API Gauges for the Oil and Gas Industry: For Pipeline, Casing and Tubing

Casing, Tubing and Line pipe threads developed by the American Petroleum Institute (API) play an important role in the oil and gas industry. These gauges are designed to control and measure the threads of oil and gas pipes used in drilling rigs and pipeline systems for the transportation of hydrocarbons.

API, as the global leader in standardization for the oil and gas industry, develops and sets quality and safety standards for these critical connections. Thread gauges play a key role in ensuring proper operation of casing wells and pipeline systems.

Technical characteristics of API gauges for the oil industry

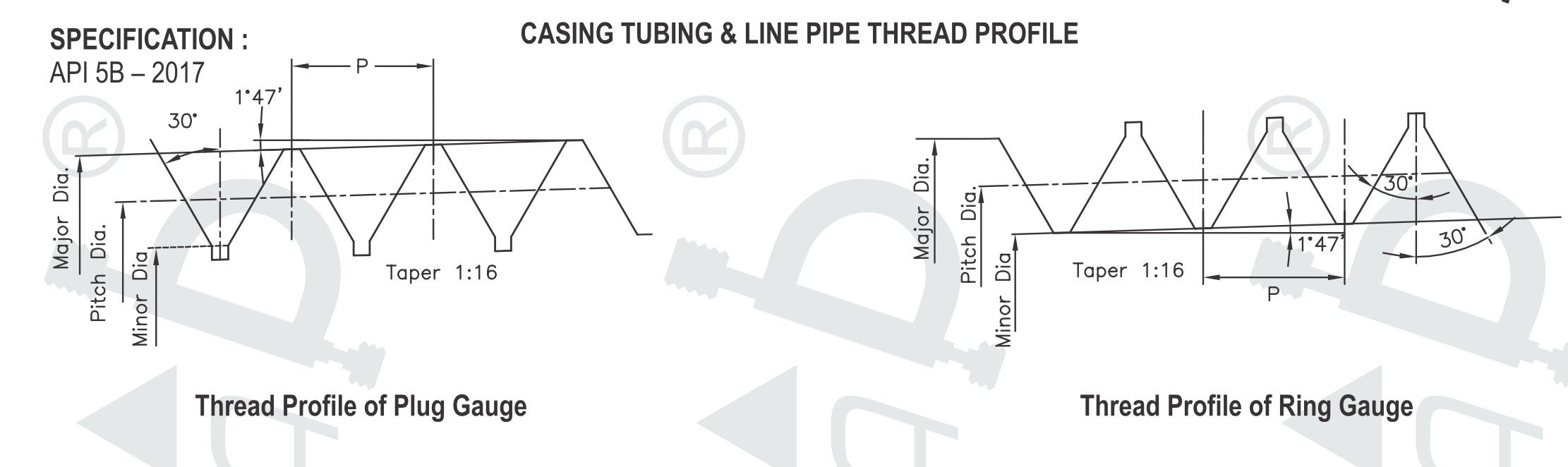

Casing & Tubing Line Pipe Thread Profile

Specification: API 5B - 2017

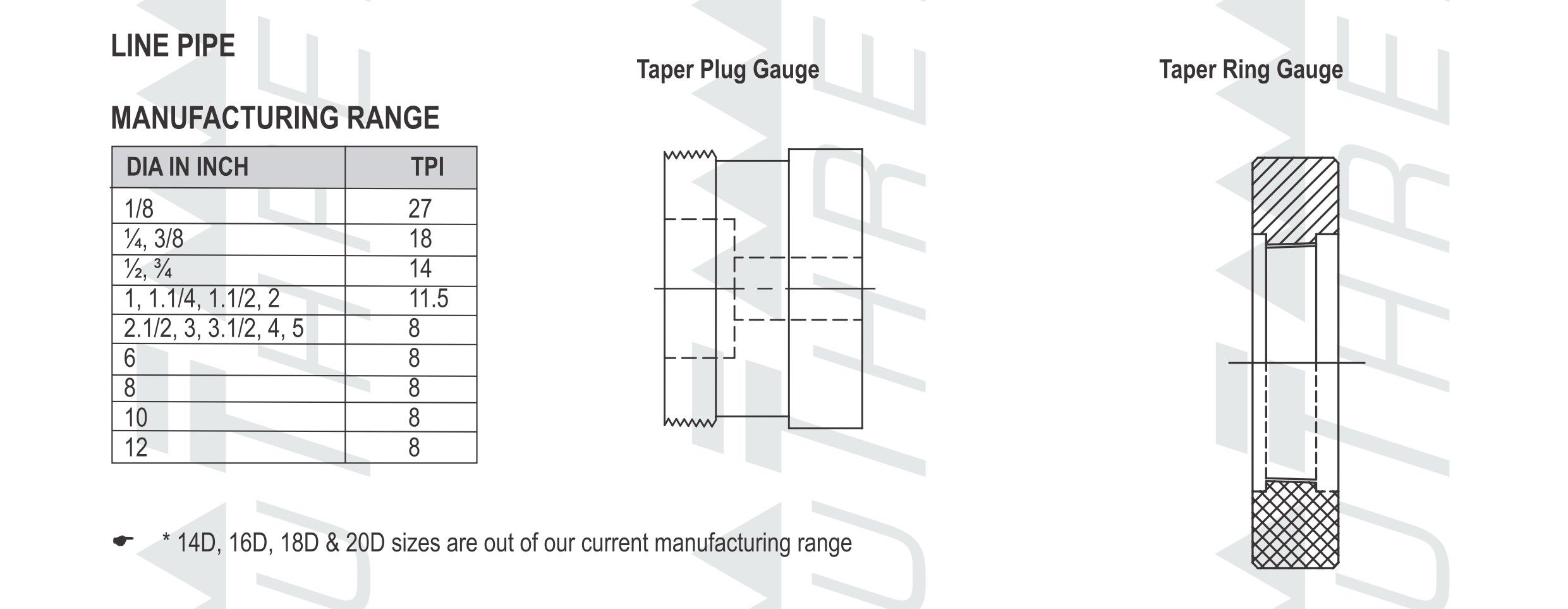

LINE PIPE

TruThread Manufacturing Range

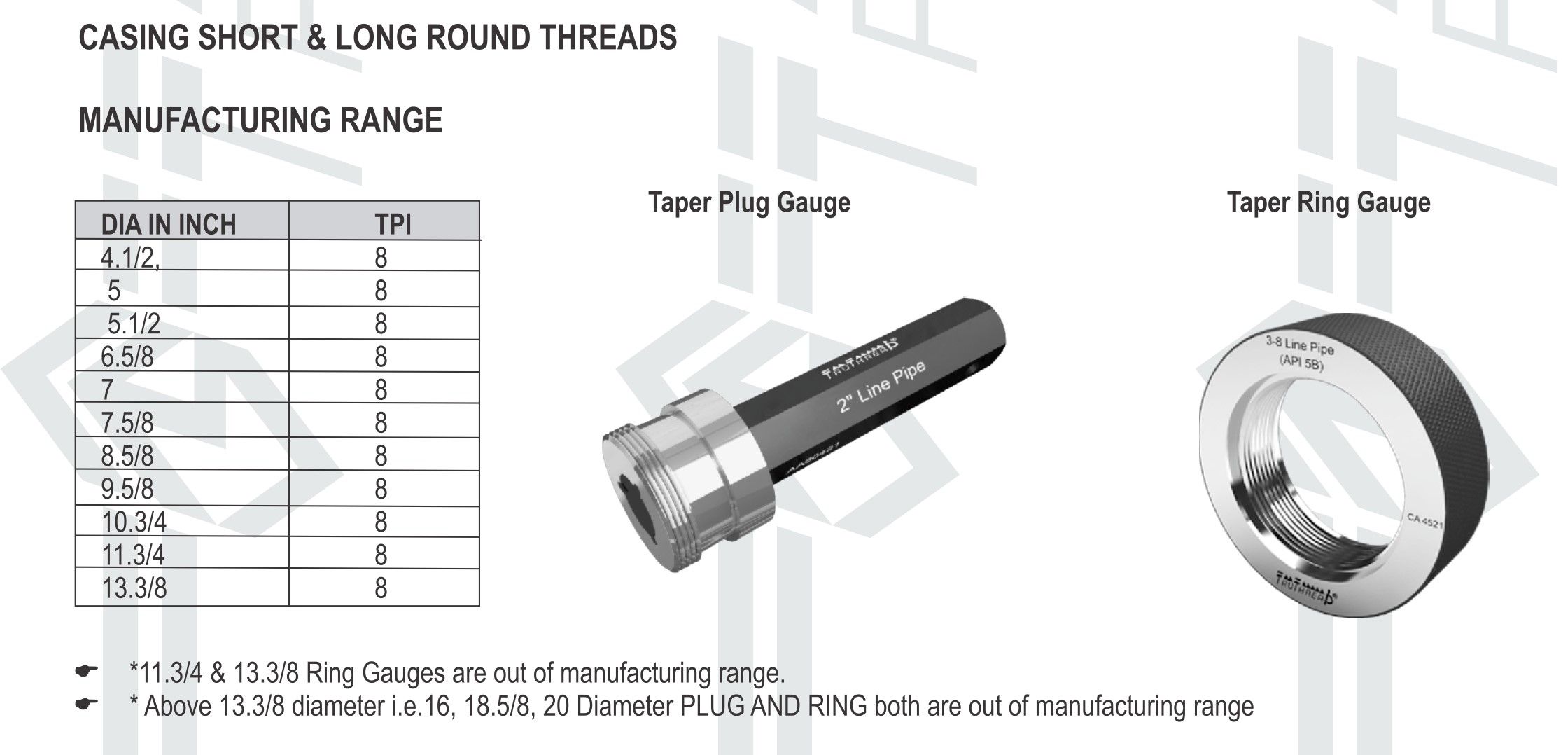

Casing Short & Long Round Threads

TruThread Manufacturing Range

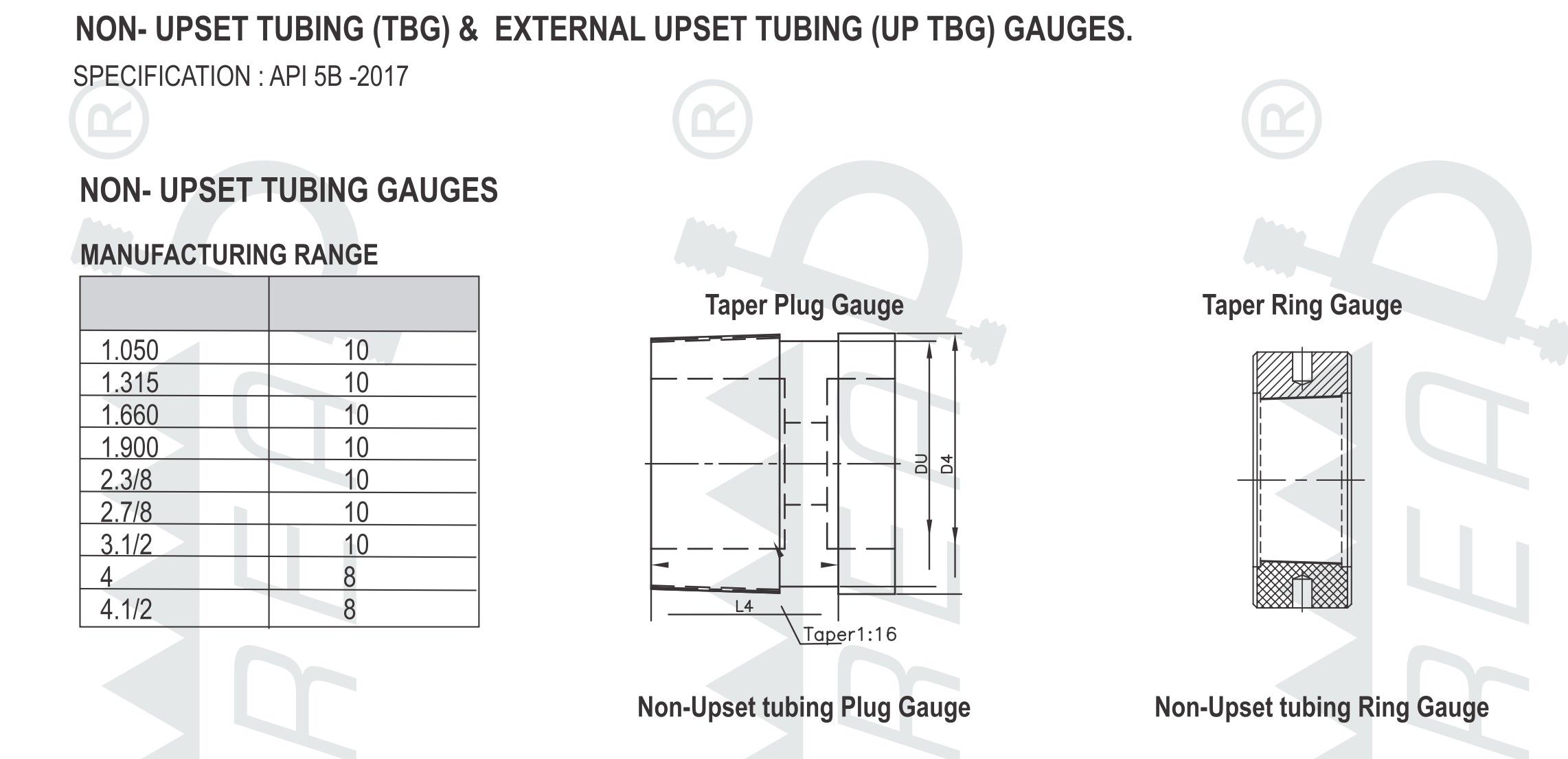

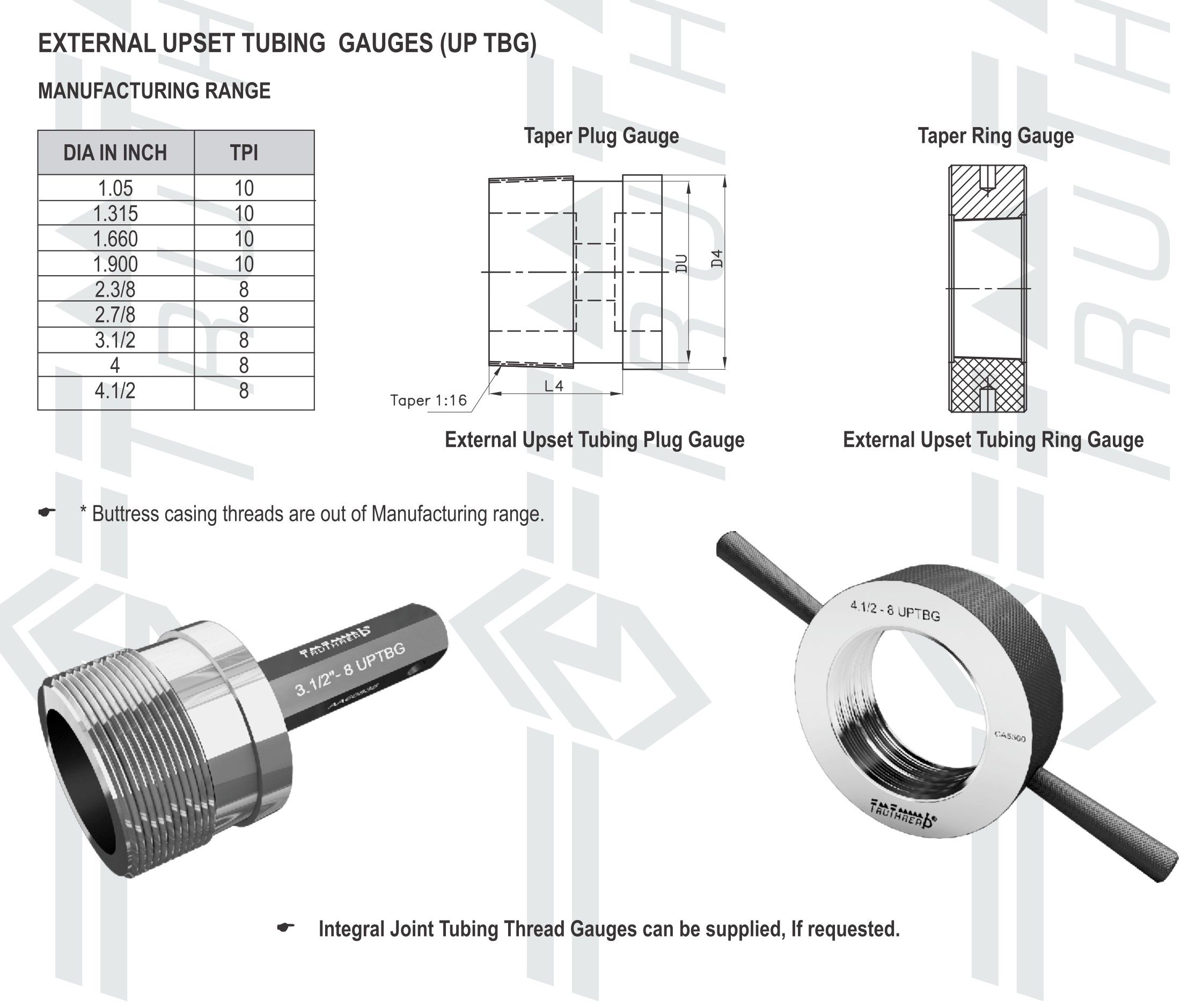

Non-Upset Tubing (TBG) & External Upset Tubing (UP TBG) Gauges

Specification: API 5B - 2017

Non-Upset Tubing Gauges

External Upset Tubing Gauges (UP TBG)

Integral Joint Tubing Thread Gauges can be supplied, if requested

Use of gauges for the oil industry

Gauges developed by the American Petroleum Institute (API) are important tools in the oil and gas industry. They are used to control the threads and diameters of pipelines used in oil rigs, pipelines and other parts of oil and gas equipment. The main applications of these gauges include:

Casing Threads: Casing thread gauges are used to inspect and inspect oil and gas well casing threads. They help ensure proper connection and tightness in casing wells.

Tubing Threads: Casing thread gauges are also used to thread tubing used for oil and gas production and transportation. They help to guarantee a reliable and hermetic connection.

Line Pipe Threads: Line pipe thread gauges are used to ensure the accuracy and standard of threaded connections in pipeline systems for the transportation of oil and gas.

API has developed a number of standards and specifications for threaded connections and equipment used in the oil and gas industry. The gauges meet these standards and allow manufacturers and operators of oil and gas equipment to check and maintain the quality and tightness of joints, which is critical to the safety and efficiency of production and transportation of energy carriers.

Using these gauges helps ensure that threaded connections meet API requirements for quality, tightness, and durability. This provides an important advantage in ensuring the safety and efficiency of oil and gas operations, ensuring the reliability of production and transportation systems.

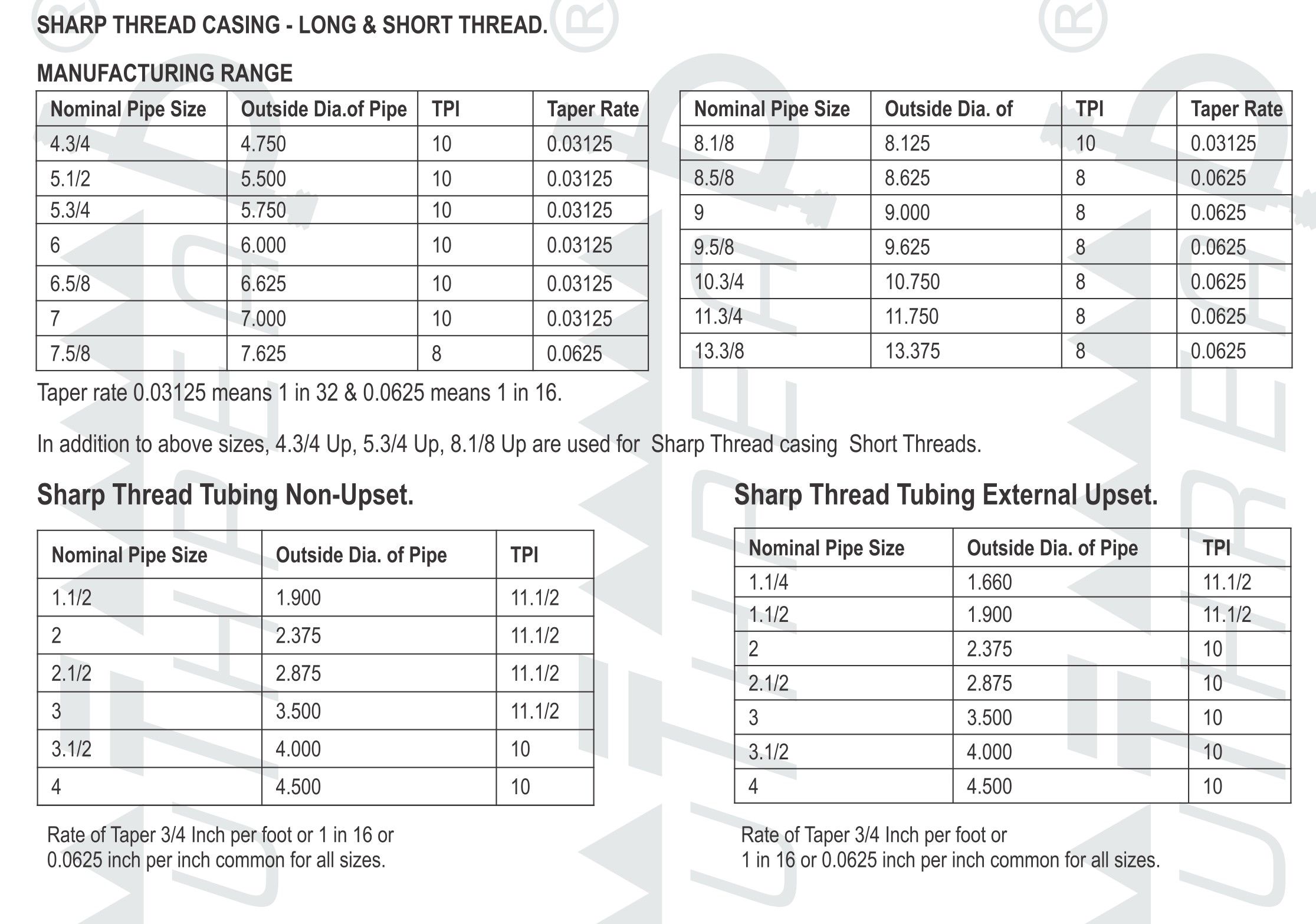

Gauges for measuring sharp thread connections in the oil industry

Sharp Threads Casing & Tubing Gauges are an essential tool in the oil and gas industry for inspecting and measuring sharp threaded connections used in wellbores and production systems.

Technical characteristics of Sharp Threads gauges

Specification: API 5A - 1994 This is an old API standard now obsolete, we have still covered it as still in some cases gauges for these are required.

Sharp Thread Casing - Long & Short Thread

TruThread Manufacturing Range

Use of Sharp Threads gauges for the oil industry

Sharp Threads gauges are designed to test and control the accuracy of thread connections, ensuring compliance with the standards and specifications set by the oil and gas industry.

Sharp threads allow for hermetic connections, which is critical for preventing the leakage of liquids and gases in wells and production systems. They help to check the strength of threaded connections, which is an important aspect in the harsh conditions of drilling and mining.

Sharp Threads gauges meet the standards and specifications defined by the American Petroleum Institute (API), which sets standards for equipment and technology in the oil and gas industry.

Overall, Sharp Threads Casing & Tubing gauges play an important role in ensuring the quality, safety and reliability of threaded connections in the harsh operating conditions typical of these industries.

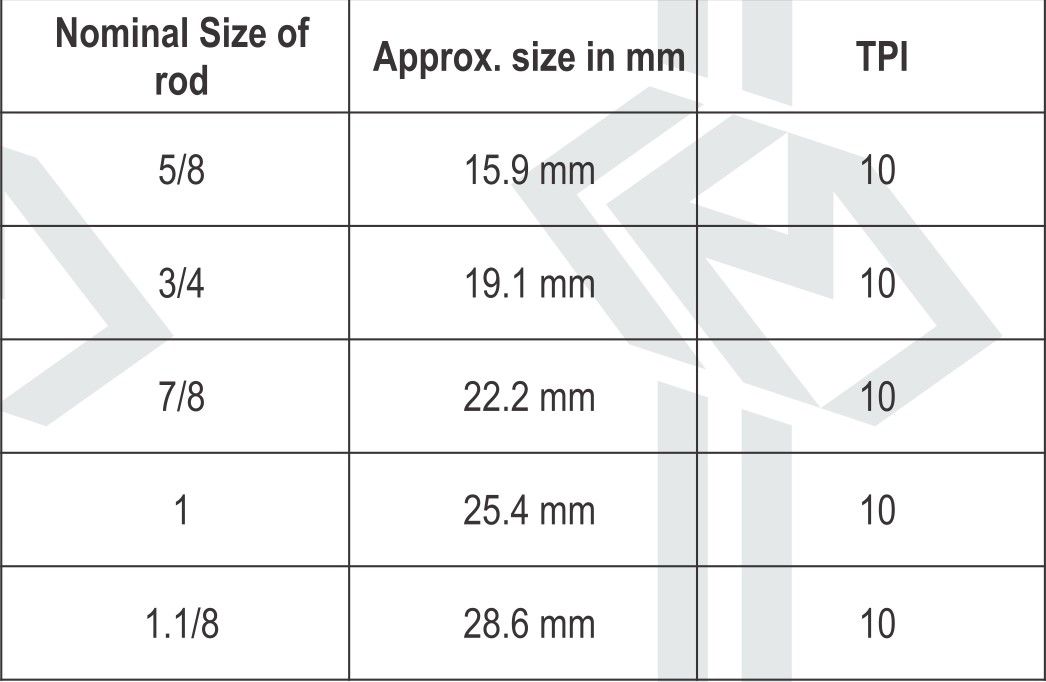

Gauges for sucker rods in the oil industry

Gauges for sucker rods are of great importance in the oil and gas industry. They are designed to control and measure thread connections, which play a critical role in ensuring a correct and reliable connection. Thanks to the sharp thread connections on the sucker rods, it is possible to create hermetic connections, which is extremely important in order to prevent the leakage of liquids and gases in wells and production systems.

Technical characteristics of gauges for sucker rods

Specification: API II AX - 2015 & II B - 2015

The main characteristics of these gauges include thread accuracy, strength and reliability of thread connections. It is important to note that these gauges meet the standards and specifications set by relevant organizations such as the American Petroleum Institute (API). This ensures quality compliance and ensures safety during oil and gas production.

Specification for Subsurface Rod Pump assemblies, Components and Fittings.

We manufacture Thread gauges to check external threads of polished rod pin & internal threads of Box connections.

Use of gauges for sucker rods in the oil industry

Gauges for pump rods are made of high-quality materials and have a long service life. They are regularly inspected and serviced to ensure their accuracy and reliability over a long period of operation.

They are an integral part of the oil and gas industry. They are used to control and measure threaded connections, which is important to ensure the correct operation of the oil and gas production system from the well. Since the safety and efficiency of mining depends on these connections, the accuracy and reliability of gauges play a critical role.

These thread gauges are used to check both external and internal threaded connections on pump rods and box joints. They allow you to determine the compliance of threaded connections with standards and specifications, ensuring reliability and safety in the mining process.

Pump rod gauges play a key role in ensuring the quality, safety and efficiency of the oil and gas production process in the oil and gas industry. They determine the accuracy of threaded connections and help avoid possible leaks and accidents.

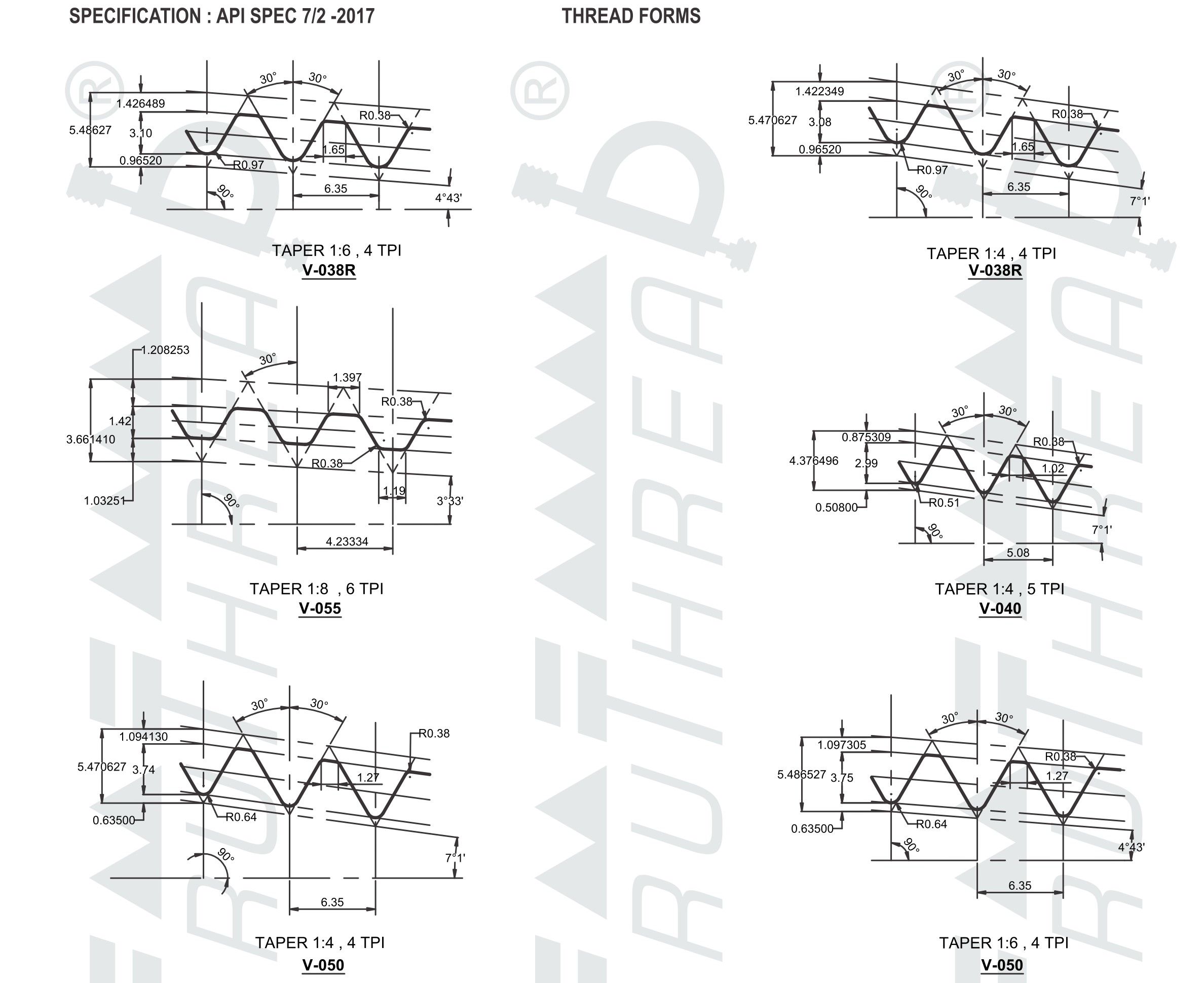

Gauges for thread connections Rotary Drill Stem Elements

The oil industry is characterized by a constant need for high accuracy and reliability in the processes of extraction and processing of raw materials. In this context, measuring gauges designed for the control of threaded connections on the details of boreholes are of great importance.

These special gauges are used to objectively check and confirm the correctness of thread connections on rotary parts, rods and other components of drilling equipment. They provide high accuracy and reliability of measurements, which is very important for achieving optimal efficiency and safety in the operation of oil and gas wells.

These gauges are becoming an integral part of the process of quality control and ensuring the correctness of connections carried out by oil companies. Their contribution is to maintain the stability and reliability of the equipment, reduce the risks of accidents, and, as a result, ensure uninterrupted and safe work in the field of oil and gas production and processing.

Technical characteristics of gauges for rotary drill in the oil industry

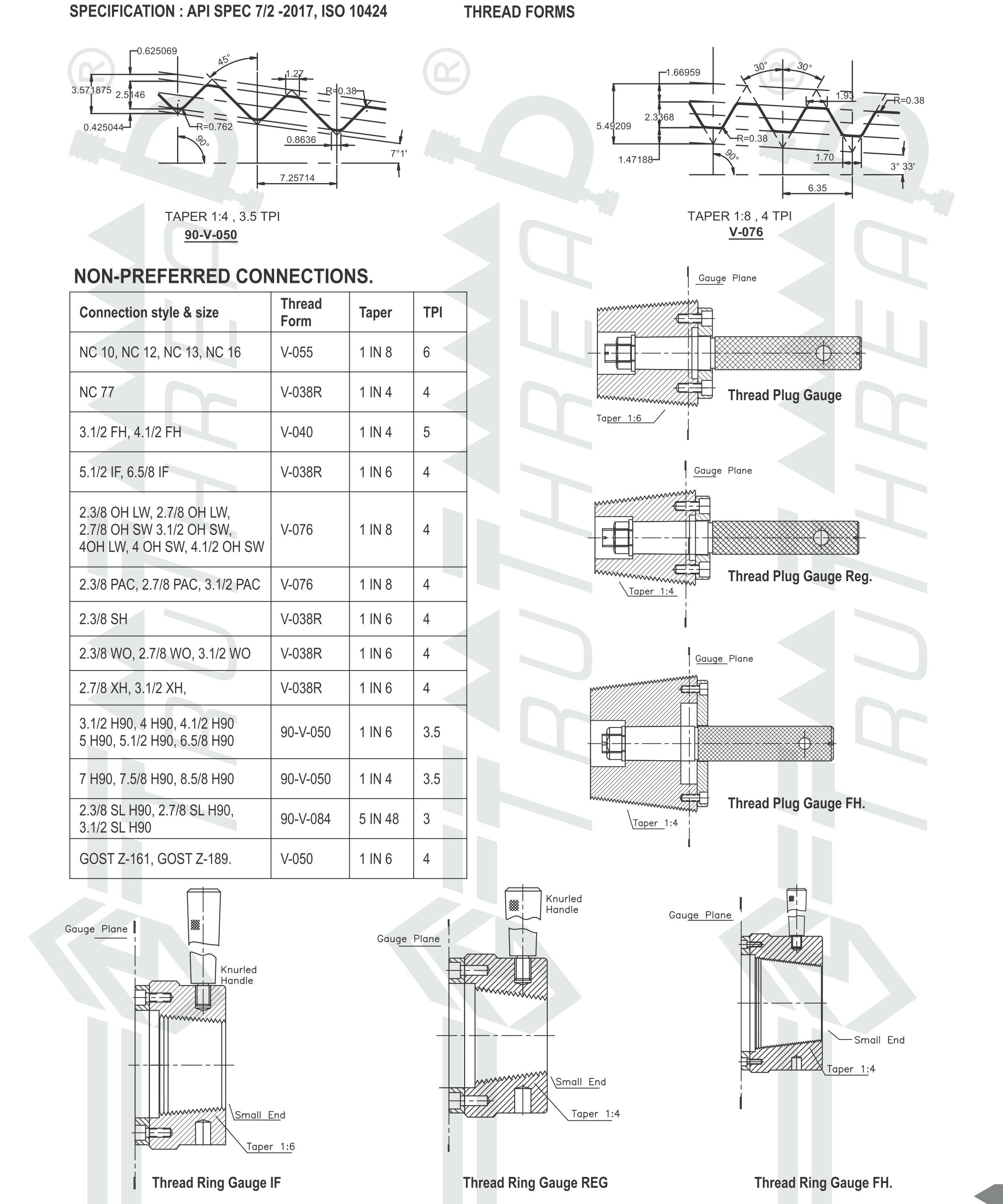

Specification: API SPEC 7/2 - 2017

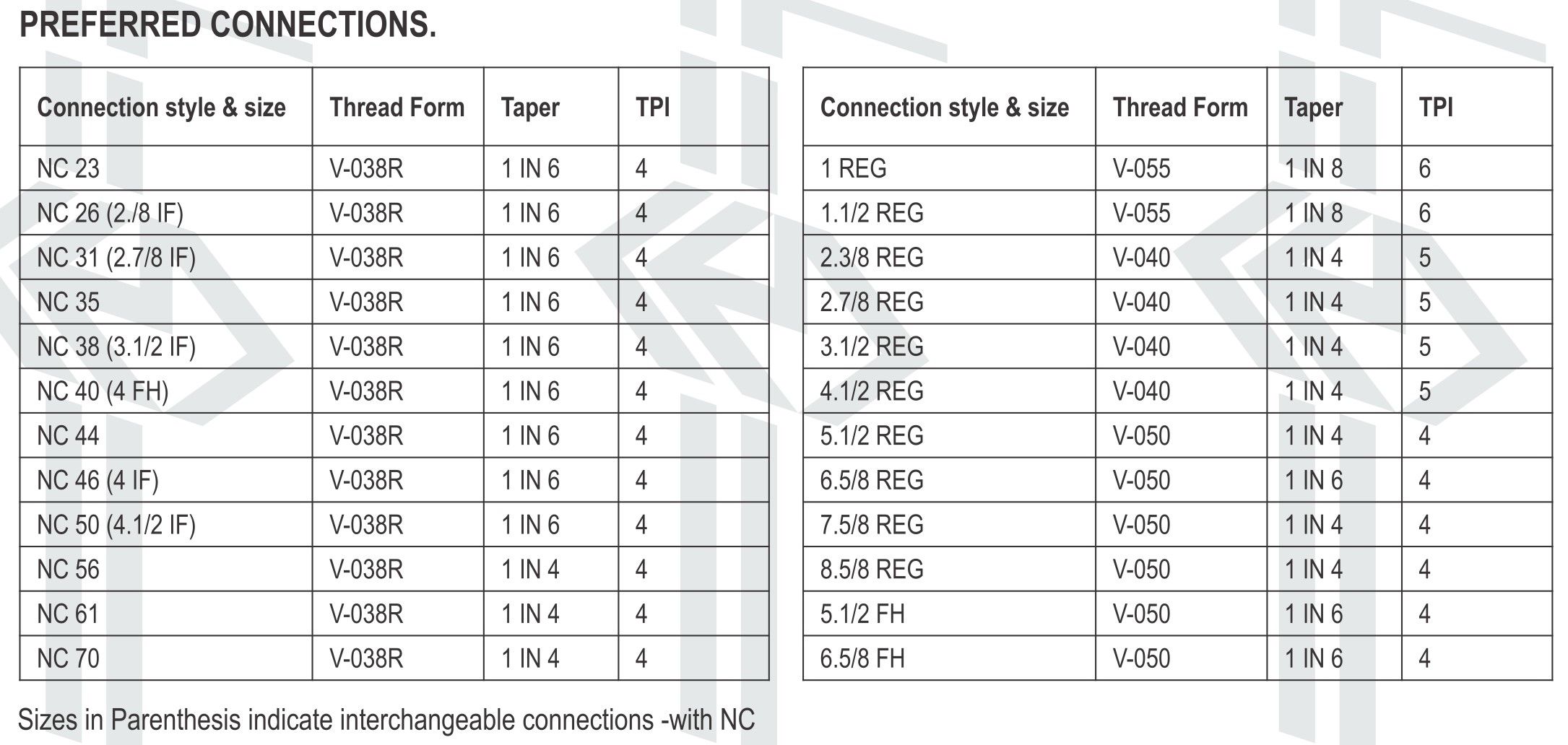

Preferred connections

Preferred connections

The technical characteristics of the gauges meet high standards of quality and accuracy. Compliant with API SPEC 7/2 - 2017, these gauges are designed to ensure that threaded connections meet the highest standards and specifications for well drilling.

This specification defines the accuracy and parameters of gauges that allow reliable control of threaded connections of oil equipment. They must provide accurate and consistent measurement results to ensure the correct operation of the drilling equipment and ensure the safety of oil and gas production operations.

The specifications of these gauges include parameters such as size, shape and strength that allow them to accurately check and confirm the correctness of threaded connections in well drilling. These characteristics play an important role in ensuring the efficiency and safety of oil and gas operations.

Using gauges for rotary drilling

The main application of these important measuring gauges is the inspection and control of threaded connections used in rotary shoulder joints, rods and components of boreholes. In the context of the oil and gas industry, these joints are at the heart of the entire oil and gas drilling and production process.

Gauges for threaded connections play an undeniably important role in ensuring the correct operation and reliability of these connections. They help determine whether threaded connections meet standards and specifications, ensuring a high level of safety and reliability in extreme drilling and production environments. The accuracy and reliability of these gauges are important to prevent potential accidents and ensure optimal performance, making them a crucial tool for the oil and gas industry.