Plain gauges from the manufacturer TruThread Europe

Plain gauges are used for attribute inspection of internal and external diameters of products. They are indispensable assistants in various industries, ensuring high accuracy and reliability of measurements. Plain gauges are used in quality control processes to ensure that manufactured parts meet specified standards and have the correct diameters.

In addition, Plain gauges also have additional advantages. They allow you to quickly and conveniently measure the diameters of products, which is very important in the conditions of industrial production.

TruThread Europe's range includes Plain plug gauges, Plain ring gauges and Setting rings.

Plain plug gauges: applications and characteristics

Plain plug gauges are used in many industries where measurement accuracy and reliability are critical factors. They are used to check the internal diameters of products to ensure high measurement accuracy and quality control in various industries, including mechanical engineering, automotive, aerospace and many others.

Specification: ISO 286, ISO 1938/DIN 2245, DIN 7150 Basic dimensions: ISO 286 Part 1 & 2-2010 / IS 919 Part 1 & 2-2014 Gauging Practice: DIN 7164 - 2017 & IS 3455-1971, IS 7859-1975

Tolerance classes: ISO/DIN, such as H8, G7, D5 and JS, etc. It is also possible to manufacture special tolerances specified by customers, such as Dia. 35.000+0.150 mm OR Dia. 20.000+0.1/-0.050 mm

Material: hardened and stabilized steel AISI 01 / EN-31 (SAE 52100) with a hardness of 60-62 HRc.

Our company offers the production of a wide range of gauges. All our products comply with ISO/DIN standards and include different classes of tolerances, which ensure high standardization and compatibility with other tools and equipment.

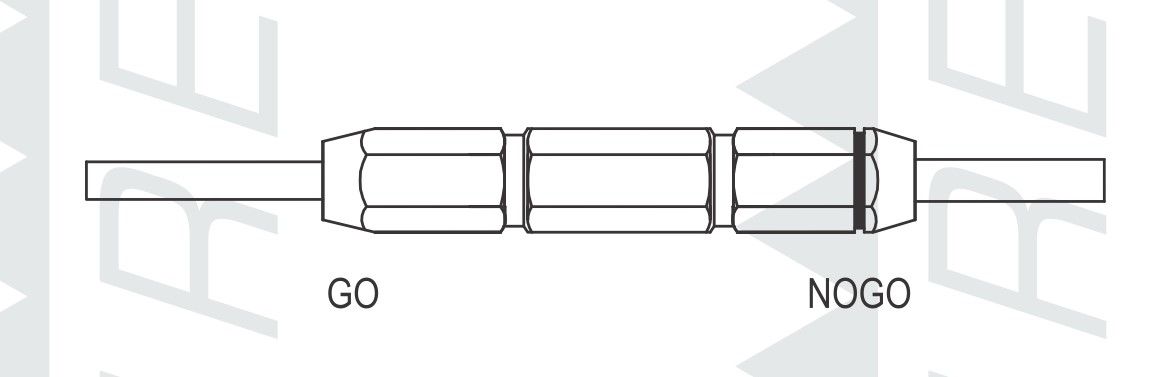

Plain plug gauges up to 5 mm: reversible design

Plain plugs with a reversible design up to 5 mm provide convenience in measuring procedures, allowing measurements in both directions. This simplifies the work process and ensures a faster and more productive measurement.

Specifications: Handle design: ANSI B47.1 OR BS 1044 Part 1 It is made of anodized aluminum with brass collets to hold gauging pin

Our company has the ability to manufacture gauges using a special material - solid tungsten carbide, which is one of the hardest and wear-resistant materials. Such gauges demonstrate high durability and provide reliable and accurate measurement during a long period of operation.

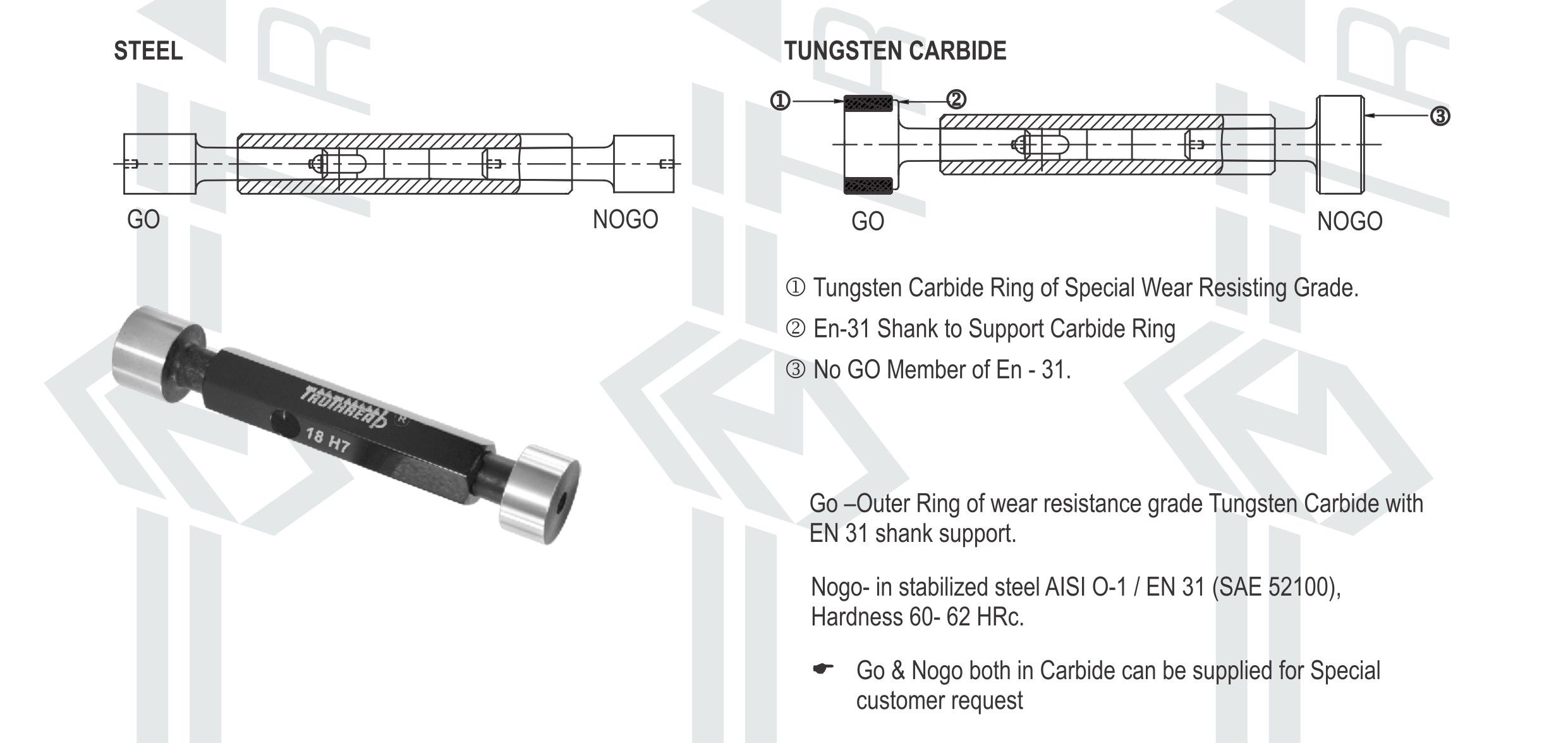

Plain plug gauges 5-65 mm: Taperlock construction

Our plain plug gauges from 5mm to 65mm in diameter with Taperlock design allow you to securely fasten them into the inside diameters of your products.

Specifications: Gauge blanks: ISO 3670-1979 OR IS 613701983 Handle design: ISO 3670-1979 OR IS 5388-1983

It is possible to manufacture gauges from tungsten carbide: GO made of wear-resistant tungsten carbide with EN 31 shank support Nogo made of stabilized steel AISI 0-1 / EN 31 (SAE 52100), hardness 60-62 HRc

We can make Go&Nogo both from carbide according to special customer requests.

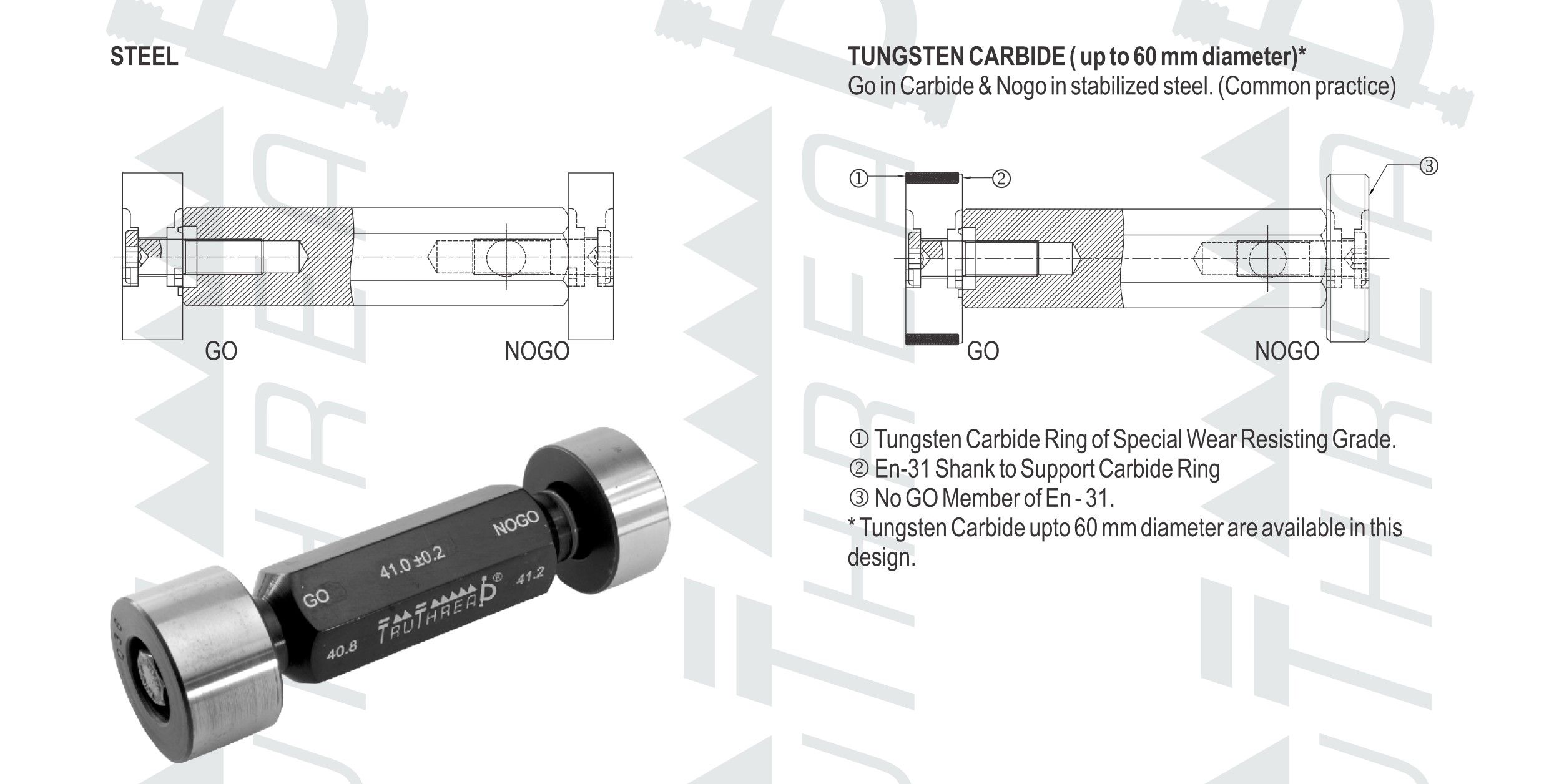

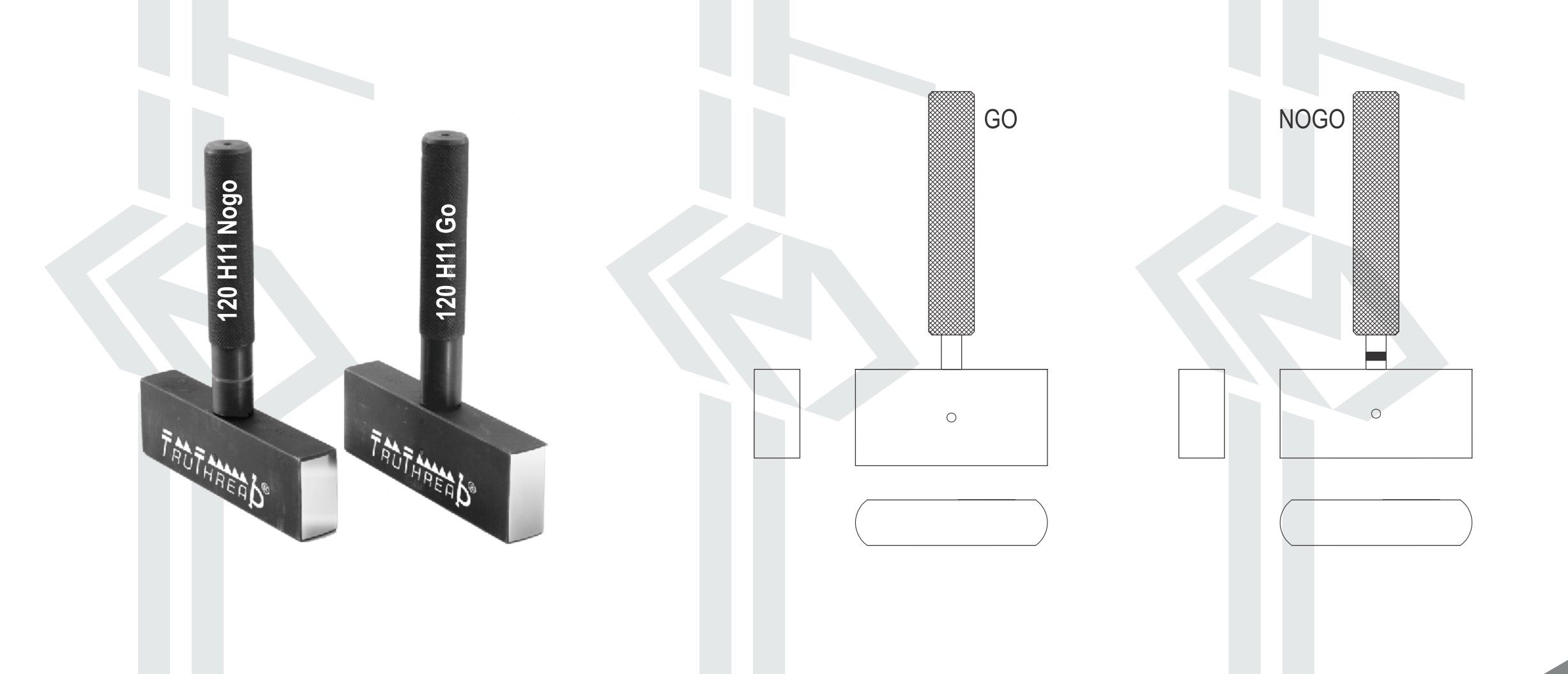

Plain plug gauges above 65mm: Trilock design with single end

Plain plug gauges with a Trilock Single end design with a diameter of over 65 mm securely lock into large internal diameters of products. This design is used for large diameter gauges. In this case, GO and NOGO are placed on separate handles.

Specifications: Gauge blanks: ISO 3670-1979 OR IS 6244-1980 Handle design: ISO 3670-1979 OR IS 5388-1983

Plain plugs from 65 mm are also available in tungsten carbide. GO - from tungsten carbide NOGO - from stabilized steel.

Plain plug gauges from 100 mm to 300 mm can be made like Plate type gauging in Steel. Plug gauges with a steel plate design are easy to use and allow you to measure the diameters of various parts and holes with great ease and efficiency. They are ideal for measuring large diameters, providing accurate and stable results.

Plain ring gauges: applications and characteristics

Plain ring gauges are important tools for measuring the external diameters of various products. They are used in many industries, including mechanical engineering, metalworking, and automotive.

These gauges allow accurate measurement of external diameters. They are essential in quality control processes to verify that manufactured parts meet specified specifications and have the correct diameters.

The assortment of plain ring gauges in our company is very large, we offer a wide selection of sizes and types of gauges that meet different needs and requirements of customers.

Specifications: For Go/Nogo rings Basic dimensions: IS 919 Part 1 & 2 2014 / ISO 286 Part 1 & 2 - 2010 Gauging Practice: IS 3455-1971, IS 7876-1975 & DIN 7163-2017

For Gauging blanks ISO 3670 OR IS 3485-1983 OR DIN 2250-2008 & DIN 2254

Tolerance classes: Our production program covers various tolerance classes defined in ISO/DIN such as h8, h7, d5, js and others.

It is also possible to manufacture plain ring gauges with special tolerances at the customer's request, for example DIA 25.000+0.100 mm or Dia. 12.000 + 0.50 - 0.025.

Material: All ring gauges from TruThread are made of Heat Treatment Hardened & Stabilized Stee AISI 01 / EN 31(SAE 52100), strength 60-62 HRc

We use subzero cooling sustain treatment to ensure dimensional stability of the gauges.

We also allow our customers to order special tolerances that take into account their unique needs and requirements. We understand that some projects may require the use of gauges with special characteristics that are not necessarily considered in the general standards. Therefore, we are ready to work with you on the development and manufacture of gauges that will fully satisfy your needs and help you achieve the best results in your business.

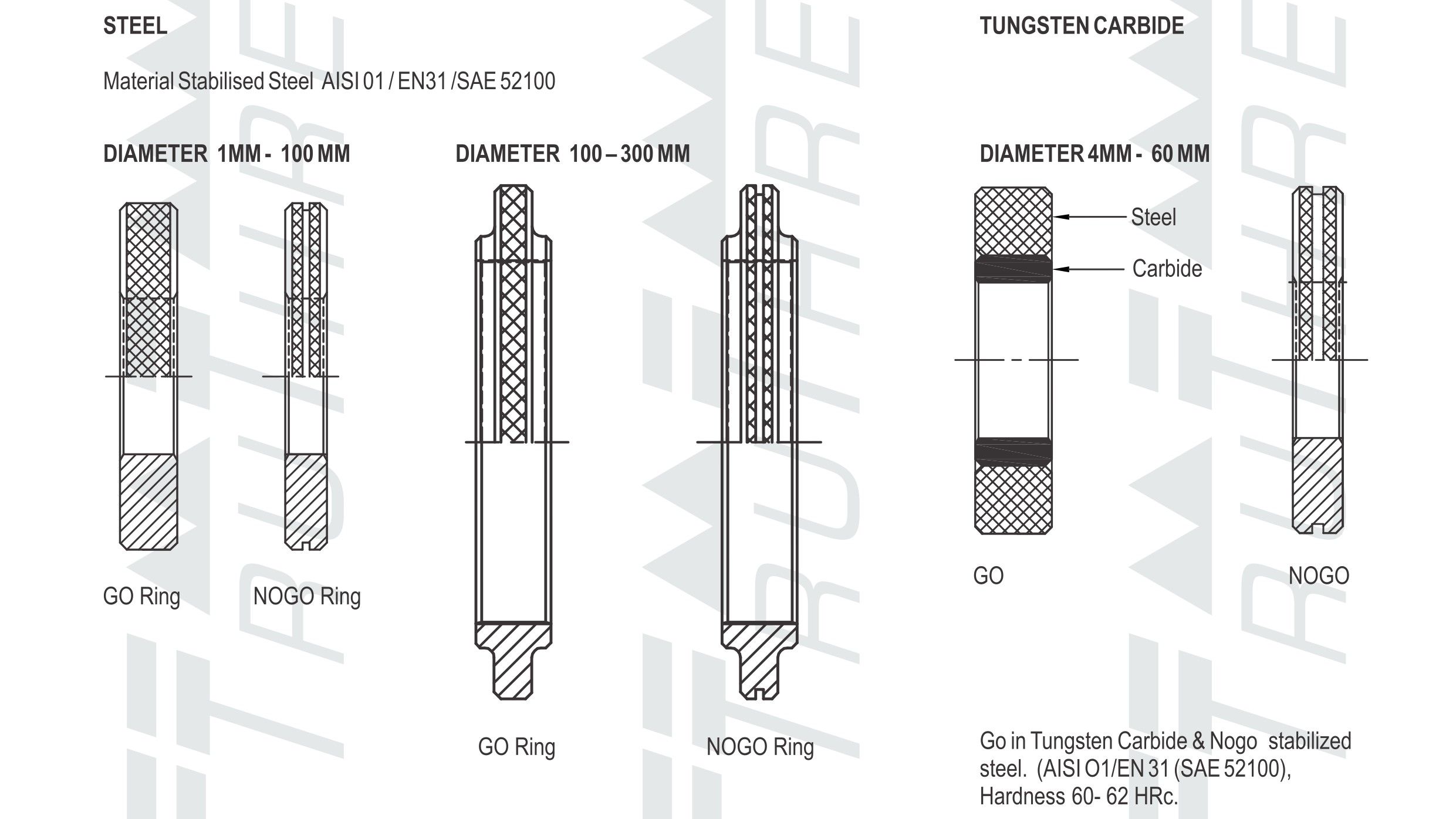

Diameter 1 mm-100 mm | Diameter 100 mm - 300 mm

Our company offers rings made of tungsten carbide, which are available in a diameter range from 4 mm to 60 mm. Our range includes Tungsten Carbide Go-Rings and Stabilized Steel Nogo-Rings. In order to meet the special needs of our customers, we can manufacture Tungsten Carbide Nogo rings on request.

Setting rings: applications and characteristics

Setting ring is a gauge used in industrial production to control and adjust the size and shape of other parts. TruThread's Setting rings are highly precision manufactured because their use depends on ensuring the proper geometric parameters of the products they control.

Setting rings are used as a means of checking manufactured parts for compliance with given standards and specifications. When manufacturing parts, it is important to ensure the correct size and shape so that the finished product is of high quality and able to perform as intended. In this way, the setting rings help to check the parts for defects and determine whether they meet the requirements.

When inspecting parts, workers simply insert the test part into alignment with the setting ring. If the part fits or engages properly with the mounting ring without excessive clearances or overlaps, then this indicates that the part has been manufactured to the required specifications. Otherwise, if the part does not match the snap ring, corrective action is required to achieve the desired performance.

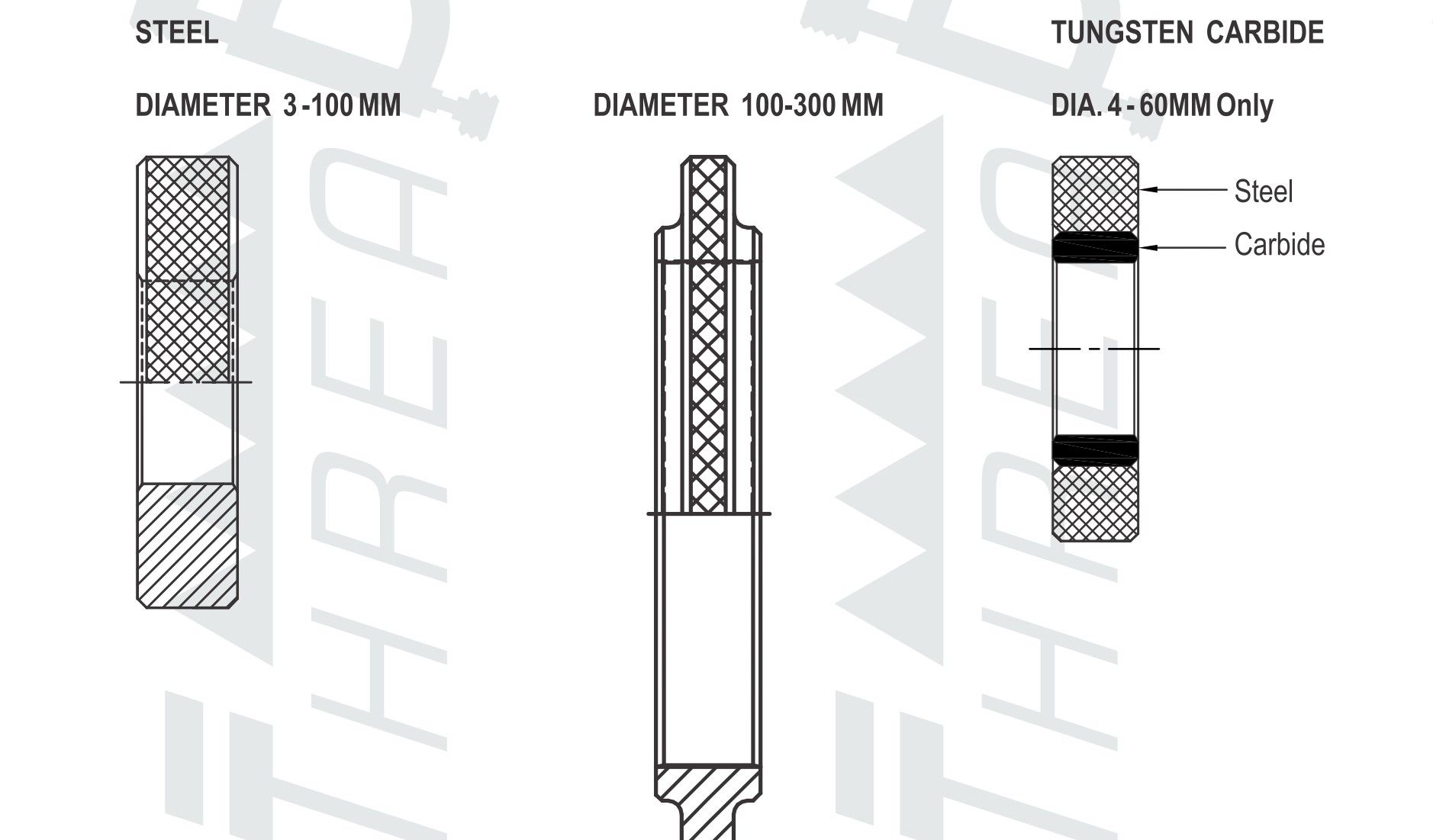

Specification: DIN 2250

Materials: Hardened & Stabilized steel (AISI 01/ EN 31) for rings with a diameter of 3 mm - 300 mm. Tungsten carbide only for rings with a diameter of 4 mm - 60 mm

All steel Setting rings are cryogenically treated to improve their geometric stability. This process involves processing at very low temperatures so that they are less susceptible to deformation or dimensional changes due to external factors, temperature fluctuations or loads. Such rings will remain more stable and reliable in use.

Diameter 3 mm -100 mm | Diameter 100 mm - 300 mm

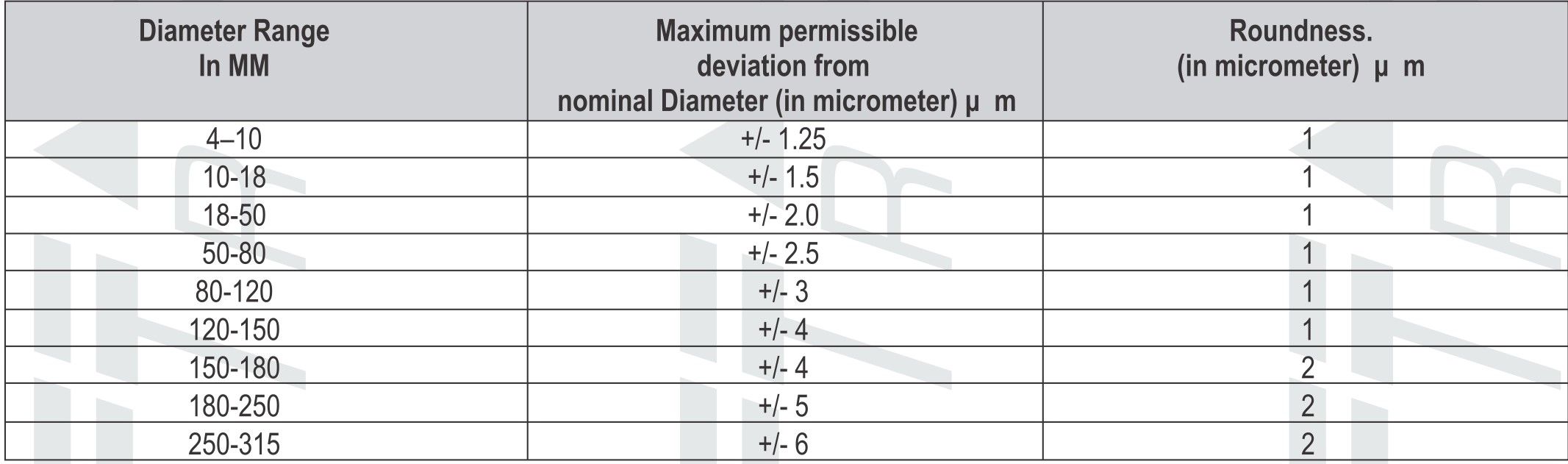

Tolerance for setting rings

Whenever the roundness is within above specified tolerance limit, the actual diameter is marked on the setting ring. The actual diameter shall be within the above specified permissible deviation limit from the specified diameter value.

TruThread Plain Gauges: Essential Quality Control Tools in Industrial Manufacturing

Plain gauges such as plugs, rings, and setting rings are proving to be indispensable tools for quality control in industrial production. They help ensure high accuracy and accuracy of the geometric parameters of the manufactured parts. Plain gauges ensure the reliability and conformity of products to the given standards and specifications, contributing to the creation of high-quality products.

Thanks to the use of plain gauges, production gets the opportunity to effectively control the process of manufacturing parts, avoid production errors and reduce the number of rejected products. These gauges become a reliable support for ensuring a high level of quality and compliance of finished products with the specified standards. In general, plain gauges are an integral part of control and measuring equipment and play a key role in achieving success in the field of industrial production.