Gas gauges NGT: Ensuring tightness and safety of gas cylinders

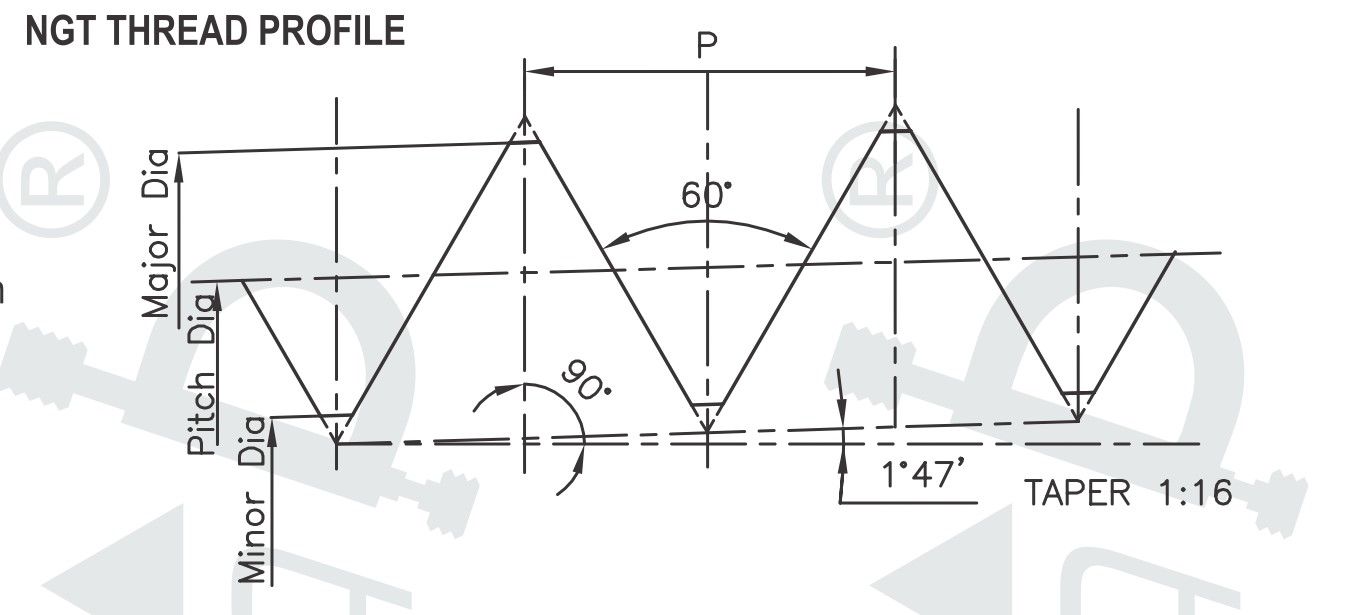

NGT gauges are an indispensable tool for testing gas cylinders. The National Gas Taper is used to check the valve stems of gas cylinders and the thread on the neck of the cylinder (the so-called 1:16 "taper" thread). Gauges contribute to safety and reliability in working with gas cylinders, allowing you to make sure that the equipment is always in good condition and ready for use.

This tool has a number of important applications, especially in industries where the safety and reliability of gas cylinders is critical. The use of NGT Gauges allows you to make sure that the valves of gas cylinders open and close properly, and that the threads on the neck of the cylinder are in excellent condition, which guarantees a tight connection.

Thanks to their accuracy and reliability, NGT Gauges help ensure safety when handling and storing gases in cylinders. They have become an integral part of equipment for specialized gas enterprises, medical institutions, as well as in other industries where gas cylinders are used.

NGT Gauges: technical specifications and drawings

Application: Used for checking Gas cylinder valve stems and cylinder neck threads (Taper 1 in 16)

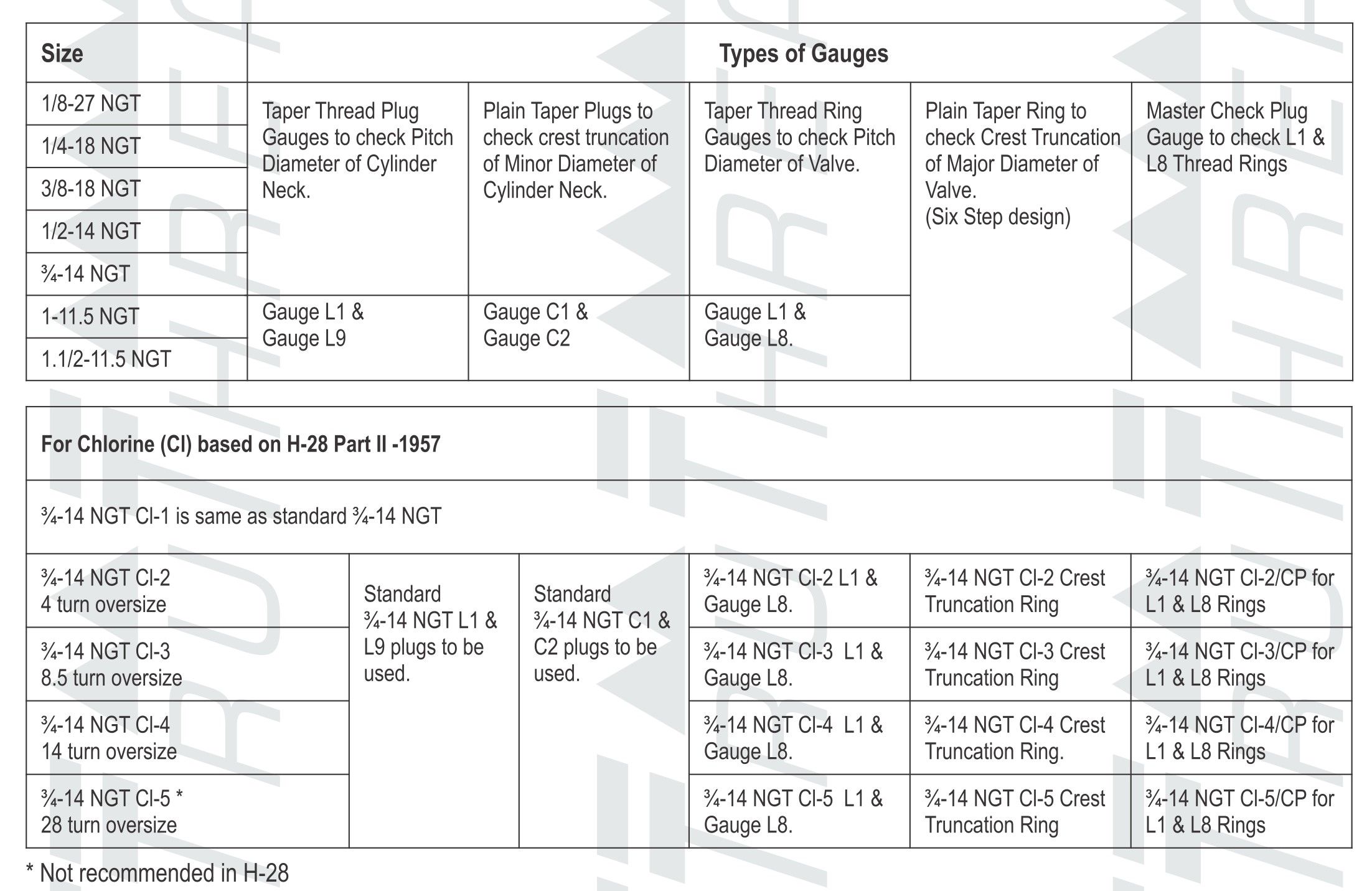

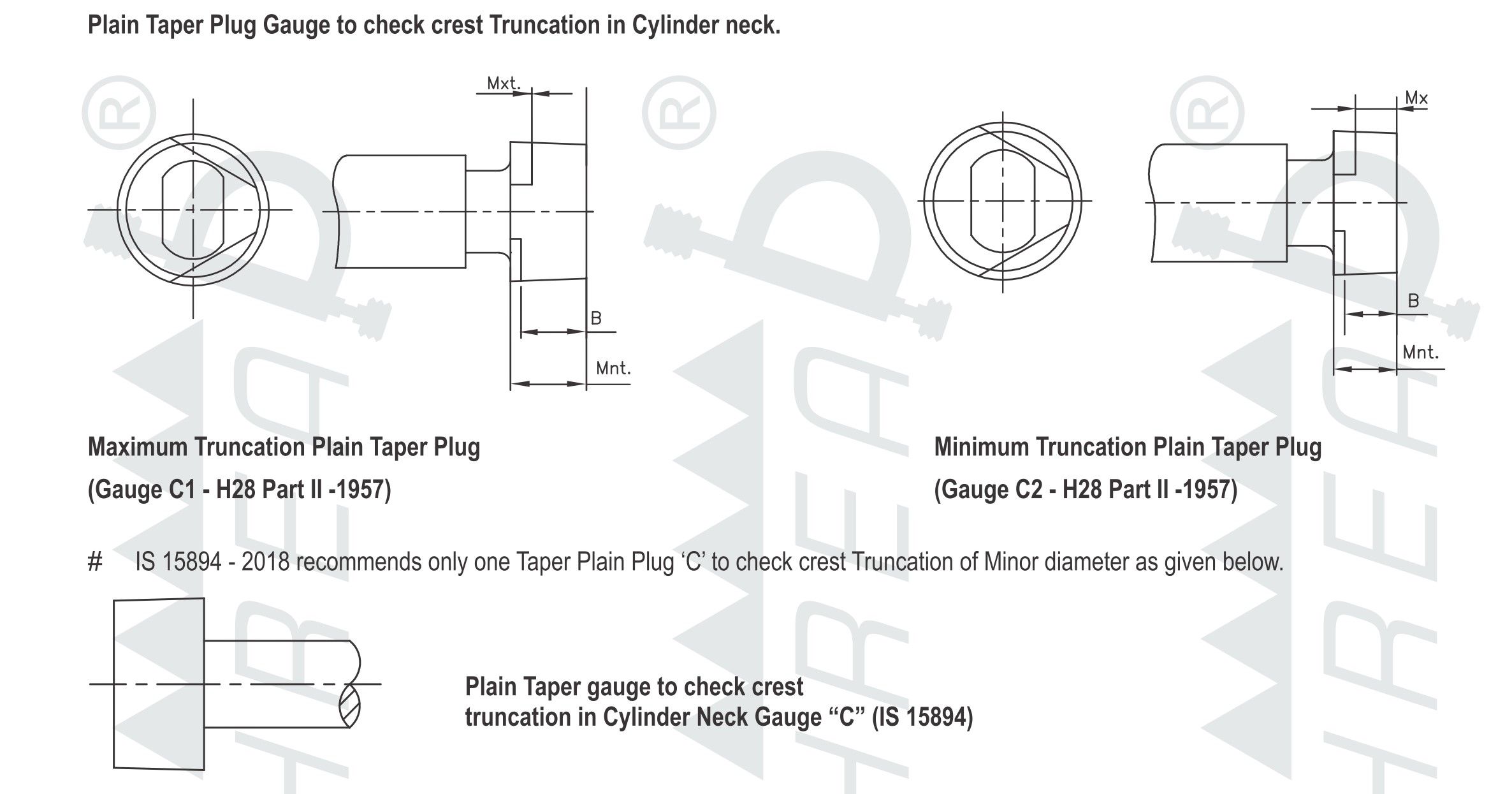

Specification (for Inspection gauges): Handbook H-28 Part II - 1957 / CGA V-1 - 2001 IS 15894 - 2018 Only * marked sizes from the given below table are covered in IS 15894. Balance sizes as per Handbook H-28

We manufacture gauges as per obsolete IS 9121 - 1979 based on specific customer requests.

Read More: What is the Difference Between Different Types of NGT Gauges?

Gauges for checking Internal Taper Threads of Cylinder Neck

1 - Thread plug gauge for checking Pitch Diameter in Cylinder Neck L1 (Gauge A as per IS 15894)

2 - Full Form Taper Thread Plug Gauge for checking Thread in Cylinder Neck L9 (Gauge B as per IS 15894)

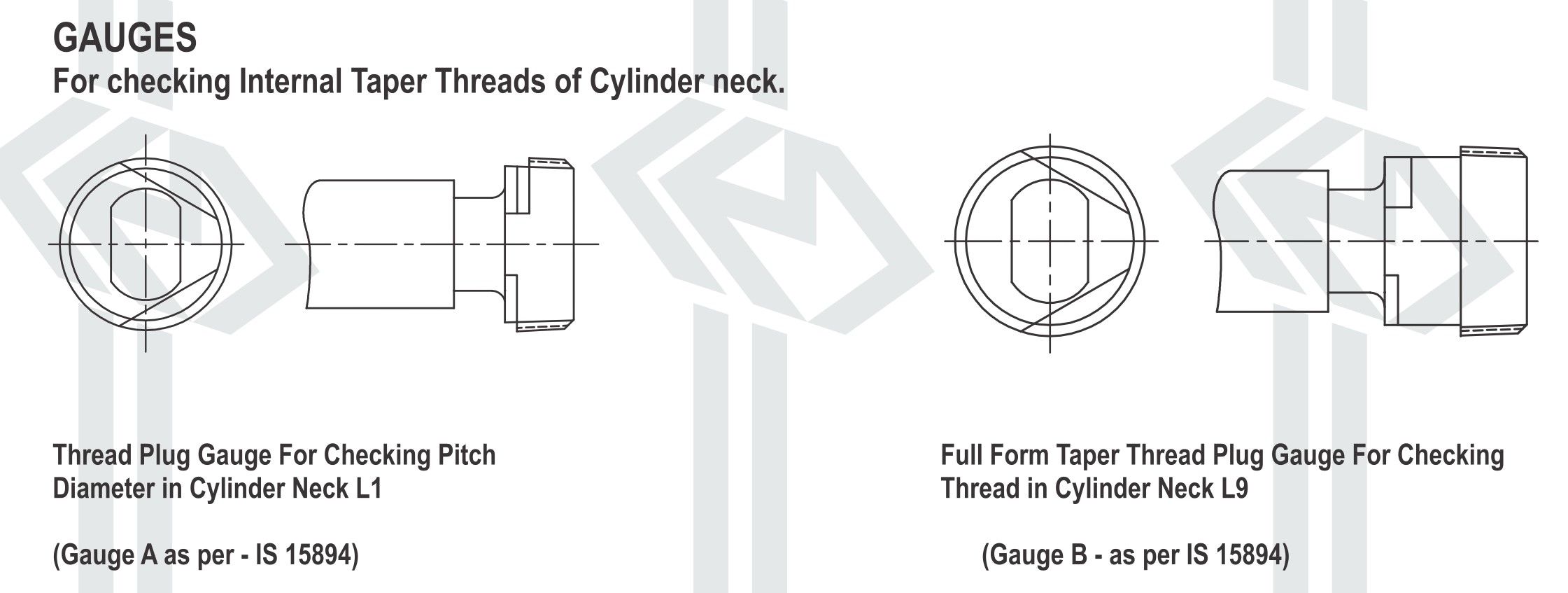

Plain Taper Plug gauge to check crest Truncation in Cylinder Neck

1 - Maximum Truncation Plain Taper Plug (Gauge C1 H-28 Part II - 1957) 2 - Minimum Truncation Plain Taper Plug (Gauge C2 H-28 Part II - 1957)

IS 19894 - 2018 recommends only one Taper Plain Plug C to check crest Truncation of minor diameter as given below.

3 - Plain Taper Gauge to check crest truncation in Cylinder Neck Gauge “C” (IS 15894)

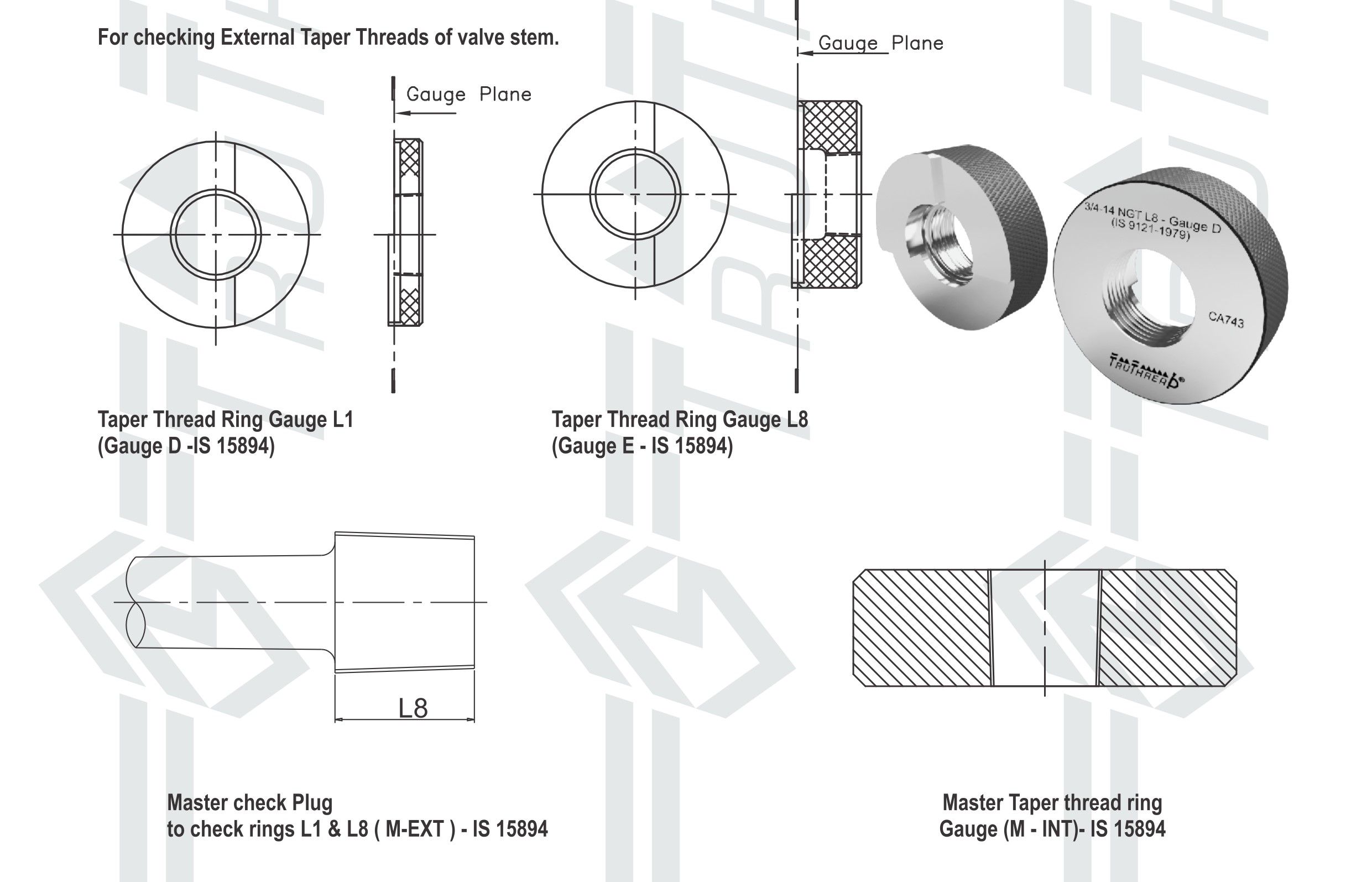

For Checking external Taper Threads of valve stem

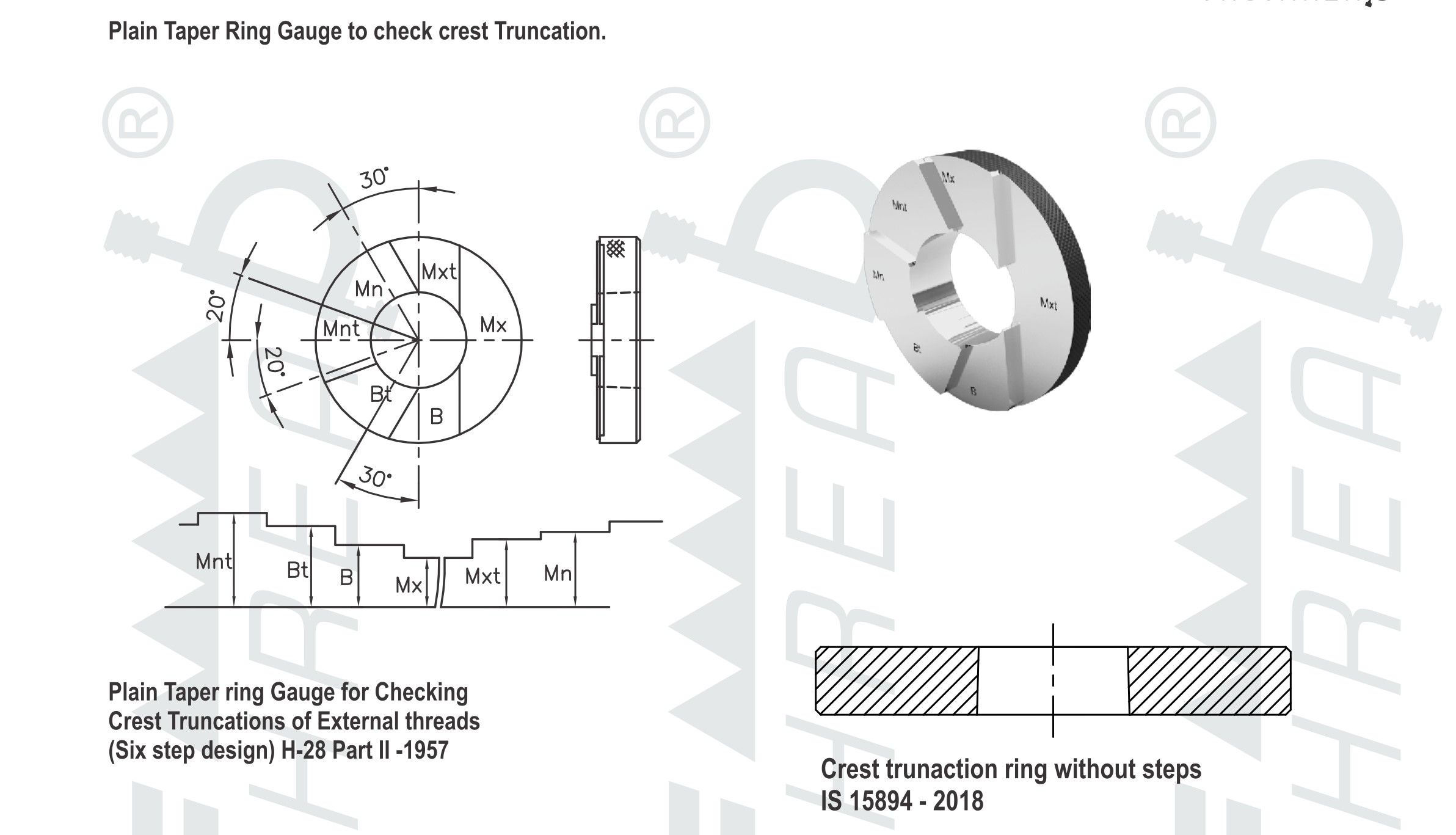

Plain Taper Ring Gauge to check crest Truncation

1- Plain Taper Ring gauge for checking Crest Truncation of External Threads (six step design) H-28 Part II - 1957 2 - Crest Truncation Ring without steps IS 15894 - 2018

Application and Importance of NGT gauges in working with gas cylinders

NGT gauges (National Gas Taper) are essential tools for checking and servicing gas cylinders and valves. There are different types of NGT Gauges designed to test different aspects of gas cylinders. The main types include gauges for checking cylinder neck threads and for checking gas cylinder valves.

NGT Gauges are noted for their high accuracy, making them reliable tools for determining whether gas cylinders meet safety and quality standards. The main application of NGT Gauges is to check the condition and correctness of the threads on the neck of gas cylinders. This is important to ensure the tightness and safety of gas storage and transportation.

Using NGT Gauges helps avoid gas leaks, which can be dangerous. This is especially important in industries where gasses are used for industrial or medical purposes. They are widely used in industry in chemical plants and medicine for gas equipment and medical gasses. These tools contribute to the implementation of regulations and standards regarding safety when working with gas cylinders. They help prevent accidents and gas-related accidents.

In general, NGT Gauges are essential tools for working safely with gas cylinders and ensuring their reliability and compliance with quality standards.