PG gauges for safe installation of conduit pipes

PG gauges are special measuring tools used to check the thread size on conduits used for electrical wiring. These measuring devices play an important role in ensuring the accuracy and reliability of electrical systems, since the correct thread size allows for tightness and efficient connection of pipes.

One of the key applications of PG gauges is the inspection of threads on conduits. Conduits are special pipes used to protect electrical wires and cables from external factors such as moisture and physical damage. Thanks to the threads on the conduits, a reliable connection and sealing are possible, which are important factors in any electrical system.

PG gauges for pipelines: technical characteristics and application

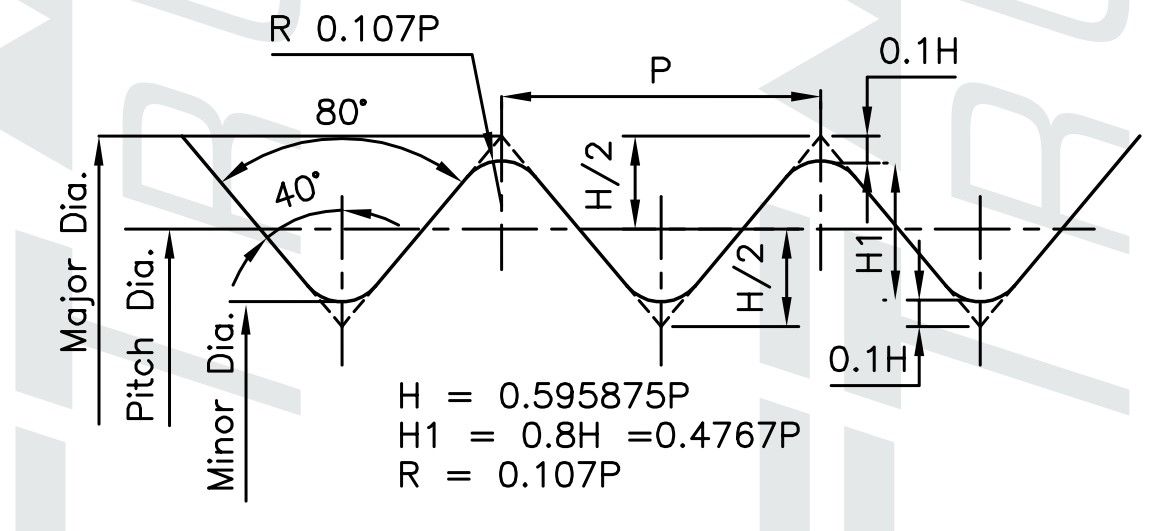

Specifications: Basic dimensions: DIN 40430 - 1971. Measuring practice: DIN 40430 (1) - 1970 & DIN 40430 (2) - 1972

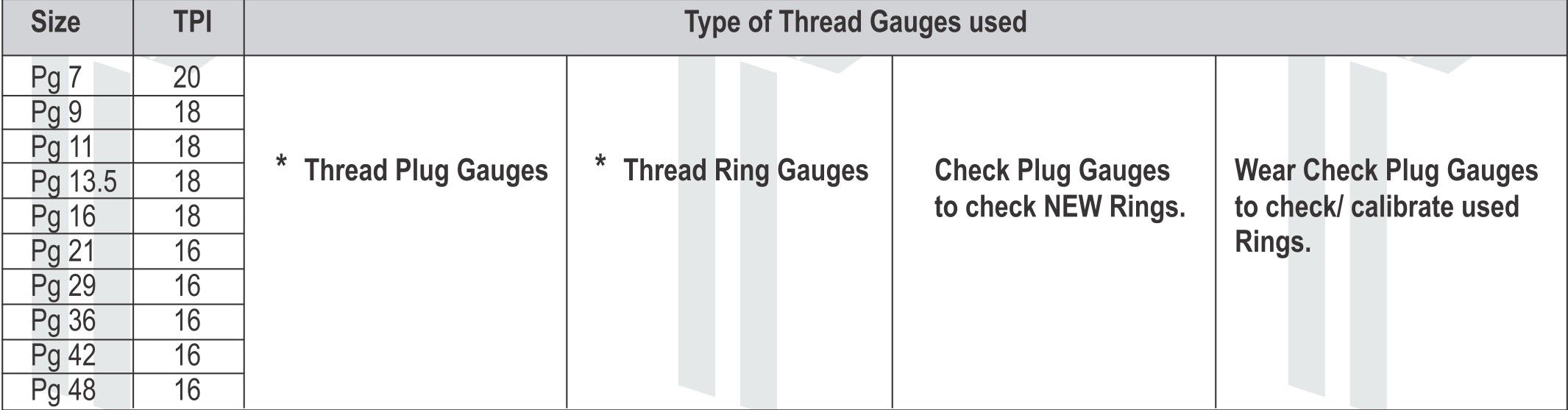

Manufacturer's range

The use of PG gauges helps to check the correctness of the threads on the conduits, ensuring that they meet the standards and requirements. This is important to prevent possible leaks, short circuits and other problems that can occur due to improper connection of conduits.

In the production, installation and maintenance of electrical systems, PG gauges become an indispensable tool for ensuring quality and safety. They help specialists to accurately determine the thread diameter and depth, which are important parameters for the correct connection of the conduit with other elements of the electrical system.

PG gauges GO&NOGO for steel pipelines

Specifications recommends threaded GO & plain NoGo gauge plugs and rings PG

Designed specifically for thin-walled steel pipelines, GO and NOGO play an important role in ensuring the quality and reliability of a threaded connection. With these tools, you can ensure that the thread size meets the established standards.

The GO Thread Gauge is used to ensure that the maximum material condition of the thread is achieved. This ensures the reliability and durability of the thread connection.

The NOGO Plain Gauge is used to check the smaller diameter or top of a thread. It serves to determine whether the threaded connection meets the established standards and requirements.

It is important to note that these gauges are manufactured with high precision to the highest specifications. This guarantees their long service life and reliability in use, contributing to the quality and safety of thin-walled steel pipelines.