NPTF and PTF thread gauges for pipe systems

NPTF (National Pipe Thread Fuel) and PTF (Pipe Thread Form) thread gauges are important tools in the pipeline installation and maintenance industry. They allow you to check and maintain a high standard of threads on the external and internal surfaces of pipes and fittings.

They help to avoid potential problems such as leaks, malfunctions or insufficiently sealed connections, which can lead to serious consequences. Tightness and proper threading are becoming critical factors in ensuring the efficient operation and safety of pipeline systems, and in this context NPTF and PTF thread gauges play a key role.

Technical characteristics of NPTF / PTF gauges for pipelines

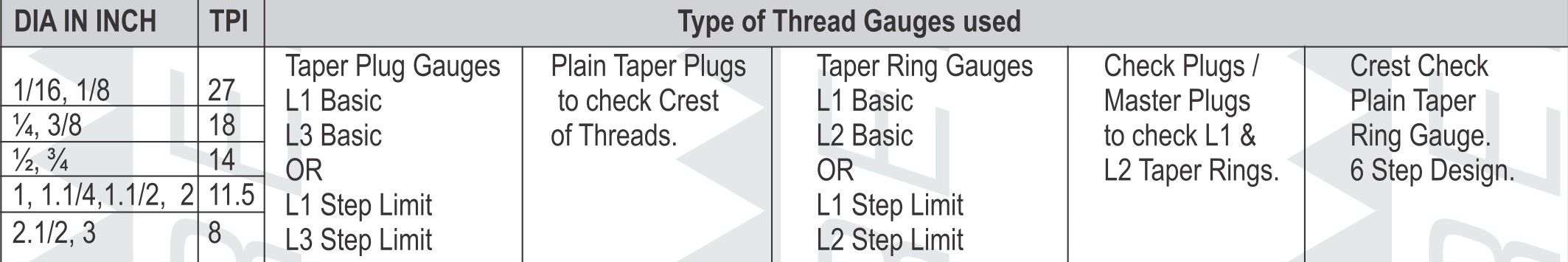

Specifications: ASME B1.20.6 - 1984 which is a metric translation of B1.20.5 - 1991 and H-28 Part II 1957

TruThread manufacturer range

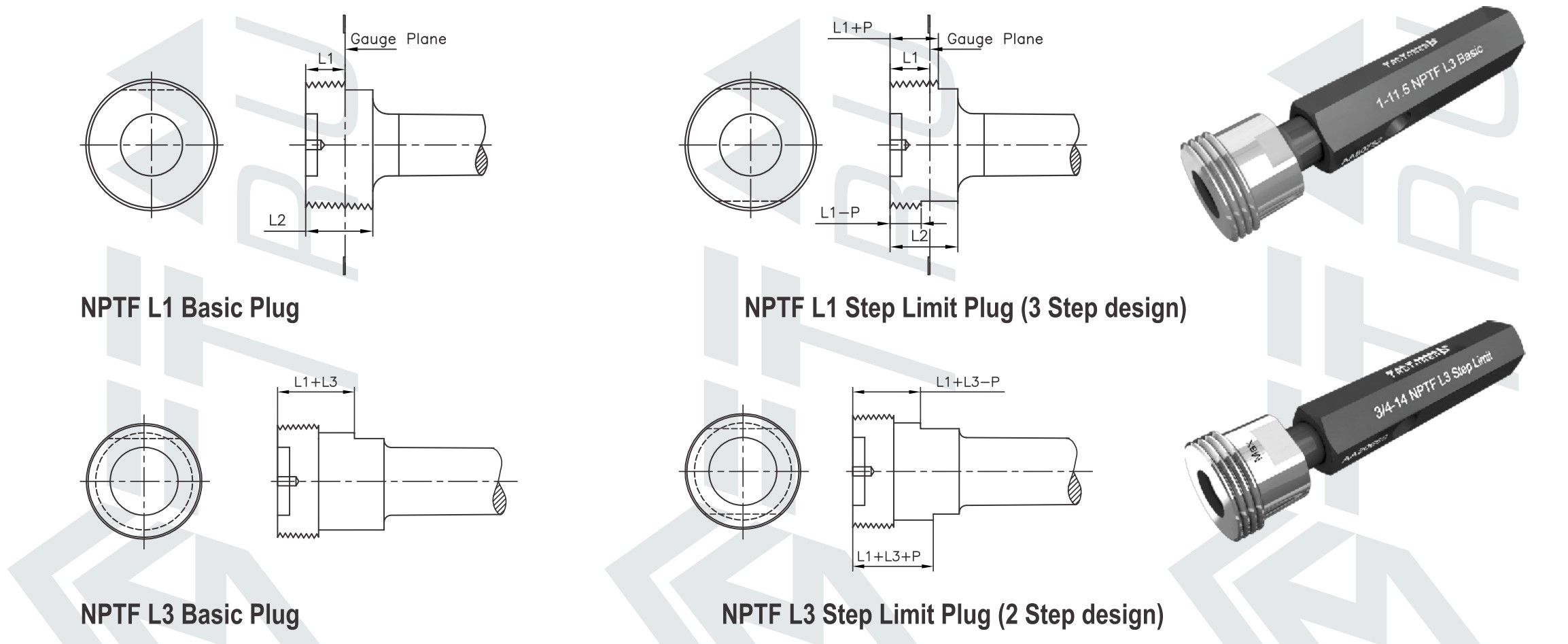

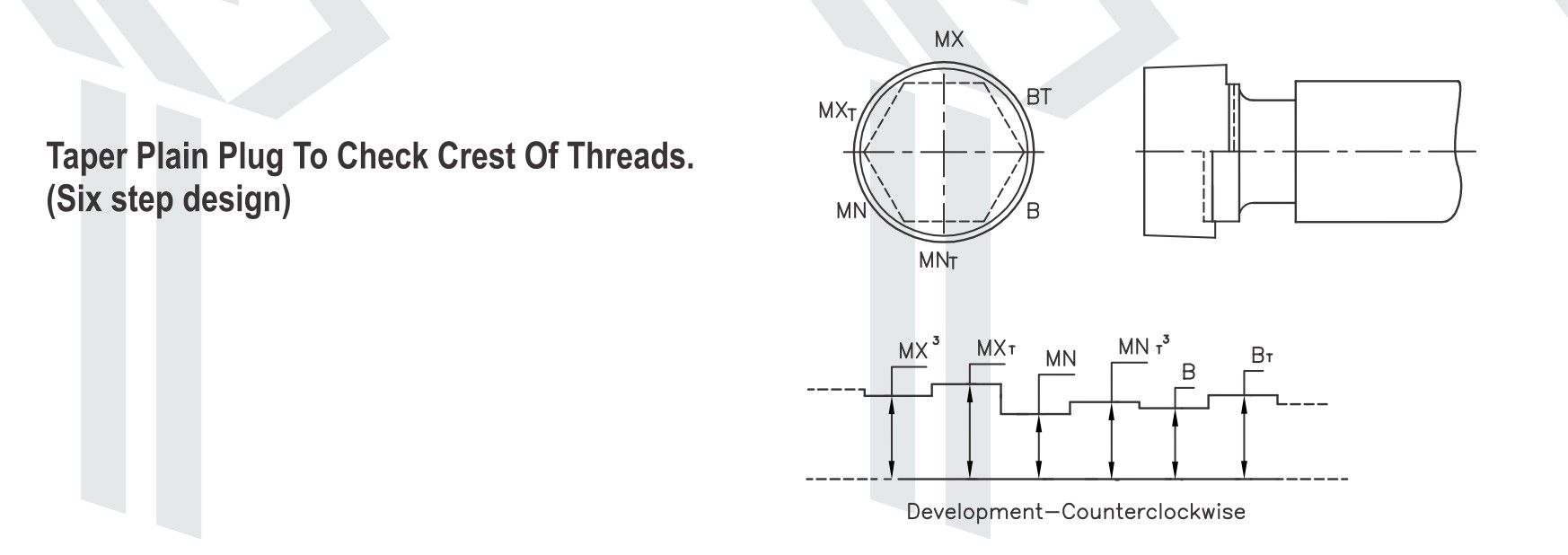

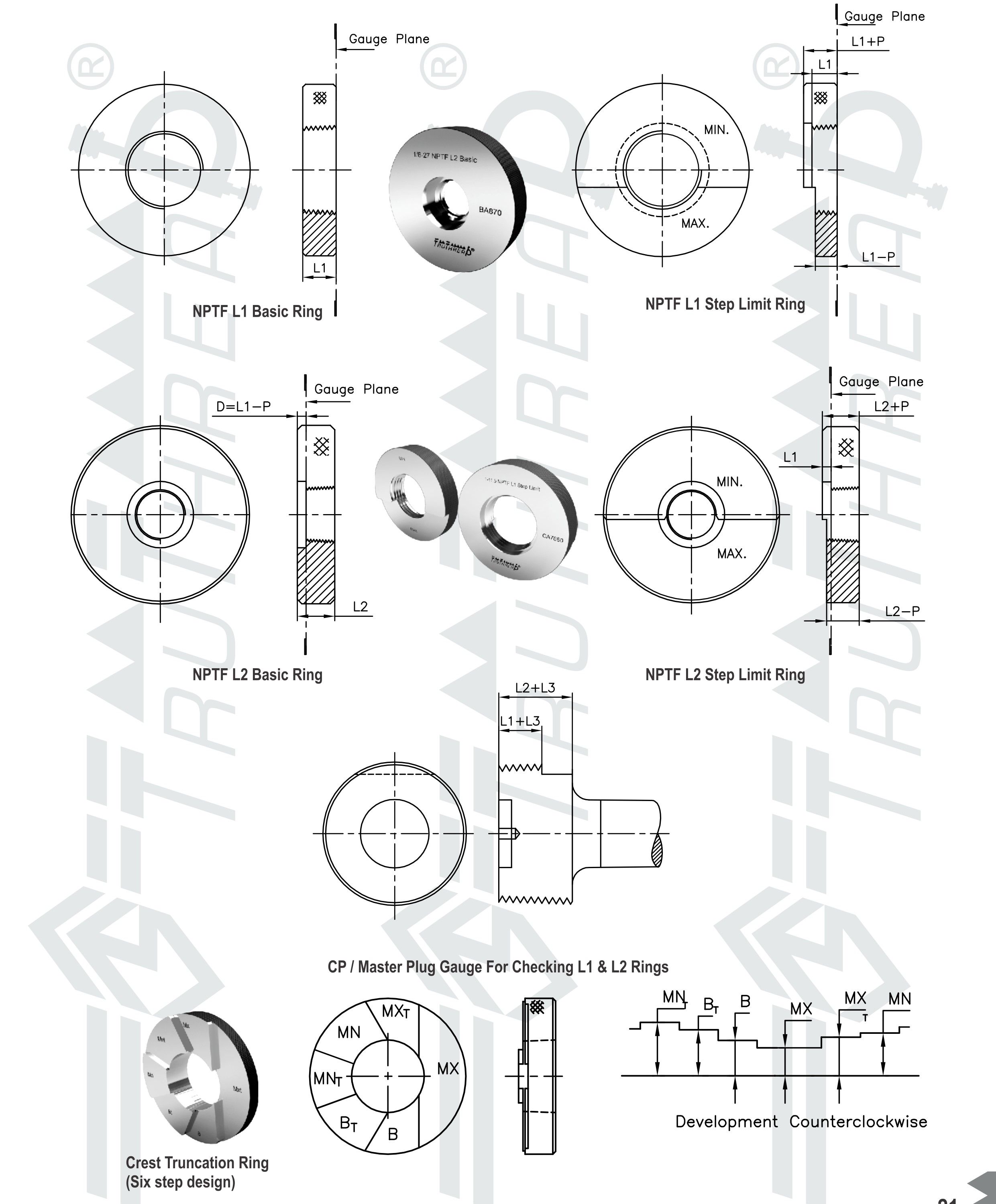

For internal threads (Thread Plug Gauges) two types are recommended L1 - to check effective diameter of thread to hand tightness at the gauge line (large end Dia) L3 - to check effective Dia of remaining thread length (small end Dia) and the taper cone.

For external threads (Thread Ring Gauges) two types are recommended L1 - to check effective diameter of thread to hand tightness at the gauge line (large end Dia) L2 - to check effective Dia of remaining thread length (small end Dia) and the taper cone.

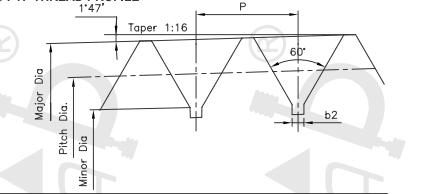

Normally L2 rings and L3 plugs are used in addition to L1 gauges where more stringent examination is required. The use of L2 and L3 gauges is only effective when the designer full thread length in the work piece is one thread longer than the nominal thread length. (drg)

Thread gauges NPTF: features of use

NPTF (National Pipe Thread Fuel) is a standard American pipe thread with the property of ensuring the tightness of the connection without the use of a sealing compound.

Developed in the United States, this thread standard has a specific design that gives it the ability to create hermetic connections without the need for additional sealants or sealants. It is also called "dry steel" type due to the absence of petroleum products or other liquids to seal the threaded connection.

The main difference between NPT (National Pipe Thread) and NPTF is the shape and construction of the thread. NPTF has an additional conical cutter, which allows you to create tight hermetic connections when using sealing gaskets. This makes NPTF ideal for applications where it is important to avoid leaks, especially in systems involving the transportation of fuel and other combustible substances. The main advantage is that NPTF helps prevent leaks and ensures joint reliability without the additional use of sealants, making it an important standard in the fuel transportation and gas storage industry.

Thread gauges PTF: features of use

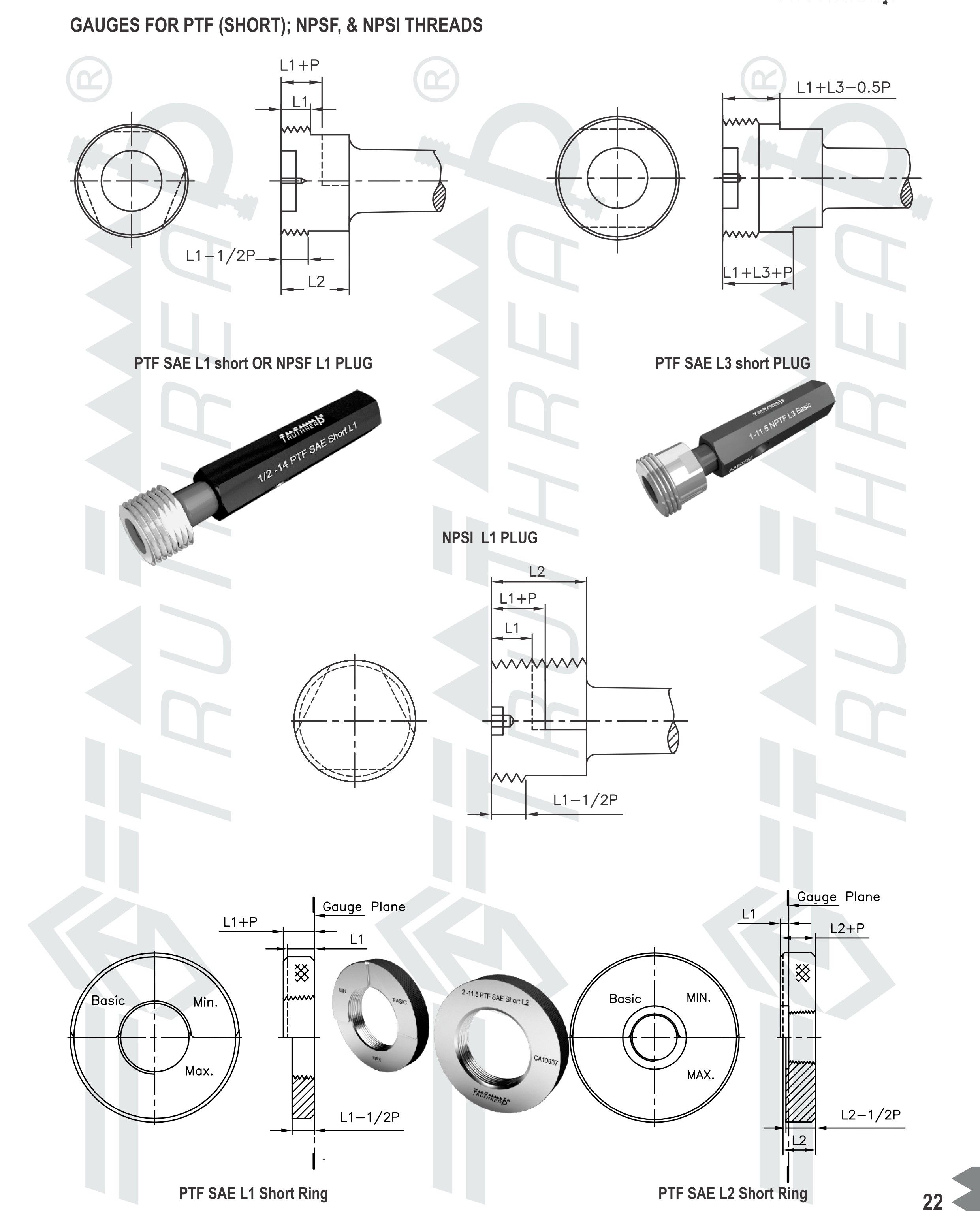

PTF (Pipe Thread Form) are short gauges (with less thickness) and are used for similar applications as NPTF. They help determine the size and shape of the thread on the external and internal surfaces of pipes and fittings, where reliability and tightness of the connection are required. This makes them ideal for measuring and inspecting threads on piping parts where access is limited or gauge penetration depth is limited. We manufacture PTF gauges as well as NPSF gauges and NPSI gauges.

PTF gauges are used to determine the size and shape of threads on both the external and internal surfaces of pipes, fittings and piping system components. The main purpose of using PTF gauges is to verify that threaded connections meet standards and specifications and to ensure the correct thread shape and size. This is important to ensure the reliability and tightness of connections in pipeline systems.

In general, PTF gauges, like NPTF, play an important role in the field of installation and maintenance of pipeline systems, ensuring accuracy and safety in their work.