Unified gauges from the manufacturer TruThread Europe - UNC, UNF, UNEF, UN, UNS

Unified Thread Gauges are standardized and high-precision tools that play an extremely important role in industrial production and material processing. Their main purpose is to ensure the uniformity and compliance of thread connections to standards, which ensures reliability, efficiency and safety in the assembly and disassembly of important production structures.

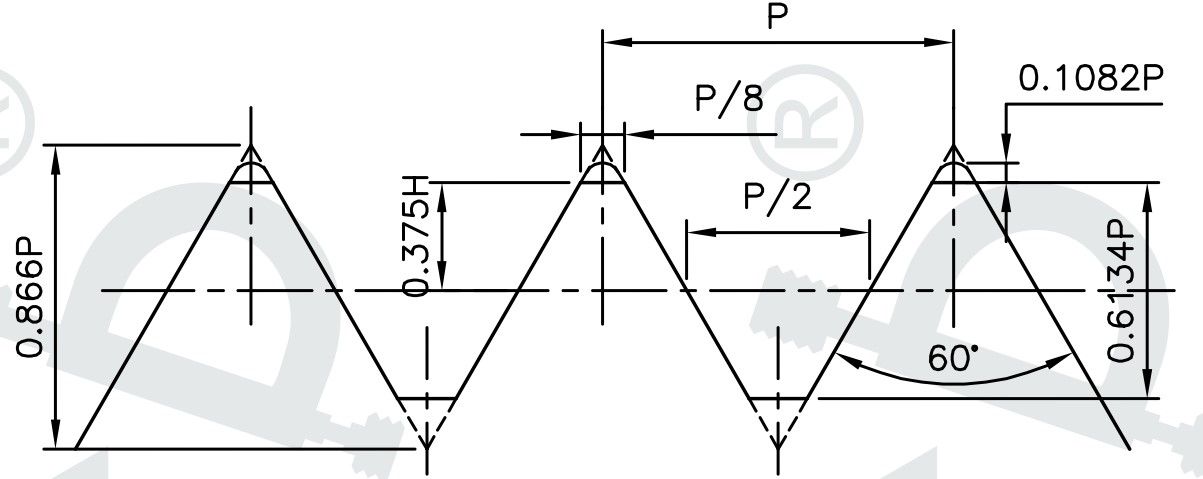

These universal tools are especially popular in the context of the Imperial System of units, which is used in many industrial sectors. With their important thread measurement function, such as diameter and Threads Per Inch (TPI), they help establish standardized parameters for thread connections. This makes them indispensable tools for ensuring high precision and reliability in the assembly and disassembly processes of components.

Moreover, unified thread gauges include various types and series such as UNC (Unified National Coarse), UNF (Unified National Fine), UNEF (Unified National Extra Fine), UN (Unified National Constant) and UNS (Unified National Special ). Each of these types of thread gauges is designed for specific use scenarios where accuracy, tightness and reliability are critical factors.

In general, Unified thread gauges not only ensure the standardization of thread connections, but also help reduce the risks of damage and loss of production productivity, making them an integral part of modern industrial processes.

Unified gauges: applications and characteristics

Application: General purpose fastening applications for Imperial system of units

Specification: ANSI/ASME B1.2-1983

We manufacture Unified Gauges with Basic Dimensions as per B.S. 1580, Part I&II-2007 & Gauging practice as per B.S. 919 Part (I)-2007 if requested by customer

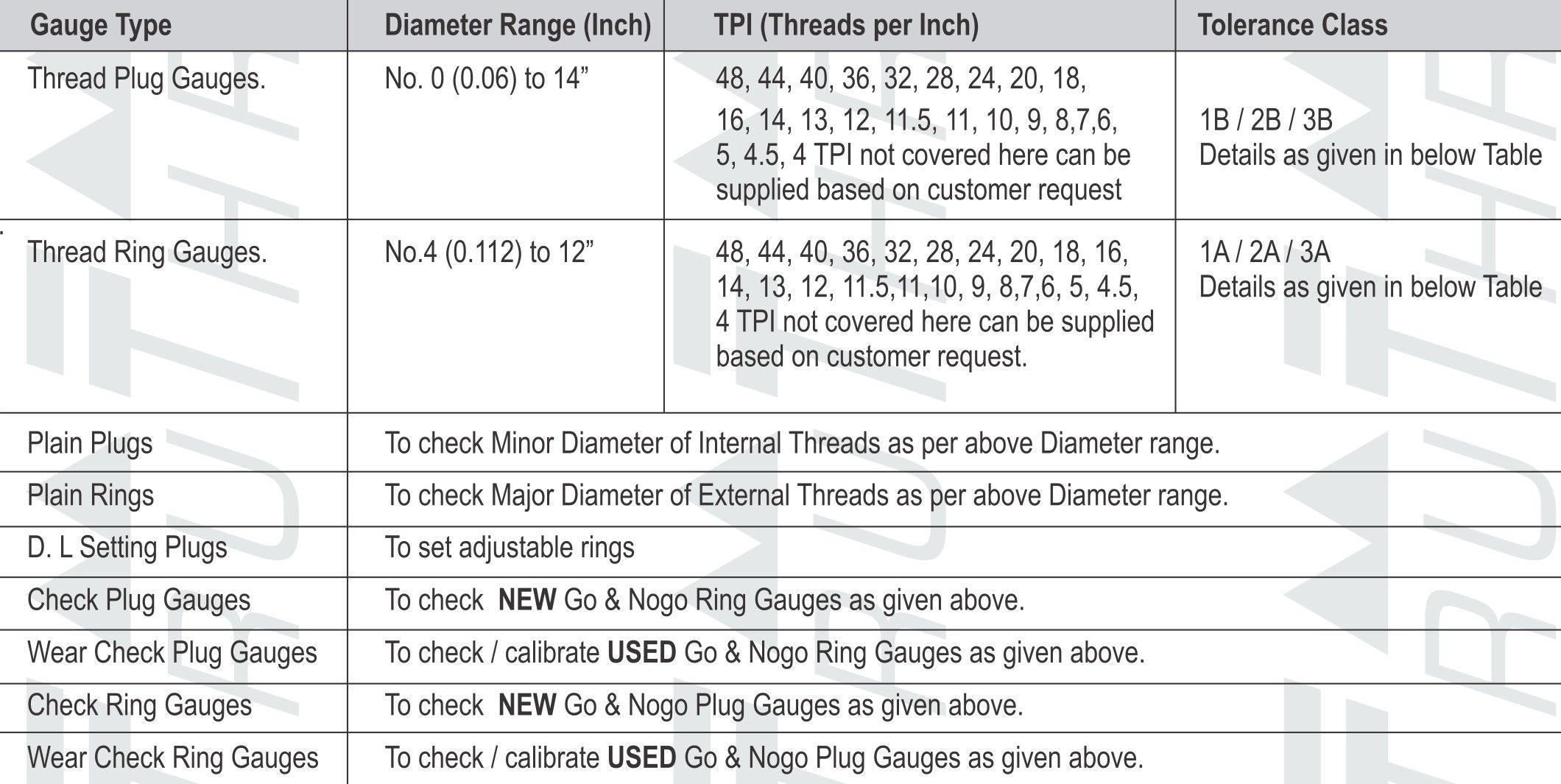

Manufacturing range

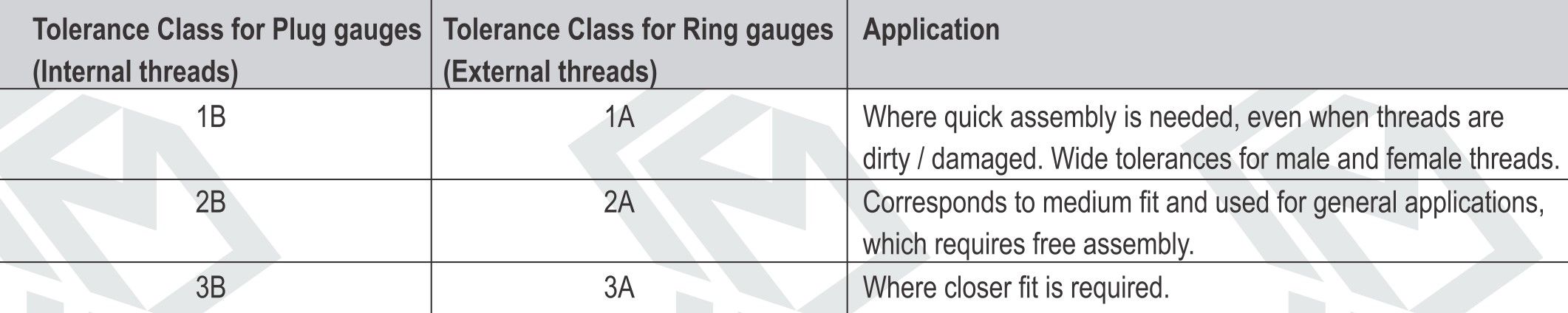

Tolerance class

In addition to above we manufacture

AG class Thread Ring Gauges for lubricant and high temperature applications as recommended in B.S. 1580, Part I&II - 2007 specification.

Class 5 Interference Fit threads as per ASME/ANSI B1.12 - 1987 specification. The recommended tolerance classes for External threads are NC-5 HF, NC-5 CSF&NC-5 ONF.

For Internal threads, the tolerance classes are NC-5 IF, NC-55 INF

We manufacture gauges to check threads of tapped holes to receive wire thread inserts / STI for Unified threads.

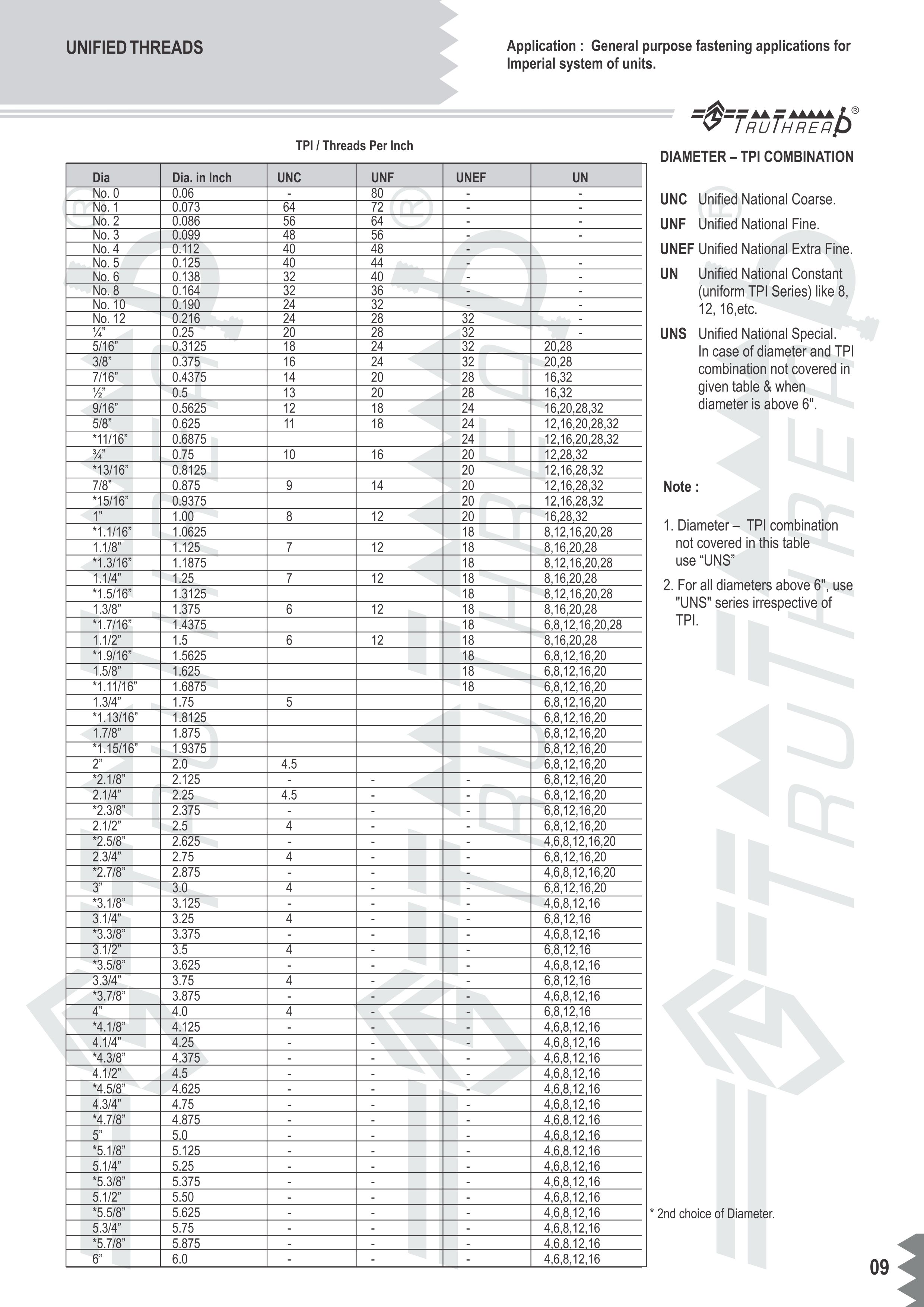

TPI Threads Per Inch

Unified gauges: UNC, UNF, UNEF, UN and UNS

Different types and series of unified thread gauges allow you to choose the best option for specific needs depending on the requirements for accuracy, strength and application features.

Note: Diameter - TPI combination not covered in this table use “UNS” For all diameters above 6”, use “UNS” series irrespective of TPI

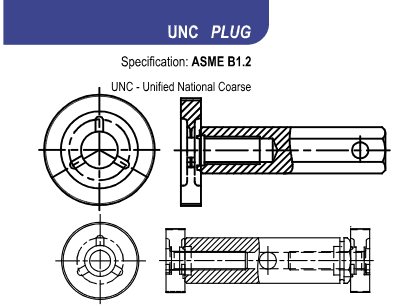

UNC thread gauges

UNC (Unified National Coarse)

This type of thread gauge is used for general industrial applications where it is important to provide a fast and strong connection. Thread parameters are less dense, which allows for faster installation of connections.

UNF Thread gauges

UNF (Unified National Fine)

UNF thread gauges have a higher TPI, which makes them suitable for parts where greater accuracy is required, but at the same time high strength of the connection is maintained.

UNEF Thread gauges

UNEF (Unified National Extra Fine)

This series of thread gauges has an even higher TPI, so it is used in demanding applications where high accuracy of thread connections is required.

UN Thread gauges

UN (Unified National Constant)

Unified threads with a constant TPI (eg 8, 12, 16, etc.) are designed for the specific requirements of applications where a constant rotational speed or relationship between parts must be maintained.

UNS Thread gauges

UNS (Unified National Special)

This series is used for special scenarios where the diameter and TPI are not covered by other series, or when the diameter exceeds 6 inches. UNS thread gauges provide flexibility in the selection of parameters for complex production tasks.

Unified thread gauges, including UNC, UNF, UNEF, UN and UNS, play an important role in ensuring the standardization and reliability of thread connections in industrial and manufacturing areas. Each type and series has its own unique specification that takes into account the requirements for strength, accuracy and specific application characteristics.

Overall, the variety of unified thread gauges allows fabricators, installers, and material handlers to choose the best option based on the specific needs and requirements of their projects. Such standardization contributes to the implementation of high standards of quality and efficiency in industrial processes, helping to ensure the stability and reliability of thread connections in various industries.