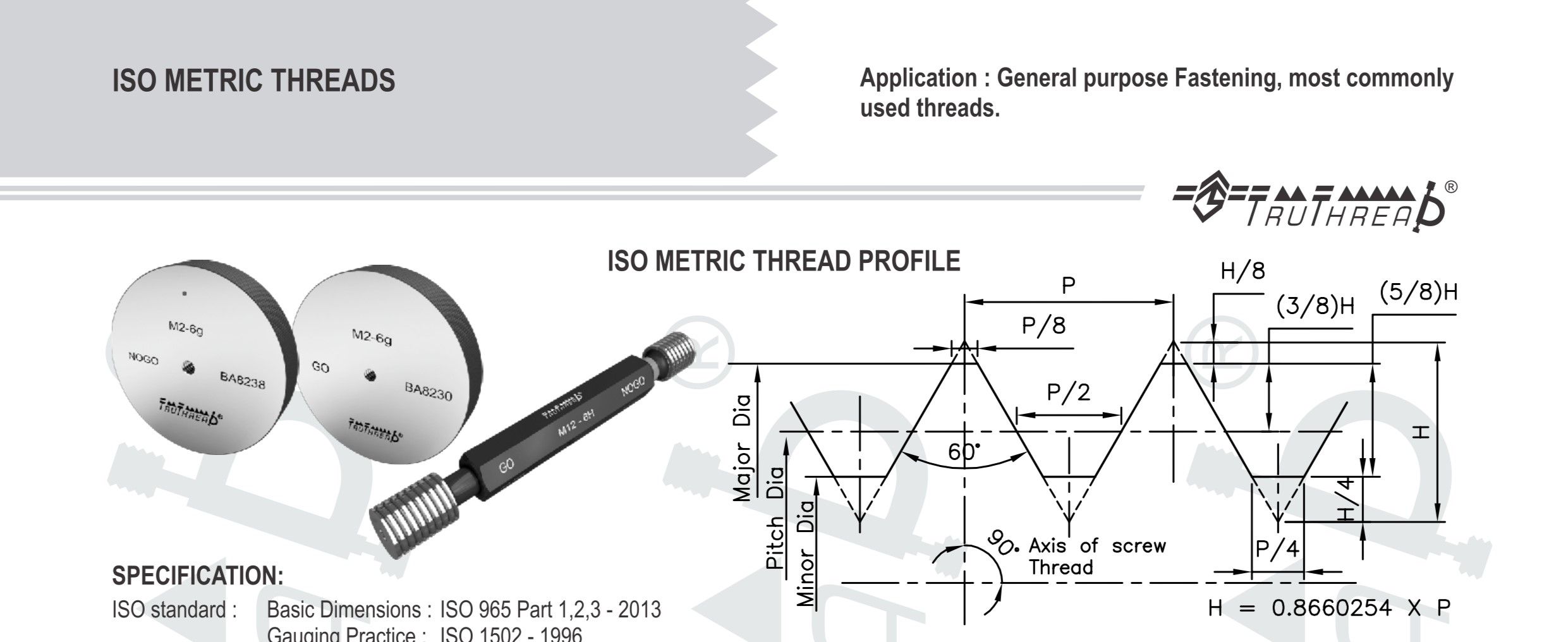

TruThread ISO Metric gauges

Metric gauges are indispensable tools for measuring and controlling the dimensions of metric thread parts. They are used in industrial production and repair work, where the accuracy of the thread is critical for the proper connection of components.

Metric thread gauges conforming to ISO or DIN standards have special threads that allow accurate measurement of thread diameter and pitch.

The use of metric thread gauges helps to avoid defects and shortcomings in the final products, ensuring high quality and reliability of connections. These simple but effective tools are indispensable assistants for engineers, mechanics and manufacturers, ensuring that high standards of work with thread parts are met. Thanks to metric gauges, production is able to achieve high accuracy and compliance with the requirements of standards, which helps to improve the quality of finished products and satisfy the needs of customers.

Thread gauges M, MF and MJ: differences and scope of use

The use of varieties of thread gauges M, MF and MJ is an integral part of the process of quality control of thread connections in production. They differ in their shape and metric characteristics:

M Gauge (Metric): This is a typical metric thread gauge, where the M stands for "metric". For example, M6 means a thread with a diameter of 6 mm. It is widely used in many engineering and industrial applications.

Gauge MF (Metric Fine): MF thread gauge has the same metric diameter, but with an increased diameter pitch, intended for connecting parts with high loads and strength requirements.

Gauge MJ (Metric with increased accuracy, where J means rounded root of external thread): Gauge MJ also has a metric diameter, but with increased manufacturing accuracy. It is used in additional measuring and precision applications where high precision connections are required.

These different types of thread gauges allow engineers and manufacturers to choose the best option for specific tasks, taking into account the strength, accuracy and ease of installation of the connections.

Metric thread gauges M and MF: standards and tolerances

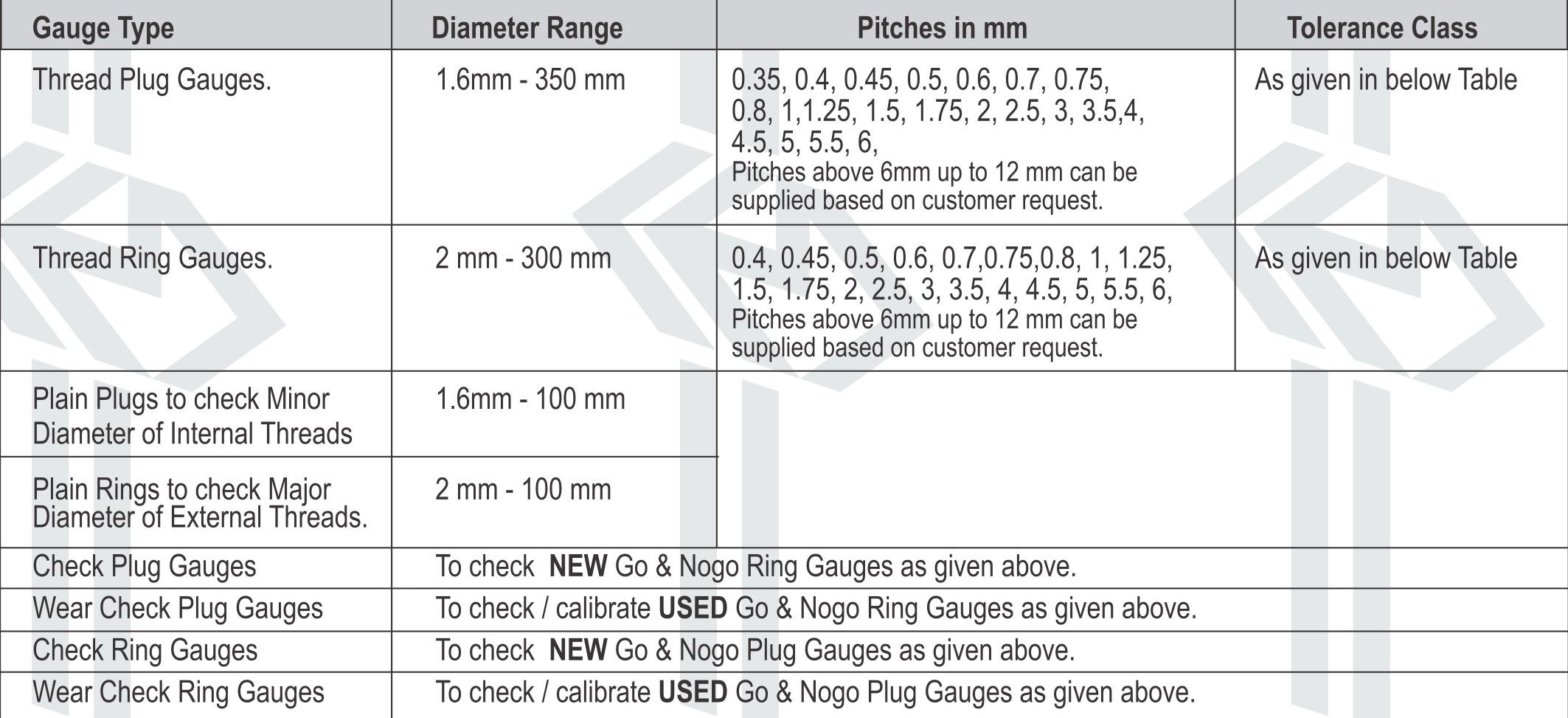

ISO Standard: Basic dimensions: ISO 965 Part 1,2,3 - 2013 Gauging Practice: ISO 1502 - 1996

Indian Standard: Basic dimensions: IS 14962 Part 1- 2018, Part -2&3 - 2001 Gauging Practice: Is 2334 - 2001

DIN Standard: Basic Dimensions & Gauging Practice: DIN 13 - 1999

ANSI standard: Basic dimensions: ANSI / ASME B 1.13 M Gauging Practice: ANSI / ASME B 1.14 M - 1984

BS Standard: Basic dimensions: B.S. 3643 Part I&II - 2007 Gauging Practice: B.S. 919 Part III - 2007

ANSI & BS Standards use unilateral tolerances for gauges. We manufacture them only according to individual customer orders and with a stipulated minimum number of units.

JIS Standard: Basic dimensions: JIS BO205 & JIS B 0209 Gauging Practice: JIS B0251 - 1998

JIS Standard: Gauging Practice JIS B 0251 - 1975 & JIS B0252 - 1996 Tolerance class - I,II & III & two grades Machine work & Inspection are recommended.

Gauges are marked as

Go Plug - Common for Working & Inspection (GP) - GPI, GPII, GPIII Nogo Plug for Working (WP) - WPI, WPII, WPIII Nogo plug for Inspection (IP) - IPI. IPII, IPIII

Go Ring - Common for Working & Inspection (GR) - GRI, GRII, GRIII Nogo Ring for Working (WR) - WRI, WRII, WRIII Nogo Ring for Inspection (IR) - IRI, IRII, IRIII

Measuring devices according to the outdated JIS standard are manufactured at the customer's request.

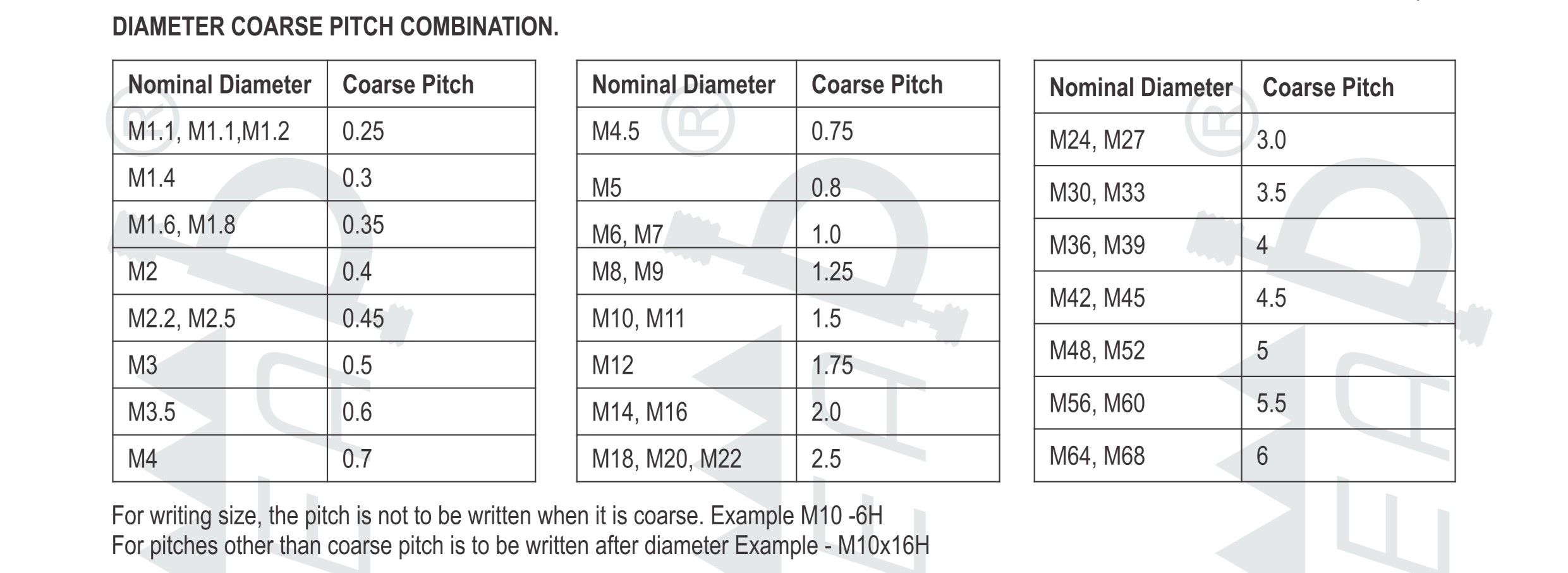

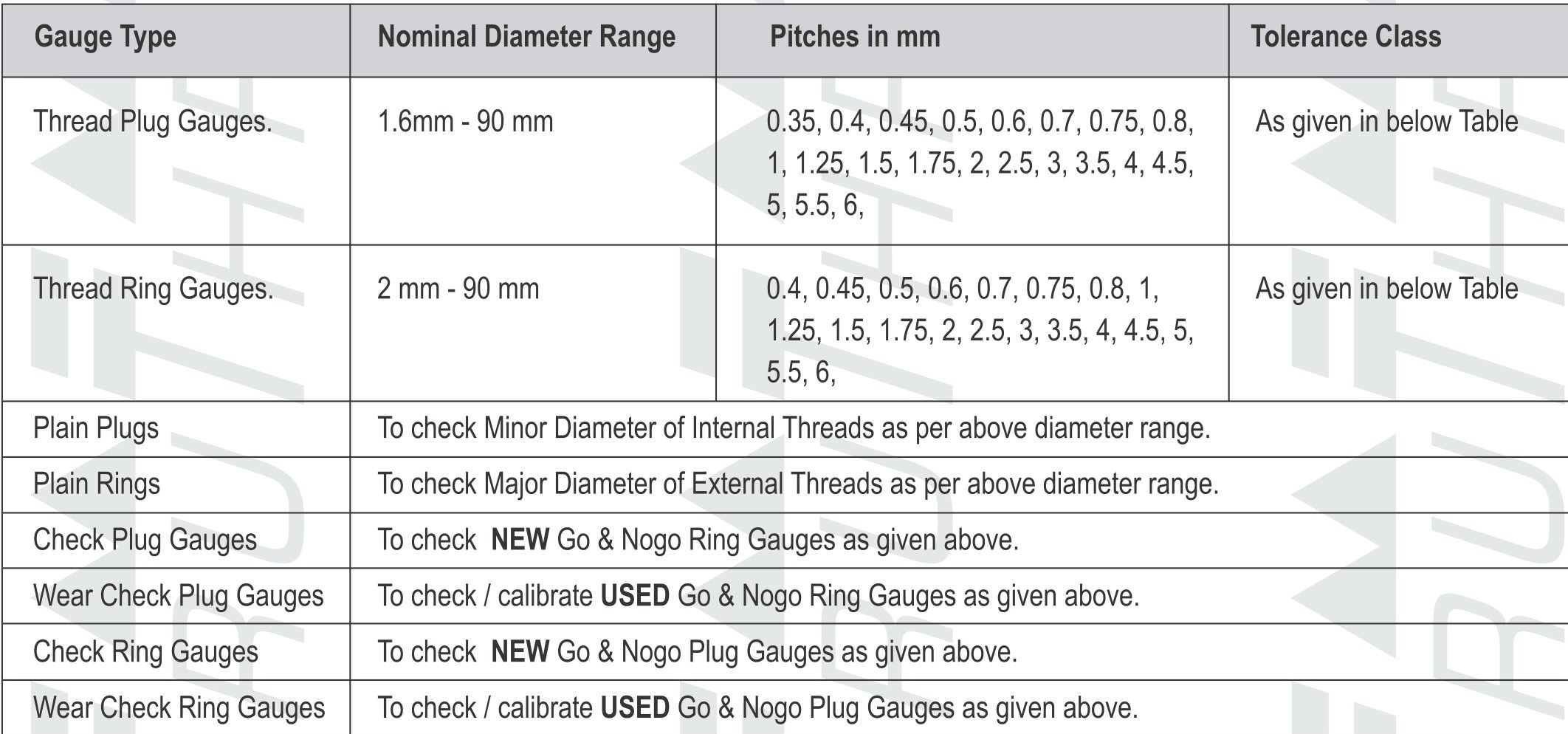

We manufacture ISO metric gauges according to the following parameters:

- customer specified Pitch Diameters

- modified pitch diameters to check components Before coating / Plating OR components After coating / plating

- tolerance class 6AZ, 6AX (Internal Threads / Thread Plugs) & 6az (External Threads / Thread Rings)

- external threads / thread rings of high temperature application as per IS 9965-1981

- interference fit gauges as per IS 2186-1985

Manufacturing range

Diameter Coarse Pitch Combination

For writing size the pitch is not to be written when it is coarse. Example, M10-6H For pitches other than coarse pitch is to be written after diameter. Example, M10x1 6H

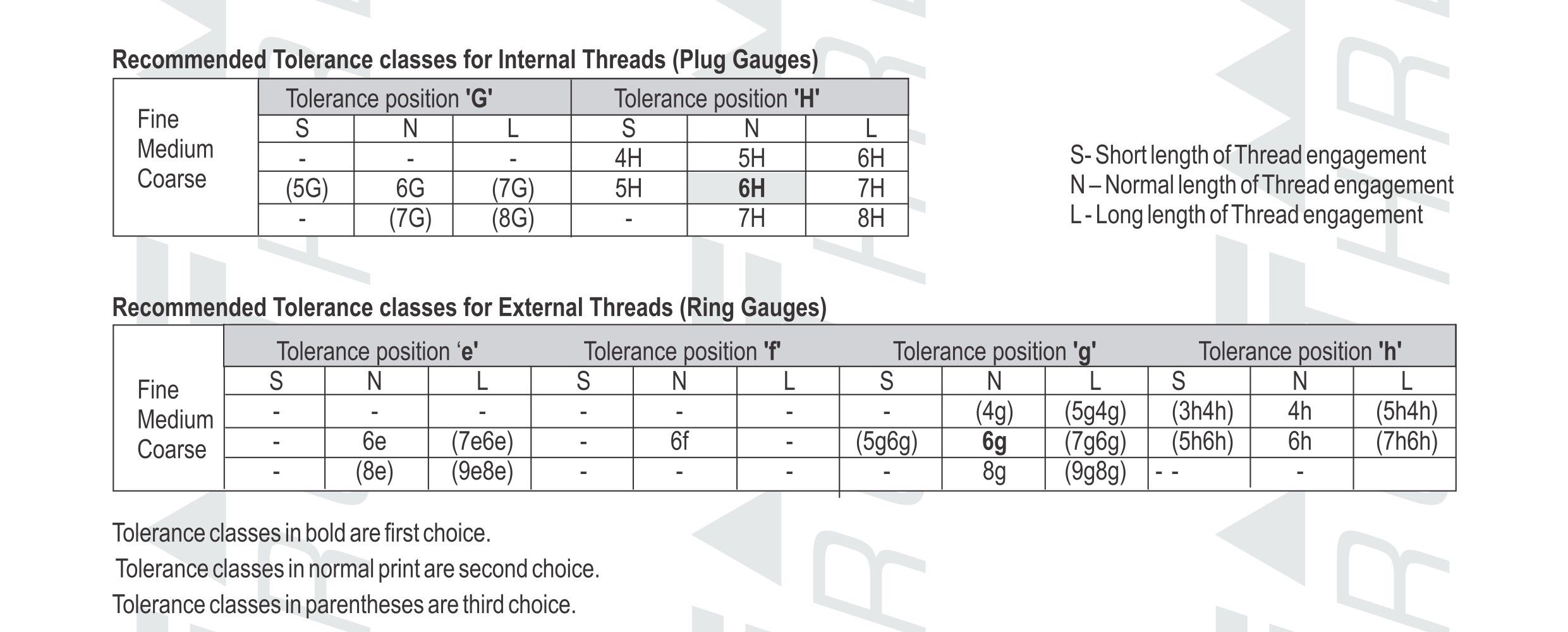

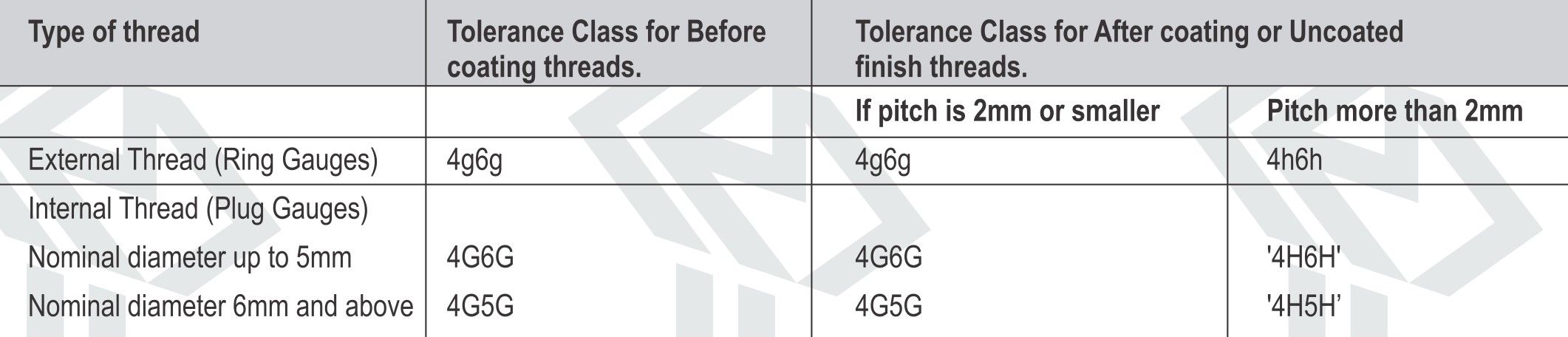

Recommended Tolerance Classes for Internal Threads (Plug Gauges) and for external Threads (Ring Gauges)

S - Short length of Thread engagement

N - Normal length of Thread engagement

L - Long length of Thread engagement

Tolerance classes in bold are first choice

Tolerance classes in normal print are second choice

Tolerance classes in parentheses are third choice

Metric plug gauges: description, characteristics, use

Metric plug thread gauges are special tools used to control the diameter size and depth of internal threads on parts. They are cylindrical in shape with serrations or grooves that exactly match metric standards for threading.

Metric plug thread gauges ensure that internal threads are checked for correct shape, dimensions and standards. They help ensure that the manufactured thread holes in the parts meet the established technical requirements and ensure reliable connections with thread elements.

To use metric plug thread gauges, their size must match the inside diameter of the thread hole being tested. After inserting the gauge into the thread hole, the depth of the thread is measured.

With metric thread plug gauges provide high quality and precision thread control, which is critical for the safe and efficient use of thread connections in a variety of manufacturing industries and applications.

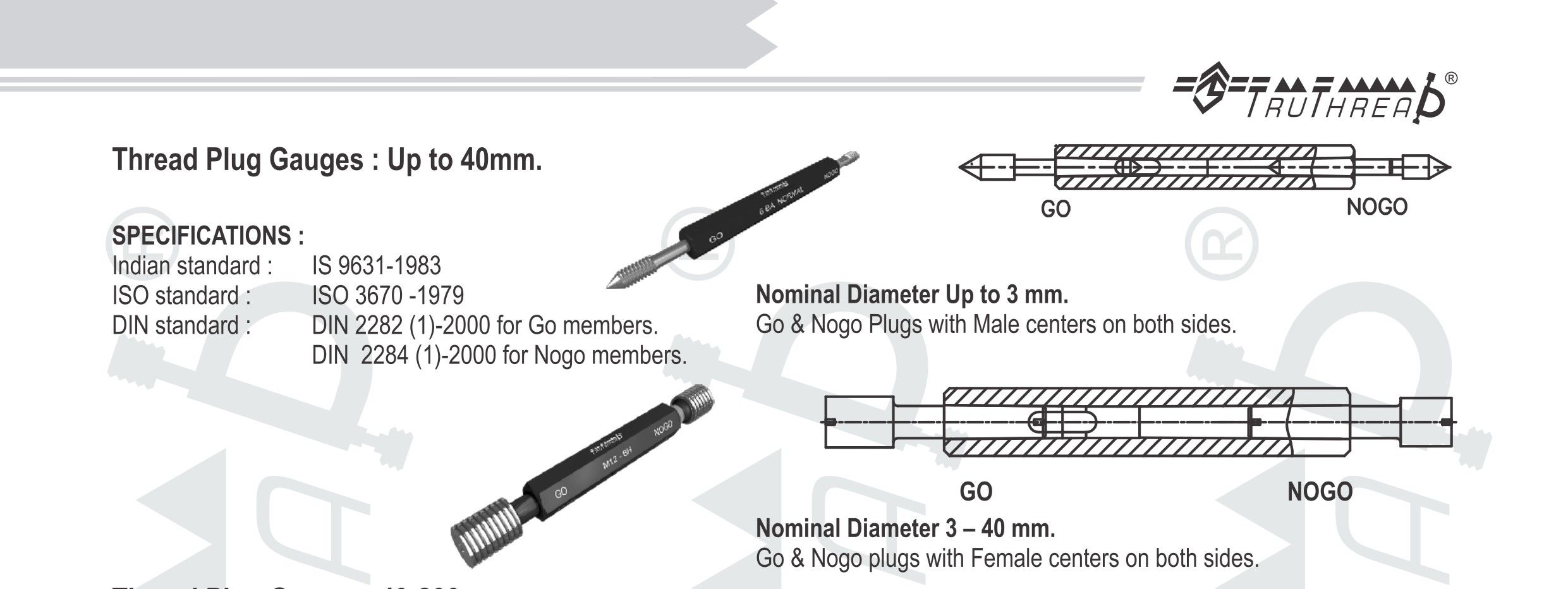

Thread plug gauges up to 40 mm

Specifications: Indian Standard: IS 9631 - 1983 ISO standard: 3670 - 1979 DIN standard: DIN 2282 (1) - 2000 for Go elements. DIN 2284 (1) - 2000 for Nogo elements

Nominal diameter up to 3 mm Go&Nogo plug gauges with Male centers on both sides

Nominal diameter 3-40 mm Go&Nogo plug gauges with Female centers on both sides

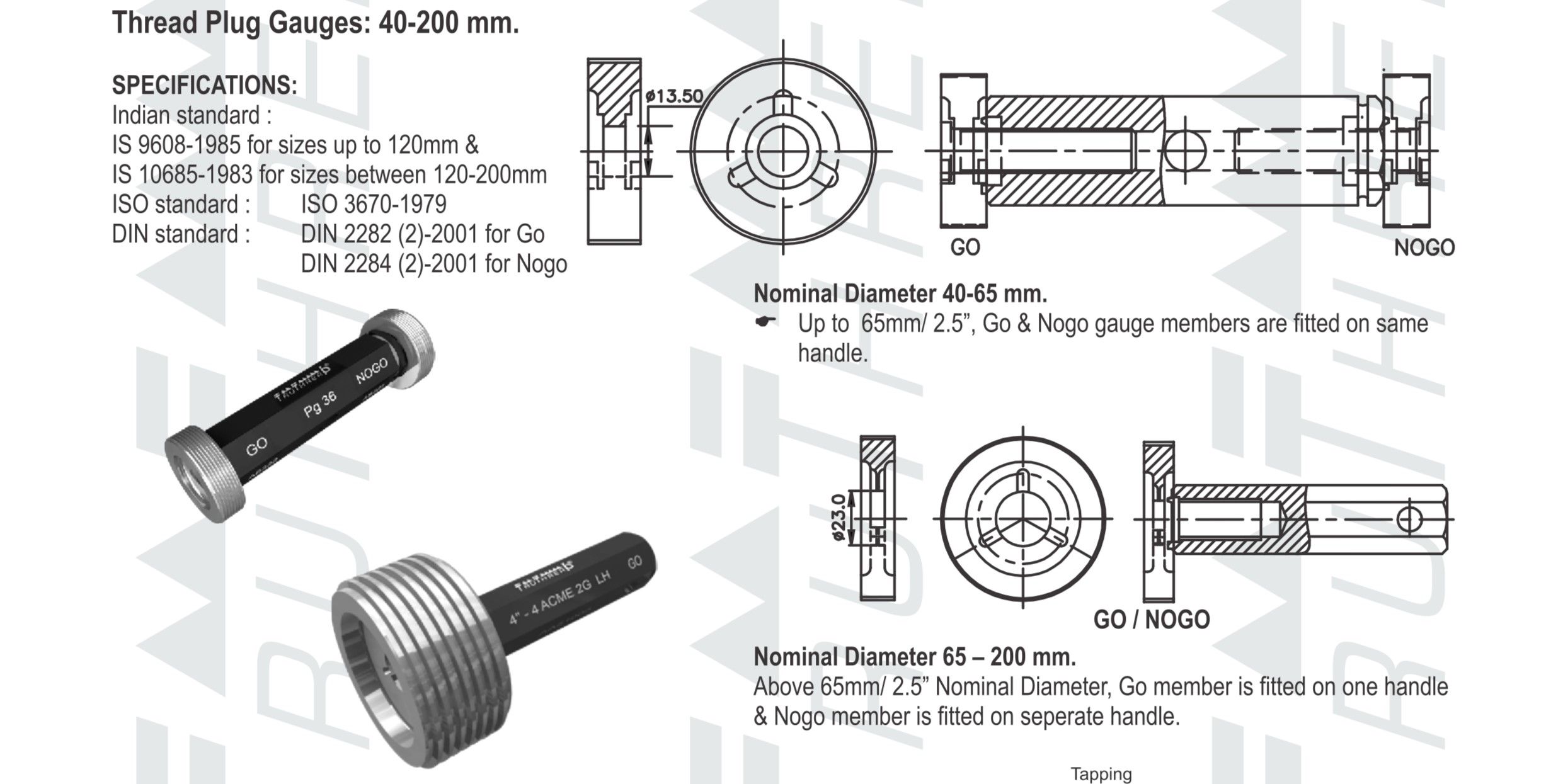

Thread plug gauges 40mm-200mm

Specifications: Indian Standard: IS 9608-1985 for sizes up to 120mm & IS 10685-1983 for sizes between 120mm-200mm

ISO standard: ISO 3670-199 DIN standard: DIN 2282 (2)-2001 for GO. DIN 2284 (2)-2001 for Nogo

Nominal diameter 40mm-65mm Up to 65 mm/2.5” Go&Nogo gauge elements are fitted on same handle

Nominal diameter 65mm-200mm From 65mm/2.5” nominal diameter, the Go element is fitted on one handle and the Nogo element on a separate handle

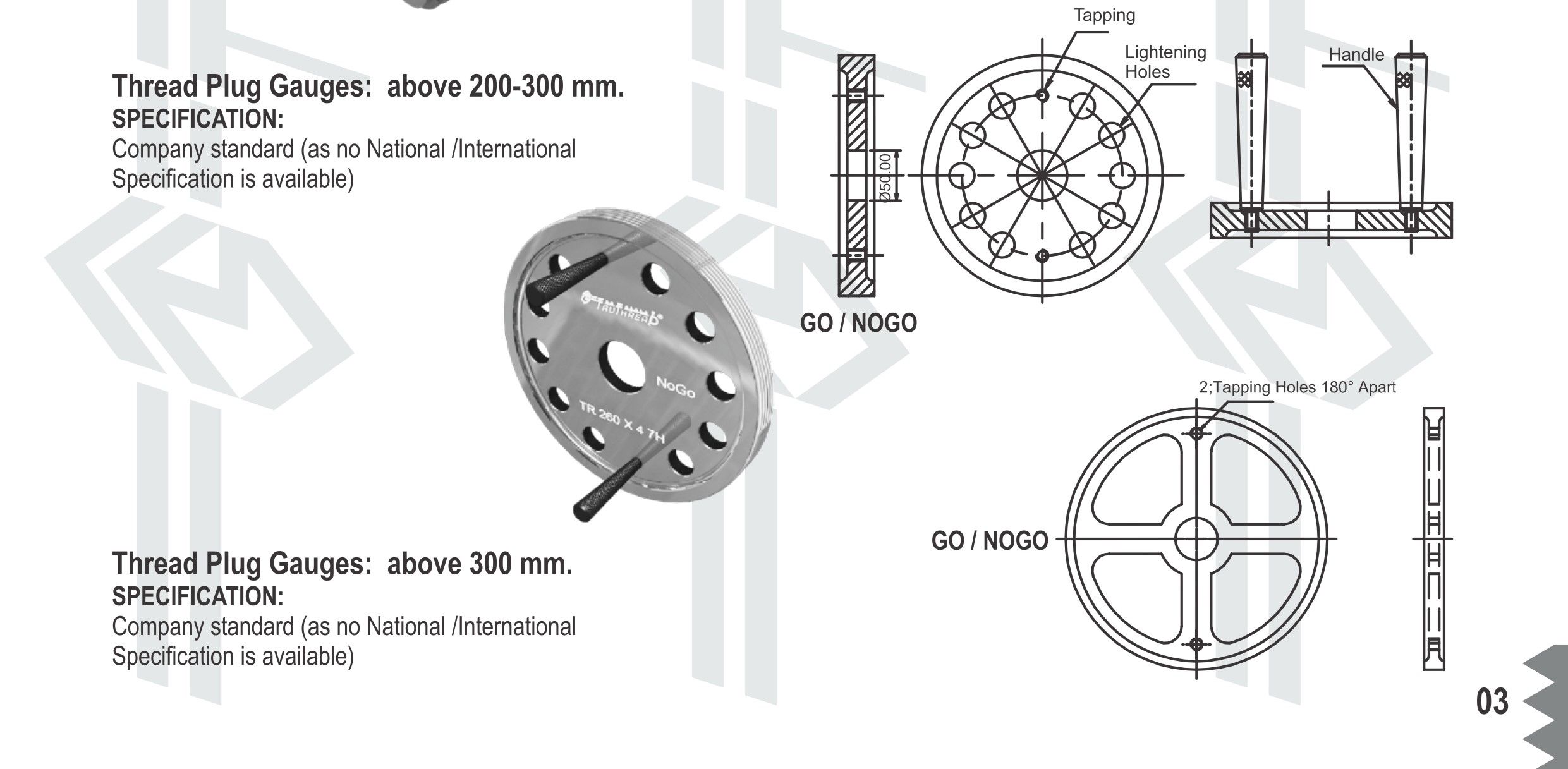

Thread plug gauges from 200-300 mm

Specifications: Company standard (as national/international specification not available)

Metric ring gauges: description, characteristics, use

Ring thread gauges are important tools in the field of inspection of thread connections. Their use allows you to check and measure metric threads with great accuracy and reliability. We manufacture ring gauges from strong hardened steel with a hardness of 60-62 HRc.

The use of thread ring gauges is widespread in various industries where the accuracy and reliability of thread connections are critical. Manufacturers of machines, cars, airplanes, as well as other industrial enterprises widely use these gauges to check parts before their assembly, thereby ensuring high quality and reliability of finished products. Due to their ease of use and efficiency, ring thread gauges remain an integral component in ensuring the quality of production and structural connections in industrial production.

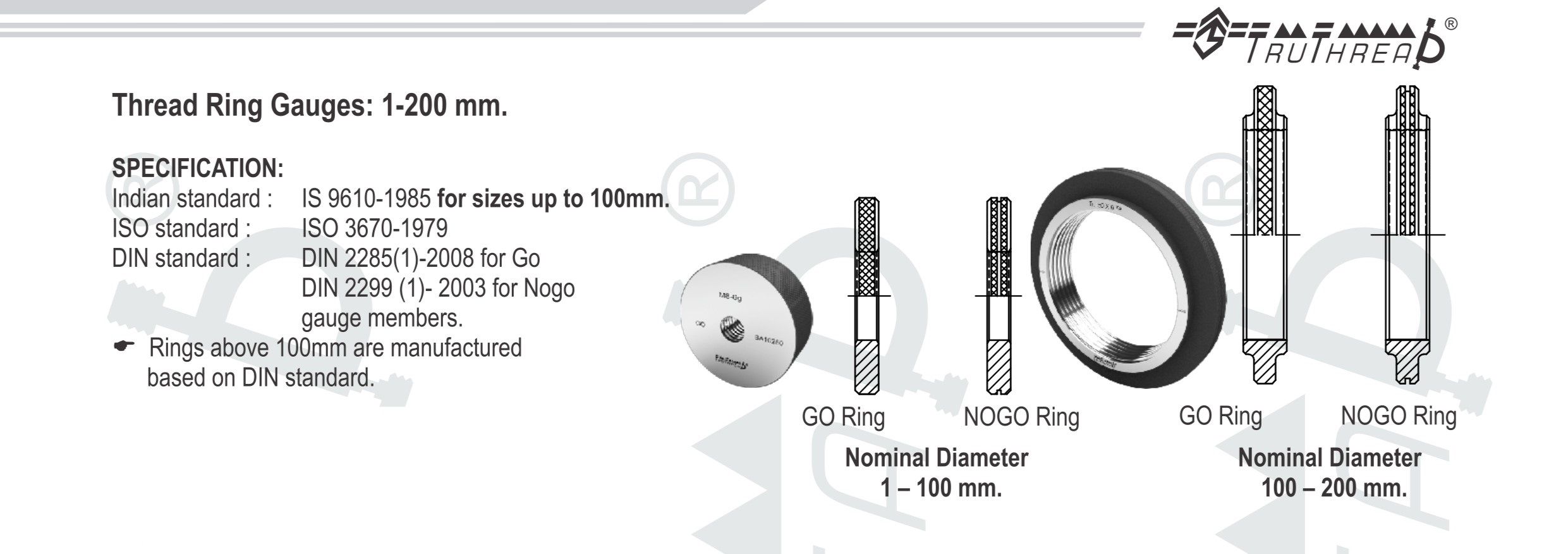

Ring thread gauges 1mm-200mm

Specifications: Indian standard: IS 9610-1985 for sizes up to 100mm ISO standard: 3670-1979 DIN standard: DIN 2285 (1) - 2008 for GO. DIN 2299 (1) - 2003 for Nogo

Ring gauges with a diameter of 100 mm or more are manufactured based on DIN standards

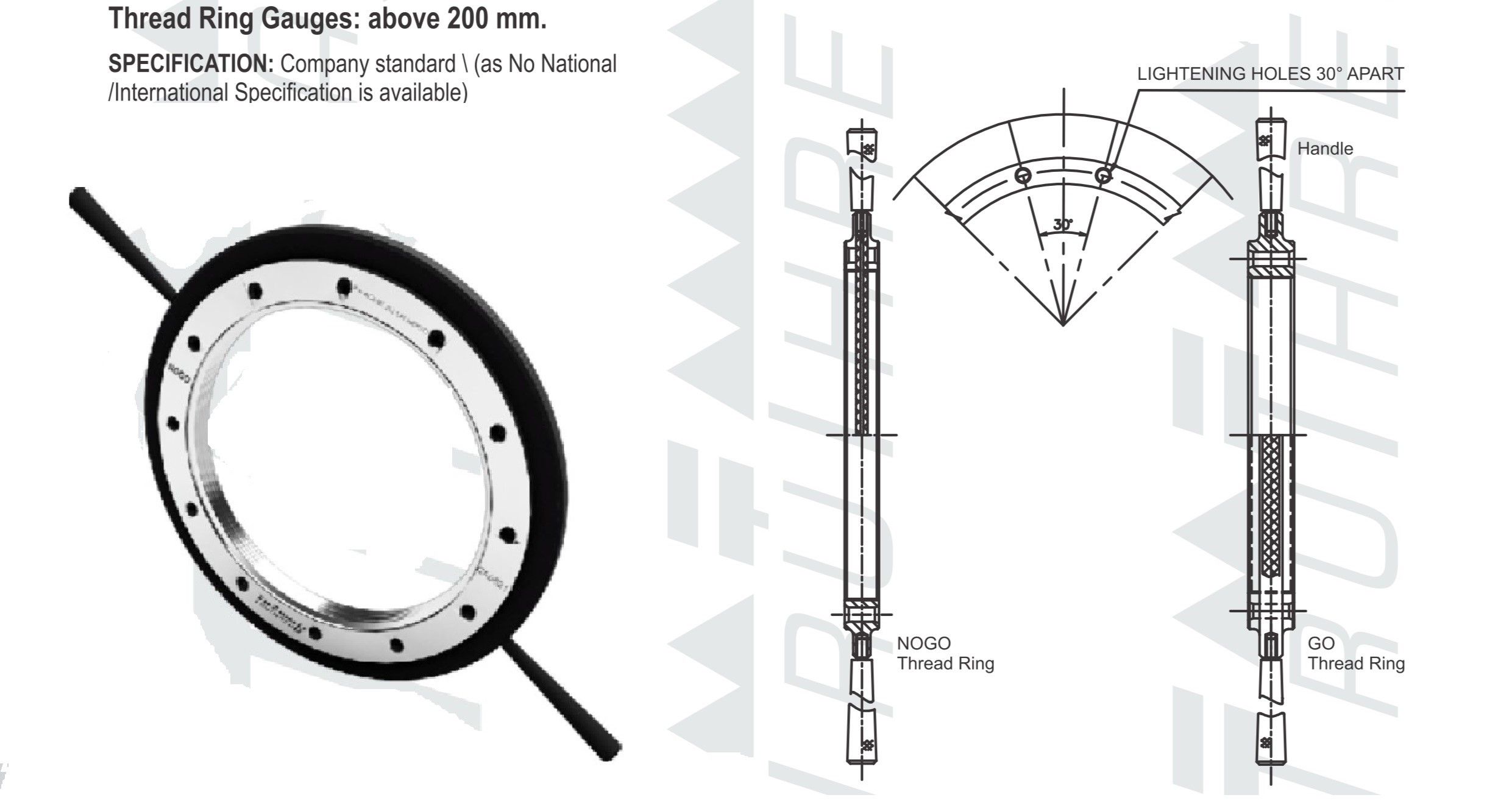

Thread ring gauges above 200 mm

Company standard (as national/international specification not available)

MJ metric thread gauges: the highest measurement accuracy

MJ thread gauges are among the most accurate and high-quality tools for measuring and checking metric threads. "MJ" stands for "high precision metric". These gauges are used where high precision and reliability of connections are important, such as aerospace, medical, electronics and other complementary applications.

The main advantage of MJ thread gauges is their ability to provide extremely accurate measurement of thread joint parameters such as diameter, pitch, thread depth, as well as checking the smoothness and regularity of the thread. This allows manufacturers to achieve high product quality, reduce waste and avoid problems associated with unreliable connections. Due to their high accuracy, MJ thread gauges are often used in laboratory settings where the highest level of detail and control over threading parameters is required. The use of these gauges helps achieve the highest quality standards and helps maintain a smooth and efficient production process.

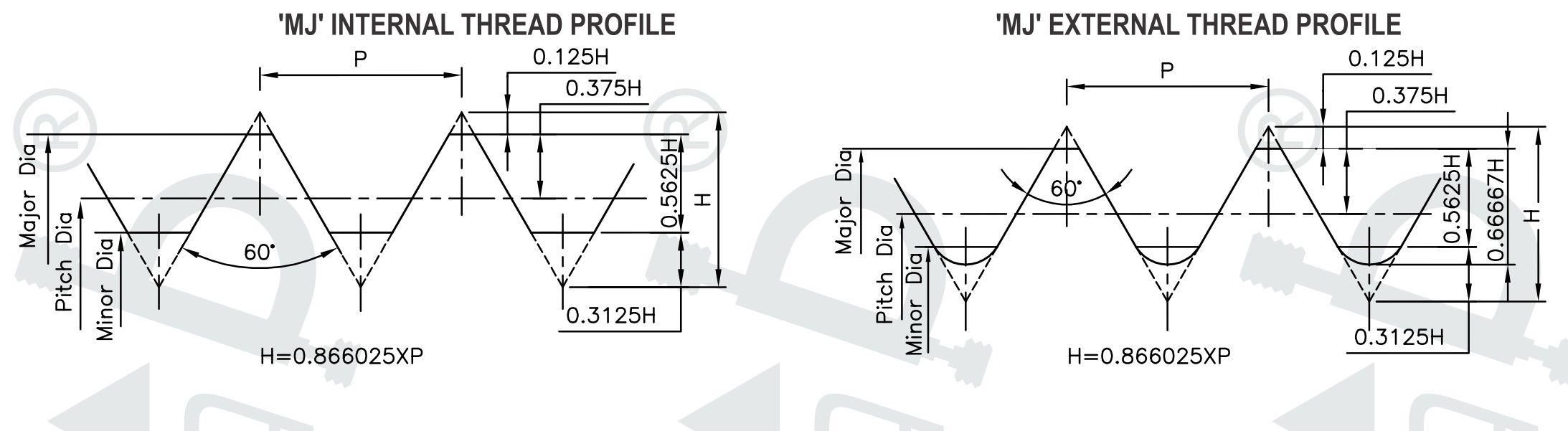

MJ internal thread profile | MJ external thread profile

Specifications: ISO 5855 - Part I,II,III - 1999, & Gauging practice ISO 10959 - 2016 ANSI B 1.21M - 1997 & ANSI B1.22M - 1985

Manufacturing range

Tolerance class

TruThread Europe offers a wide range of metric thread gauges for rings and plugs M, MF and MJ, which meet the highest quality standards and ensure accurate measurement of thread parameters. Our gauges are reliable and durable tools that help avoid defects and ensure stable and trouble-free operation of your production. With us, you can be sure of the accuracy and quality of the connections of your products, which contributes to the success of your business and the satisfaction of customer needs.