What is the Difference Between R, RC, RP Gauges: A Comprehensive Guide to Threading Systems

Understanding the distinctions between R, RC, and RP gauge systems is crucial for ensuring proper thread verification and quality control. These threading designations represent different approaches to internal and external thread configurations, each serving specific applications in industrial manufacturing. At TruThread Europe, we recognize the importance of clarity in threading standards, which is why we've compiled this comprehensive guide to help you navigate these critical distinctions.

The evolution of threading standards has led to the development of sophisticated gauge systems that accommodate both taper and parallel thread configurations. Whether you're working with pipe threads, hydraulic fittings, or precision mechanical assemblies, selecting the correct gauge type directly impacts the integrity and performance of your threaded connections.

Historical Context and Standards Evolution of R-Gauges

The BS 21-1985 Legacy

The foundation of modern taper threading systems can be traced back to the BS 21-1985 standard, which originally specified BSPTr (BSP Taper Threads). This pioneering standard established a comprehensive framework where both external and internal threads followed a taper or conical configuration. Under this system, manufacturers relied on taper thread plugs to verify taper internal threads, while taper thread rings served to check taper external threads.

The BS 21-1985 standard introduced two distinct gauge systems: System A and System B. These systems provided manufacturers with flexibility in gauge selection while maintaining consistent verification standards across different applications. However, as industrial requirements evolved and international standardization became increasingly important, the need for updated specifications became apparent.

Transition to Modern Standards

The threading industry experienced a significant transformation when BS 21-1985 was replaced by ISO 7/2-2000. This transition represented more than just a nomenclature change; it marked a fundamental shift toward international harmonization of threading standards. The British Standards organization subsequently adopted this ISO standard, publishing it as BS EN 10226-3-2005.

This evolution from BS 21-1985 to BS EN 10226-3-2005 reflects the industry's commitment to global standardization while maintaining the precision and reliability that modern manufacturing demands. The obsolescence of BS 21-1985 and its replacement with BS EN 10226-3-2005 ensures that contemporary threading applications benefit from the most current technological understanding and best practices.

Understanding the R, RC, RP Classification System

External Thread Configuration: The R Designation

Under the current ISO 7/2-2000 and BS EN 10226-3-2005 standards, external threads maintain a consistently taper configuration. These threads are universally denoted by the letter "R" as the first character of their size designation. This standardization simplifies identification while ensuring consistent performance across applications. For example, an R1/2 designation indicates an external taper thread with a 1/2-inch nominal size. The taper configuration of R threads provides several advantages, including improved sealing capabilities and enhanced mechanical strength under pressure. This design particularly benefits applications involving fluid transfer, where the gradual taper creates a wedging action that enhances seal integrity as the connection tightens.

The consistent taper angle of R threads, typically 1:16 (equivalent to approximately 3.57 degrees), ensures predictable engagement characteristics across different manufacturers and applications. This standardization eliminates compatibility concerns while providing reliable performance in demanding industrial environments.

Internal Thread Variations: RC and RP Systems

Internal threads present more complexity, as they can be configured in either taper or parallel configurations depending on application requirements. This flexibility allows engineers to select the most appropriate internal thread type based on specific performance criteria, installation constraints, and operational demands.

Taper Internal Threads: The RC Designation

Internal threads configured with a taper profile are designated with "RC" as the first letters of their size identification. For instance, an RC1/4 represents a taper internal thread with a 1/4-inch nominal size. The taper configuration of RC threads provides several distinct advantages in specific applications.

RC threads create a metal-to-metal seal as the taper external thread (R) engages with the taper internal thread (RC). This configuration generates increasing contact pressure as the threads are tightened, resulting in superior sealing performance without requiring additional sealing compounds in many applications. The wedging action inherent in taper-to-taper connections makes RC threads particularly suitable for high-pressure applications where leak prevention is critical.

The manufacturing precision required for RC threads demands careful attention to taper angle consistency, thread pitch accuracy, and surface finish quality. These factors directly influence the sealing effectiveness and mechanical performance of the completed connection.

Parallel Internal Threads: The RP Designation

Parallel internal threads, designated with "RP," offer distinct advantages in applications where ease of assembly, disassembly, or adjustment is prioritized. An RP1-1/2 designation, for example, indicates a parallel internal thread with a 1-1/2 inch nominal size.

RP threads maintain a constant diameter throughout their length, creating a different engagement characteristic when mated with taper external threads (R). This configuration allows for more predictable torque requirements during assembly and often facilitates easier disassembly when maintenance or component replacement is necessary.

The parallel configuration of RP threads makes them particularly suitable for applications involving frequent assembly and disassembly cycles. Additionally, RP threads often accommodate sealing compounds or tape more effectively than their taper counterparts, as the parallel walls provide consistent clearance for sealant distribution.

Gauge Selection and Verification Methods

Verifying Internal Threads: The Universal Plug Approach

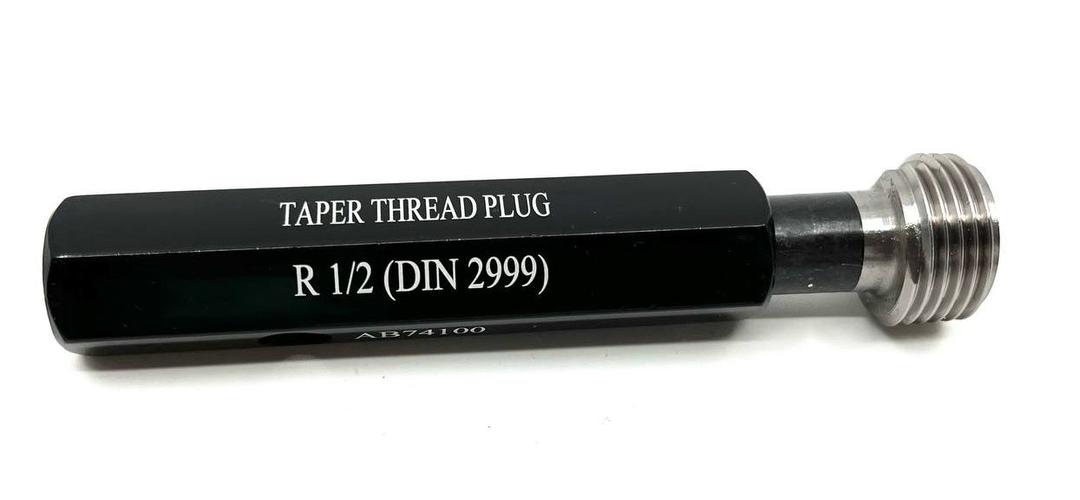

One of the most significant advantages of the current threading standard lies in its simplified verification approach for internal threads. Whether checking parallel (RP) or taper (RC) internal threads, manufacturers utilize the same Taper Thread Plug Gauge No.1. This standardization reduces inventory requirements while ensuring consistent verification standards across different thread types.

The size designation for these plug gauges incorporates both RC and RP nomenclature (RC/RP), indicating their dual capability. This unified approach streamlines quality control processes while maintaining the precision required for reliable thread verification. The taper design of Gauge No.1 provides accurate verification for both taper and parallel internal threads through different engagement criteria.

For taper internal threads (RC), the plug gauge engagement depth indicates thread accuracy, with proper threads allowing the gauge to advance to the specified position. For parallel internal threads (RP), the gauge verification focuses on the thread's ability to accommodate the taper plug within specified tolerance limits, ensuring proper clearance for external thread engagement.

Plug Gauge No.2 (Taper Full Form Thread Plug Gauge with Relief) is used in cases where a smoother and safer inspection of internal threads is required. Unlike Gauge No.1, No.2 features a special “relief” – a small section where the thread is not fully formed, allowing the gauge to enter the thread easily without the risk of deformation. This is particularly critical when inspecting large internal threads or threads in high-density materials, where using Gauge No.1 could cause jamming or thread damage.

Gauge No.2 is effective for checking the major diameter of internal threads, as well as in situations where additional clearance is needed to ensure proper gauge engagement. Its design allows for precise control and verification of thread compliance with standards while minimizing mechanical impact on the part.

As a result, Gauge No.2 becomes an essential tool for sensitive or critical assemblies, where even minor thread deformation could affect sealing or load-bearing connections. Manufacturers often use it after Gauge No.1 to confirm thread accuracy and provide an extra layer of quality assurance.

External Thread Verification: The Combination Approach

External taper threads (R) require a more sophisticated verification approach utilizing a combination of two distinct gauges. This dual-gauge system ensures comprehensive verification of both thread form accuracy and dimensional compliance.

Full Form Thread Ring (Gauge No.3)

The Full Form Thread Ring, designated as Gauge No.3, verifies the complete thread profile of external taper threads. This gauge checks thread pitch accuracy, flank angles, and overall thread form compliance. The full engagement of Gauge No.3 confirms that the external thread meets all geometric requirements specified in the standard. The design of Gauge No.3 incorporates the precise thread form and taper angle required for accurate verification. Manufacturing tolerances for these gauges are extremely tight, ensuring that parts verified as acceptable will perform reliably in service applications.

Taper Plain Ring (Gauge No.4)

The Taper Plain Ring, known as Gauge No.4, focuses on dimensional accuracy and taper angle verification. This gauge lacks thread form details, instead presenting a smooth taper bore that matches the thread's major diameter envelope. Gauge No.4 verification ensures that the external thread's dimensional characteristics will provide proper engagement with internal threads.

The combination of Gauge No.3 and Gauge No.4 provides comprehensive verification that addresses both geometric accuracy and dimensional compliance. This dual-gauge approach ensures that external threads will perform reliably across their intended applications while maintaining the precision required for critical sealing and mechanical performance.

Practical Applications and Selection Criteria of R-Pipe gauges

Application-Specific Considerations

Selecting between RC and RP internal thread configurations depends on several critical factors that directly impact system performance and reliability. Understanding these considerations enables engineers to make informed decisions that optimize both immediate functionality and long-term service life.

High-pressure fluid systems typically benefit from RC (taper internal) configurations due to their superior sealing characteristics. The metal-to-metal contact created by taper-to-taper engagement provides reliable leak prevention without additional sealing materials. Conversely, applications requiring frequent maintenance access often favor RP (parallel internal) configurations for their ease of assembly and disassembly. Temperature cycling applications present unique challenges that influence thread selection. Taper configurations (RC) may provide more consistent sealing under thermal expansion and contraction, while parallel configurations (RP) might accommodate thermal movement more readily in certain applications.

Manufacturing and Quality Control Implications

The choice between RC and RP configurations also impacts manufacturing processes and quality control requirements. Taper internal threads (RC) demand precise angle control and consistent taper rates throughout the threading process. Parallel internal threads (RP) require excellent cylindricity and pitch accuracy but avoid the complexity of taper angle maintenance.

Quality control procedures must account for these differences, with appropriate gauge selection and verification techniques tailored to each thread type. The standardized gauge system simplifies inventory management while ensuring that verification standards remain consistent across different thread configurations.

The distinction between R, RC, and RP gauge systems represents a sophisticated approach to threading standardization that accommodates diverse industrial requirements while maintaining precision and reliability. External threads consistently utilize the R (taper) configuration, providing standardization benefits and reliable performance characteristics. Internal threads offer flexibility through both RC (taper) and RP (parallel) options, allowing engineers to select the configuration that best meets their specific application requirements.

The evolution from BS 21-1985 to ISO 7/2-2000 and BS EN 10226-3-2005 demonstrates the industry's commitment to continuous improvement and international standardization. This progression has resulted in clearer nomenclature, simplified verification procedures, and enhanced compatibility across global manufacturing operations.

At TruThread Europe, we understand that proper gauge selection and verification are fundamental to achieving reliable threaded connections. Whether your application demands the superior sealing of RC configurations, the assembly convenience of RP systems, or the standardized performance of R external threads, selecting the appropriate gauge system ensures optimal results.

The unified verification approach for internal threads through Taper Thread Plug Gauge No.1, combined with the comprehensive dual-gauge system for external threads, provides manufacturers with the tools necessary to maintain consistent quality standards. This systematic approach to thread verification supports both current production requirements and future standardization initiatives.

Understanding these distinctions empowers manufacturers to make informed decisions about thread selection, gauge procurement, and quality control procedures. As threading technology continues to evolve, the fundamental principles underlying R, RC, and RP systems will remain central to achieving reliable, precision-threaded connections across diverse industrial applications.