Snap Gauges for checking the outer diameter

Snap Gauges are important tools in the world of precision measurement. They are used to determine the outer diameter of parts or workpieces with high accuracy and speed. These gauges can be particularly useful in manufacturing where it is necessary to verify that manufactured parts meet specified specifications and quality.

Snap Gauges are extremely versatile and useful tools for accurate measurements in various industries and manufacturing. They consist of two smoothly moving clamps, which are usually located at each end of the tool. These clamps can be easily inserted around the part to be measured. Thanks to their mobility and adjustment, it is possible to accurately measure the outer diameter of the part by setting the gauge clamps to a certain value that corresponds to the required size.

Technical characteristics of Snap Gauges

Manufacturing material: hardened stabilized steel AISI 01 / EN-31 (SAE 52100), Hardness 60-62 HRc.

Thanks to a special hardening process, the material becomes extremely strong and resistant to wear, which allows Snap Gauges to work under conditions of high loads and high precision. The strength of these gauges usually reaches 60-62 HRc, which is an excellent indicator of their durability and ability to withstand heavy loads without losing the quality of measurements.

This choice of material for Snap Gauges emphasizes their reliability and important role in measuring procedures where high accuracy and resistance to wear are critical factors.

Specifications: Basic dimensions: ISO 286 Part 1 & 2 - 2010, IS 919 Part 1 & 2 -1993. Gauging Practices: DIN 7163 - 1996 IS 3455 - 1971, IS 7876 - 1975.

Snap Gauges are a type of measuring tool used to check the outer diameter of parts. They exist in several varieties, depending on their purpose and measurement range:

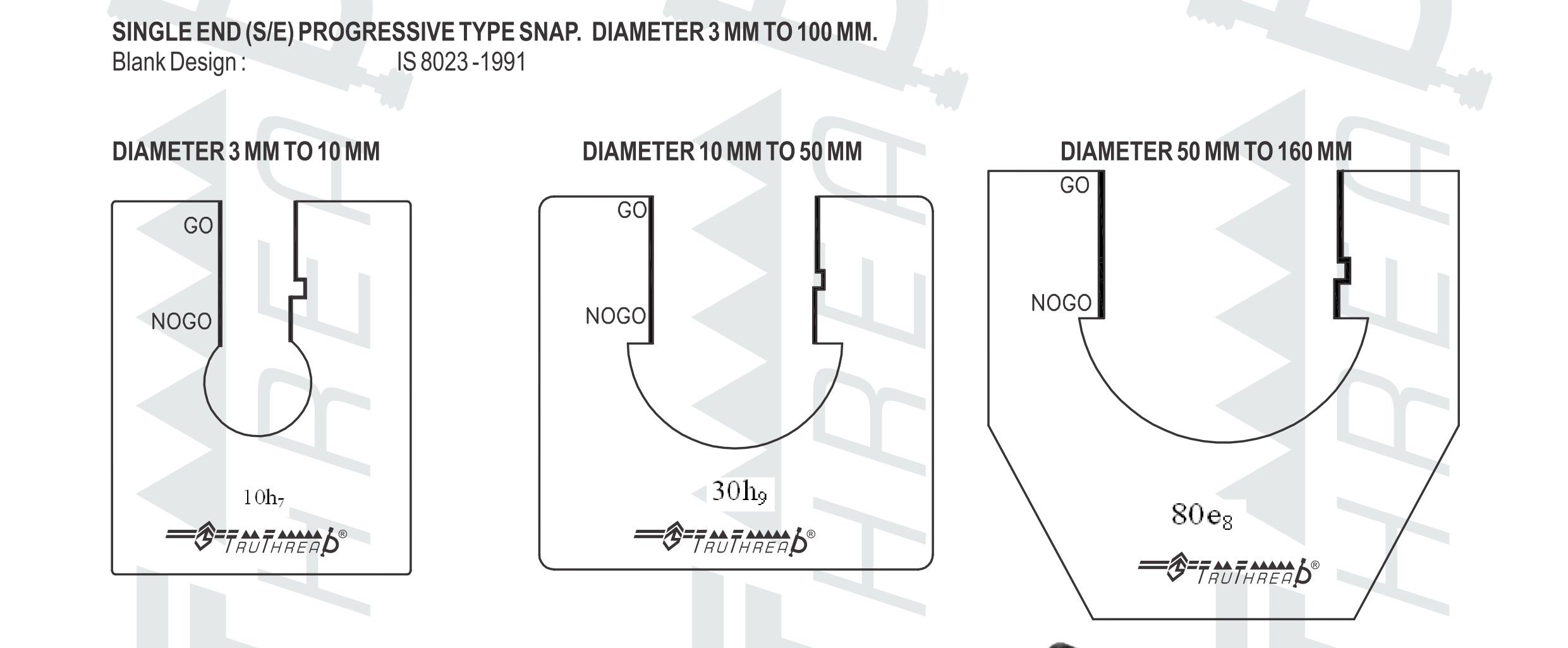

Single End (S/E) Progressive Type Snap:

Diameter: From 3 mm to 100 mm

Blank Design: Conforms to IS 8023 - 1991

Application: This type of snap gauge is designed to measure the outer diameter of parts in the specified range. They are used to ensure accuracy and compliance of parts to established standards.

Diameter: From 3 mm to 100 mm

Blank Design: Conforms to IS 8023 - 1991

Application: This type of snap gauge is designed to measure the outer diameter of parts in the specified range. They are used to ensure accuracy and compliance of parts to established standards.

Double End Snap Gauge:

Diameter: From 3 mm to 100 mm

Application: This type of snap gauge is also used to measure the outside diameter of parts within the specified range. They provide the convenience of measuring from both sides of the part, which is important in manufacturing and measuring procedures.

Diameter: From 3 mm to 100 mm

Application: This type of snap gauge is also used to measure the outside diameter of parts within the specified range. They provide the convenience of measuring from both sides of the part, which is important in manufacturing and measuring procedures.

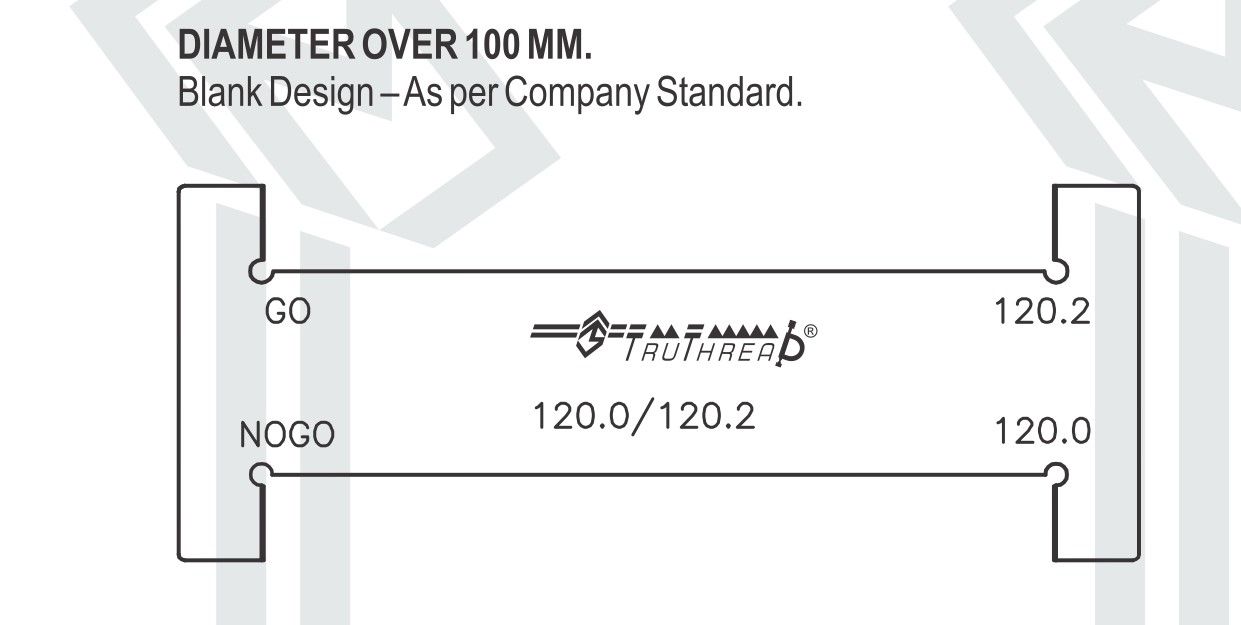

“I” Tupe Double Enf Snap:

Diameter: More than 100 mm

Blank-Design: The company's standard

Application: This type of snap gauge is used to measure the outside diameter of parts that have a larger diameter than those covered by other types of clamp gauges. They also guarantee accuracy and compliance with standards.

Diameter: More than 100 mm

Blank-Design: The company's standard

Application: This type of snap gauge is used to measure the outside diameter of parts that have a larger diameter than those covered by other types of clamp gauges. They also guarantee accuracy and compliance with standards.

These types of Snap Gauges play an important role in measuring procedures and product quality control, helping to ensure that parts are correct and conform to established specifications and standards.

Peculiarities of using Snap Gauges in measurement

These tools help ensure high accuracy and reliability of measurements, which is critical in manufacturing. Snap Gauges can be used to measure diameters from micrometric sizes to larger parts. They are used in a variety of industries, including mechanical engineering, aviation, metallurgy, automotive, and many others.

With snap gauges, it is possible to perform measurements quickly and efficiently, which helps to maintain high production quality and reduce waste. As such, these instruments are an integral part of the quality control and precision measurement process in industry.

Outside diameter measurement: The main function of Snap Gauges is to measure the outside diameter of cylindrical parts or workpieces. They allow you to accurately determine the size and diameter of the part, ensuring high accuracy of measurements.

Adjustability: Snap Gauges usually have adjustable clamps, allowing them to be adjusted for different part sizes. This will make the tools versatile and convenient to use.

Quality Control Tool: Gauges are used as quality control tools in production. They help determine whether the manufactured parts meet the given standards and specifications.

High accuracy: Snap Gauges are characterized by high measurement accuracy, which makes them indispensable for tasks where it is necessary to achieve great accuracy Variety of Applications: They are used in a variety of industries including metalworking, mechanical engineering, automotive, aerospace, medical instrumentation and many others.

Convenience and speed: Measuring with Snap Gauges is a quick and convenient process that saves time and increases productivity.

In general, Snap Gauges are indispensable for precision measurement and quality control in production and play a key role in many industries.