NPT thread gauges for pipes: TruThread Europe manufacturer range

NPT (National Pipe Thread) thread gauges are an important tool in the field of pipeline engineering and pipe installation. They are intended for measuring and checking threads on external or internal surfaces of pipes, fittings and other piping components that use threaded connections. The main function of NPT thread gauges is to check the correctness of thread production and penetration depth.

One of the important aspects of using NPT thread gauges is to ensure a tight connection between pipes or fittings. Correct threading and correct use of gauges help to avoid leaks and ensure system reliability. They are widely used in the production, installation and maintenance of pipeline systems, including water supply systems, gas supply systems, oil pipelines, pneumatic and hydraulic systems

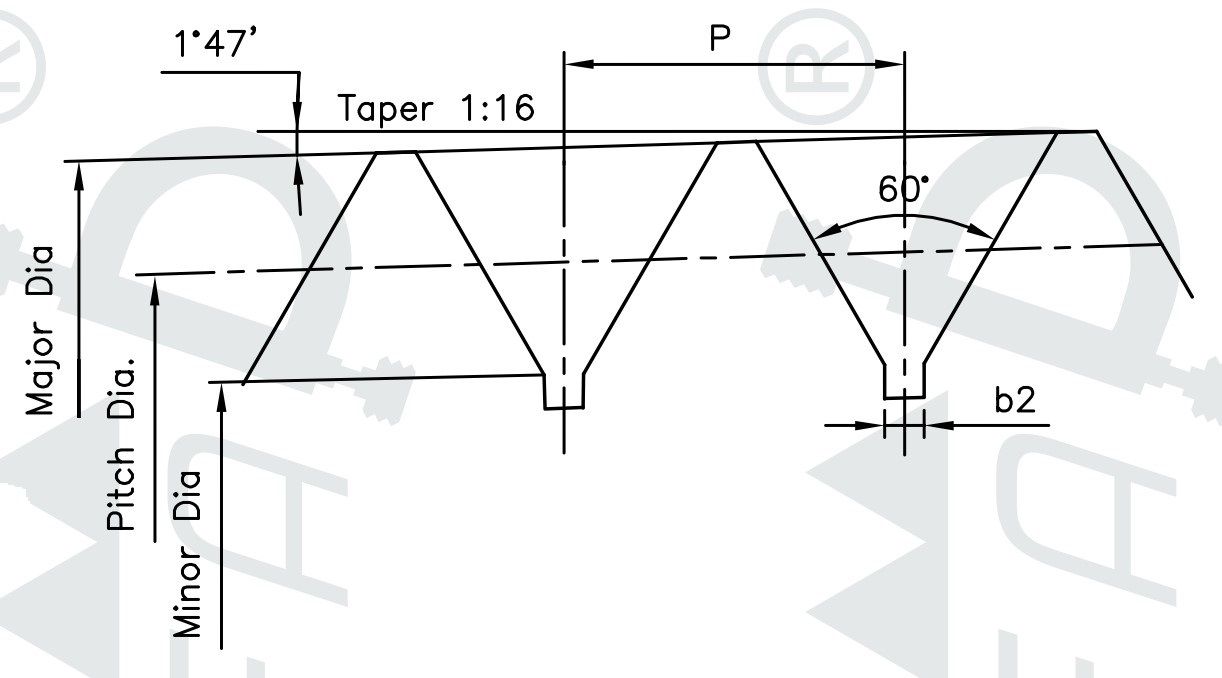

Technical characteristics of National Pipe Thread Gauges

NPT thread gauges adhere to standards set by the American National Standards Institute and other regulatory organizations. This ensures their compatibility and use in different industries and applications.

Specifications: ASME B1.20.1-2013 for Basic Type gauges and American Handbook H-28 Part II - 1957 for Step Limit Type gauges.

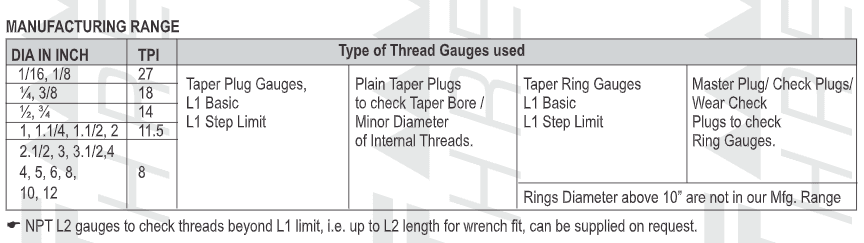

TruThread manufacturer range

NPT L2 gauges for checking the thread beyond the L1 limit, i.e. up to L2 length for wrench fit, can be produced at the customer's request.

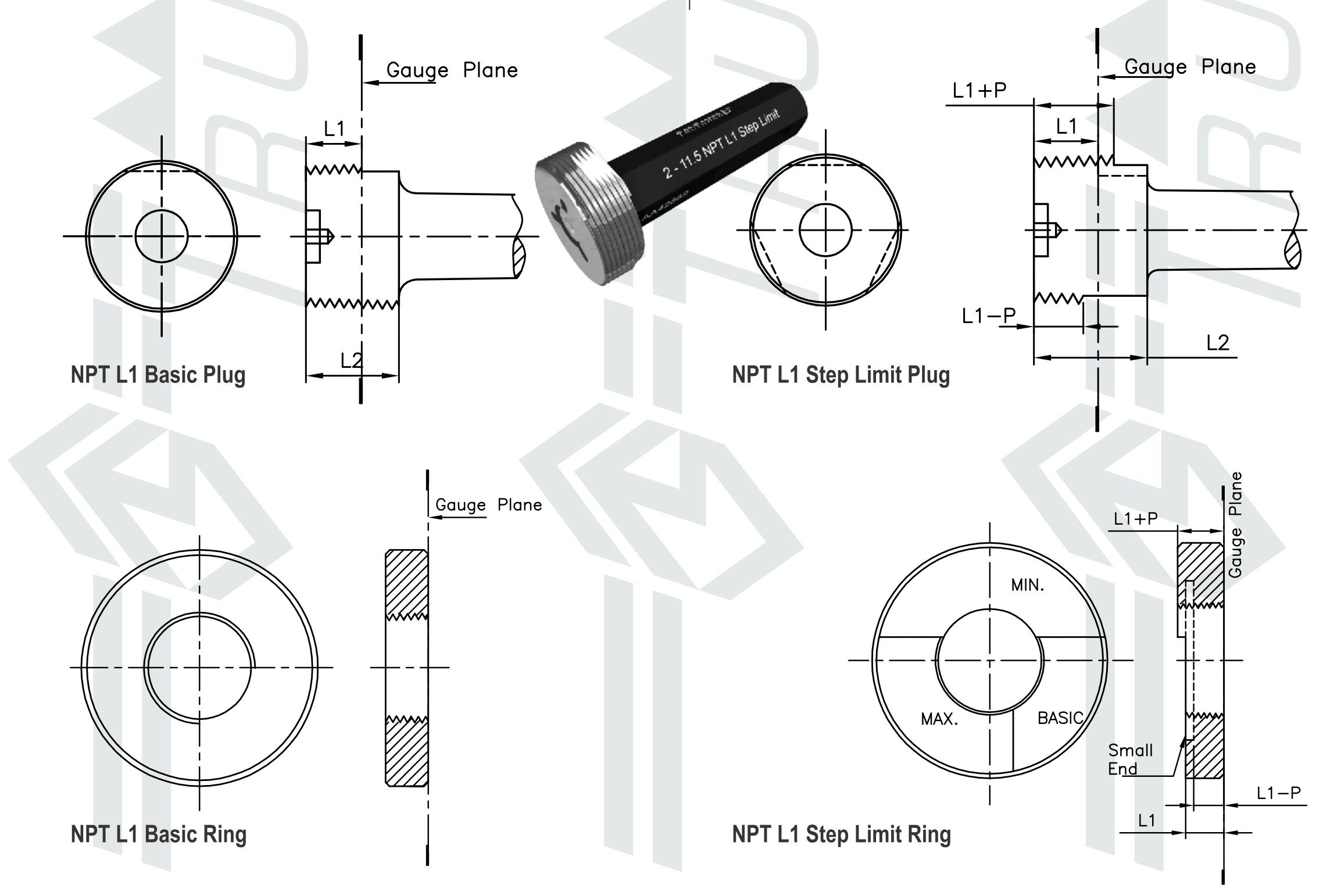

Thread gauges NPT Basic and NPT Step Limit

There are two main types of NPT thread gauges: Basic and Step Limit. A basic type is used to check the basic size of components, while a limited type allows you to define minimum, basic and maximum dimensions, ensuring compliance with standards and correct connection.

Basic type: In this case, the gauge has only one step, which corresponds to the basic size of the component. This type helps to determine whether the pipe thread matches the basic size and allows you to determine whether the connection has been made correctly.

Limited type: The limited type gauge has three steps that correspond to the minimum, base, and maximum dimensions of the components. These steps help determine whether the pipe thread meets not only the basic size, but also the specified minimum and maximum dimensions. This is important in order to ensure proper compatibility and tightness of the pipe connection.

NPT thread gauges are an important tool for ensuring the quality and reliability of pipe connections in various industries and applications. They help maintain the safety and efficiency of pipeline systems, reducing the risk of leaks and breakdowns.