R-Pipe Gauges from Manufacturer TruThread Europe

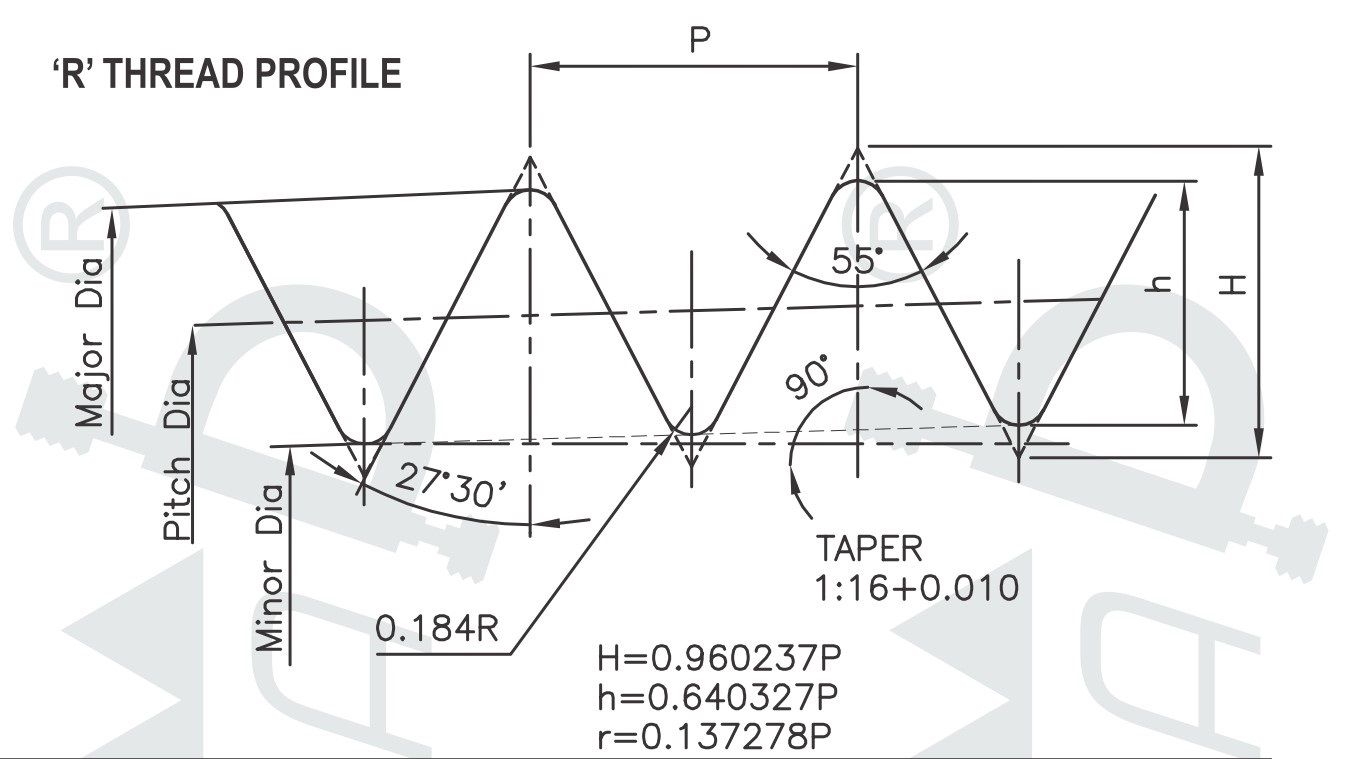

R-Pipe Thread Gauges are high-quality tools designed to provide precision and reliability for pipe connections. They play a crucial role in the process of joining pipe threads, where sealing is demanded. These gauges are intended for measuring and controlling the thread geometry on pipes with various thread types, such as R, Rc, Rp.

Thanks to R-Pipe gauges, high precision of thread dimensions and parameters is achieved, ensuring accurate and sealed connections. This is especially critical when pipeline systems operate under elevated pressure. The use of these gauges helps prevent leaks of liquids or gases through thread connections and ensures the reliable operation of the system.

R-Pipe thread gauges: characteristics and features

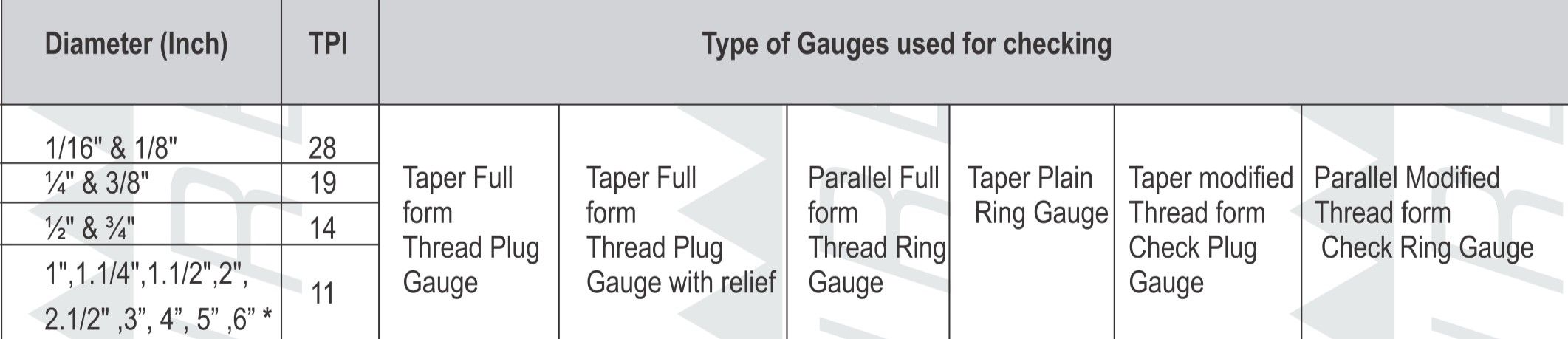

Specification: Basic Dimensions: ISO 7/1 - 1994 / IS 554 - 1999 Gauging Practice: ISO 7/1 - 2000 / IS 8999 - 2003 BS EN 10226-3-2005

Manufacturing range

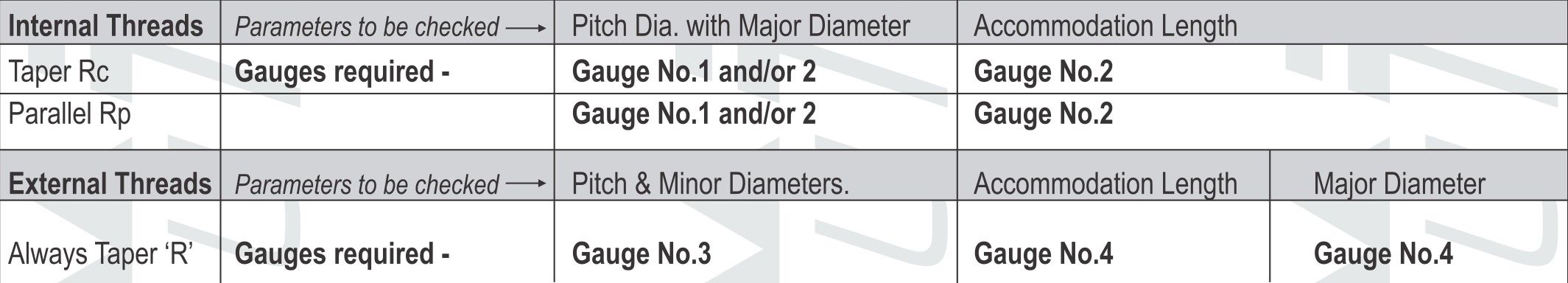

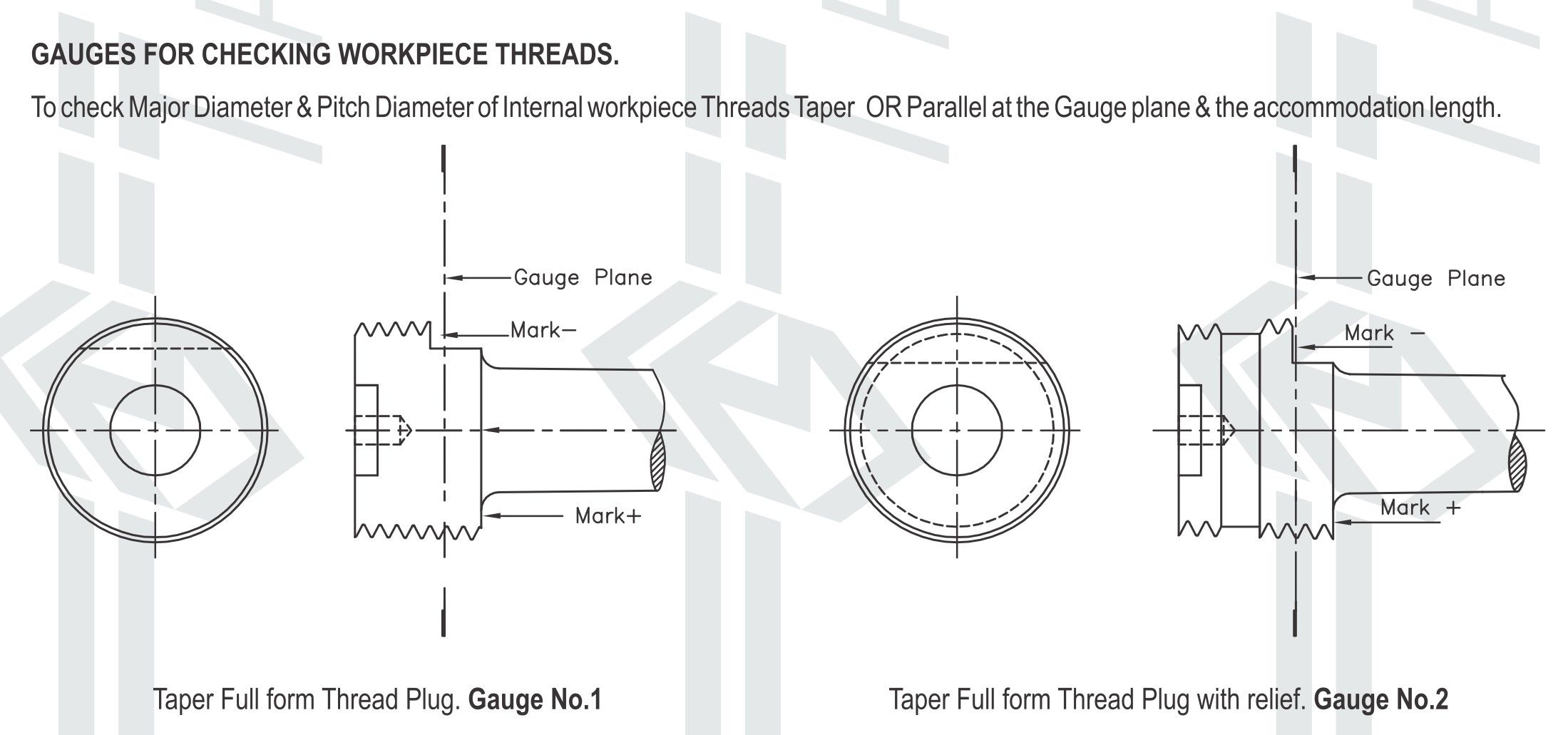

Gauges for checking workpiece threads

To check major diameter & Pitch diameter of internal workpiece Threads Taper OR Parallel at the Gauge plane & the accommodation length

The use of gauge 2, may be omitted when the design of the workpiece ensures availability of adequate accommodation length, but it should be noted that malformed threads may not be detected if Gauge No 2 is not used.

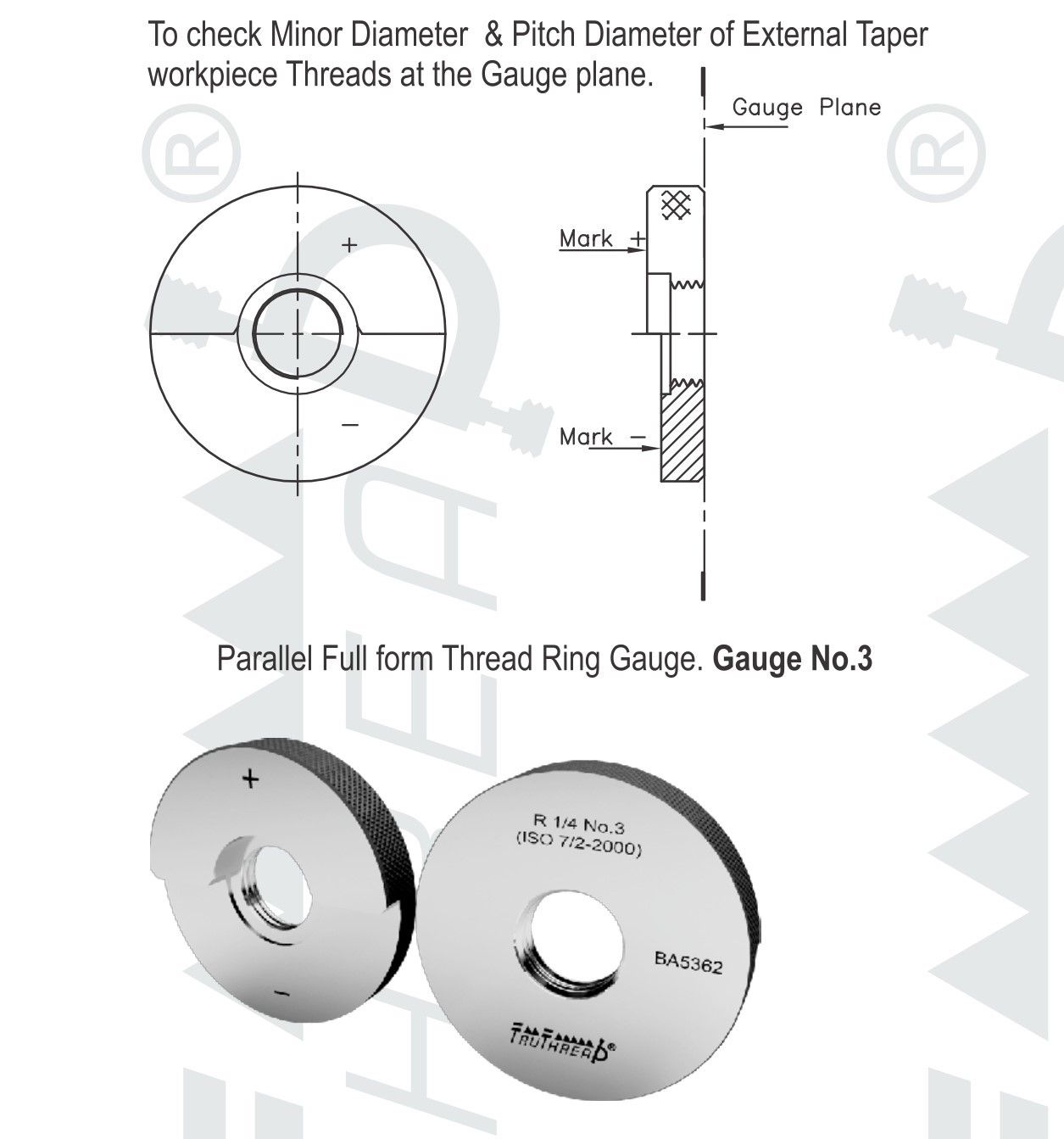

To check Minor Diameter & Pitch Diameter of External Taper workpiece threads are the gauge plane

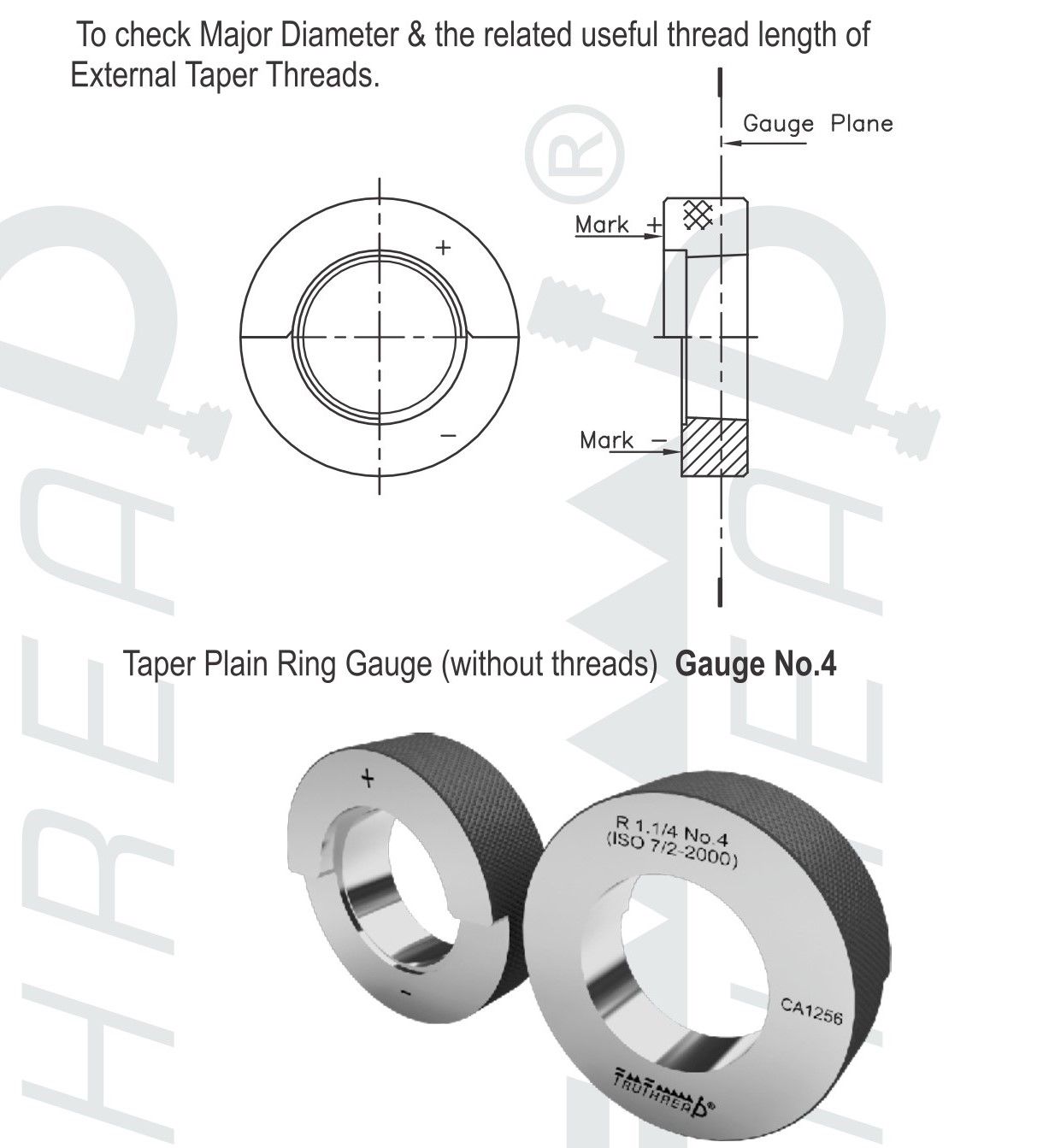

To check Major Diameter & the related useful thread length of External Taper Threads

Master gauges to check gauges (Calibration & Control purpose)

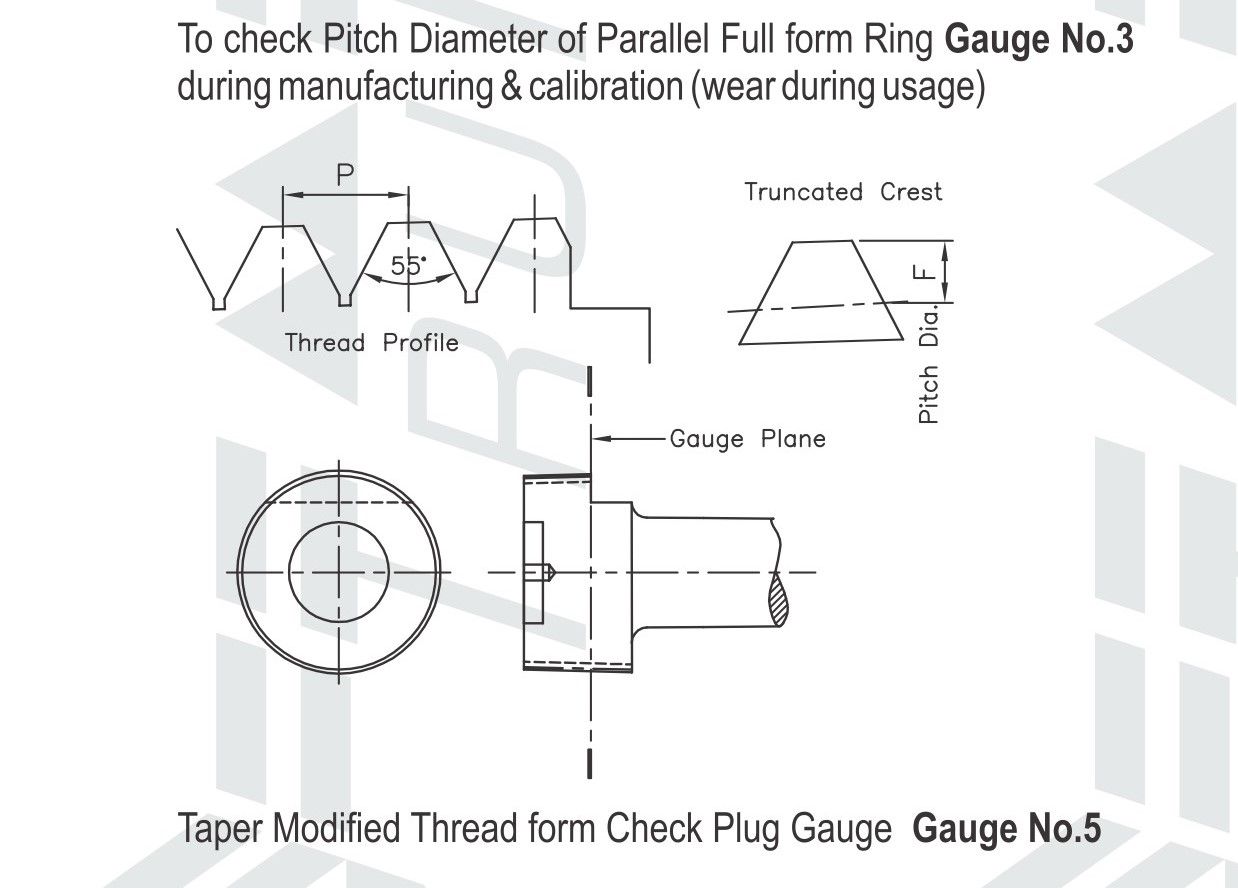

To check Pitch Diameter of Parallel Ful form Ring Gauge No 3 during manufacturing & calibration (wear during usage)

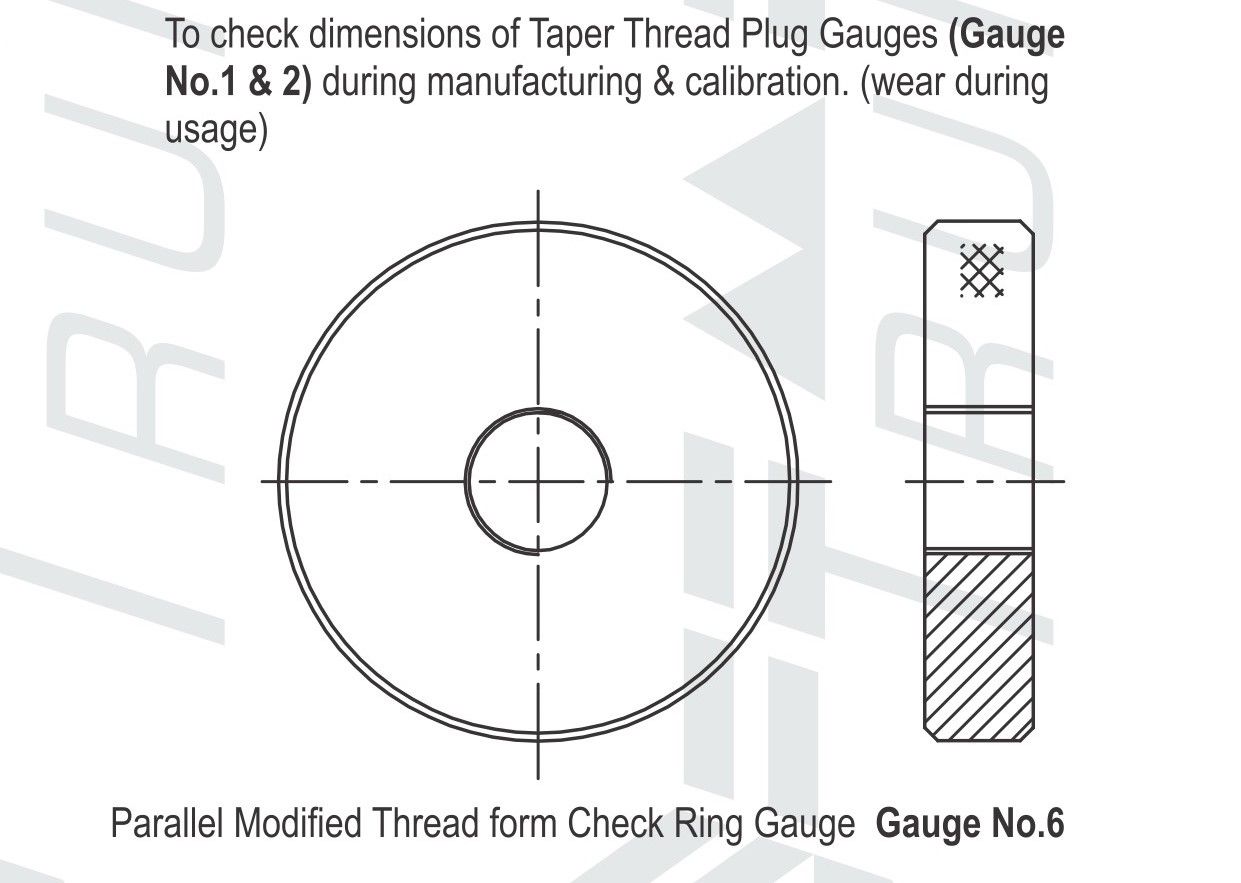

To check dimensions of Taper Thread Plug Gauges (Gauge No 1-2) during manufacturing & calibration (wear during usage)

PT Gauges - The PT Taper Plug & Taper Ring gauges specified in Appendix of JIS B 0253-1985, covers pipe sizes from ⅛ to 12’’.

Dimensions of PT Taper Thread Gauges are different than R/Rc gauges We manufacture PT gauges as per JIS B 0253-1985 standard.

Read More: What is The Difference Between R-Pipe Gauge Numbers

R-Pipe Gauge Catalog: Pipe Ring Gauges and Pipe Plug Gauges

Common requirements for pipe connections include sealing, reliability, and resistance to external influences. R-Pipe gauges (R-Rc-Rp) play a vital role in ensuring these properties. They allow for precise control of thread dimensions and geometry, ensuring proper connections and preventing leakage of fluids or gases.

The working principle of R-Pipe gauges (R-Rc-Rp) lies in their measurement and verification of thread parameters on pipes. This involves checking the thread angle, depth, width, and other characteristics that impact the quality and sealing of connections.

The application of R-Pipe gauges holds significant importance across various industries where reliable and leak-proof pipe connections are crucial. This encompasses sectors such as industrial, construction, mining, and many others.

The R-Pipe Pipe Gauge Catalog (R, Rc, Rp) from TruThread Europe presents a wide range of models for different sizes and thread types. Each gauge is accompanied by a detailed description, including technical specifications and drawings. This allows users to easily select the appropriate gauge for their needs.

What is the Difference Between R, RC, RP Gauges: A Comprehensive Guide to Threading Systems