G-Pipe thread gauges: Technical Characteristics and Applications

G-Pipe thread gauges are specialized tools designed to measure and check the dimensions of thread connections on pipelines. These gauges provide high accuracy and reliability in determining the parameters of thread connections, which is an important factor in the construction and operation of pipe systems.

In various industries where piping systems play a critical role, such as industry, oil and gas, construction and transportation, the importance of accurate dimensioning of thread connections cannot be overstated. G-Pipe thread gauges allow you to ensure compliance of thread sizes with regulatory requirements and standards, thereby ensuring safe and efficient operation of pipelines.

In addition, G-Pipe thread gauges can be used in situations where tightness is not required at thread connections. This makes them particularly useful for applications where dimensional accuracy verification is key and tightness does not affect system functionality.

G-Pipe thread gauges: tolerances and characteristics

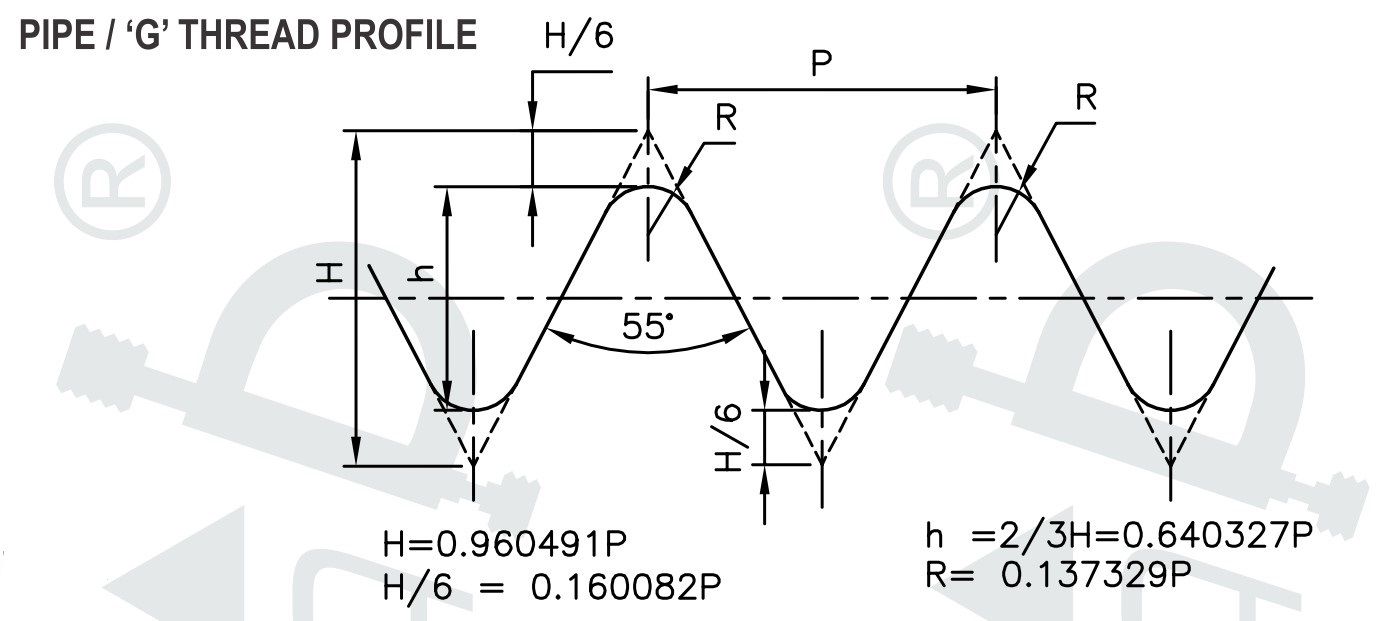

Specification: I.S.O. standard - Basic Dimensions: ISO 228 (1) - 200 (E) Gauging Practice: ISO 228 (2) - 1987 (E)

Indian Standard - Basic Dimensions: IS 2643 - 2005 Gauging Practice: IS 10216 - 1988

BSI Standard - B.S 2779 - 1986 JIS standard - B 0202-1999

JIS B 0202-1999 Specification covers sizes from ⅛” to 6”, are based on ISO specification. The sizes above 6” Pipe Diameter are manufactured on JIS. The designation used for Parallel Pipe threads in JIS is PF.

Manufacturing range

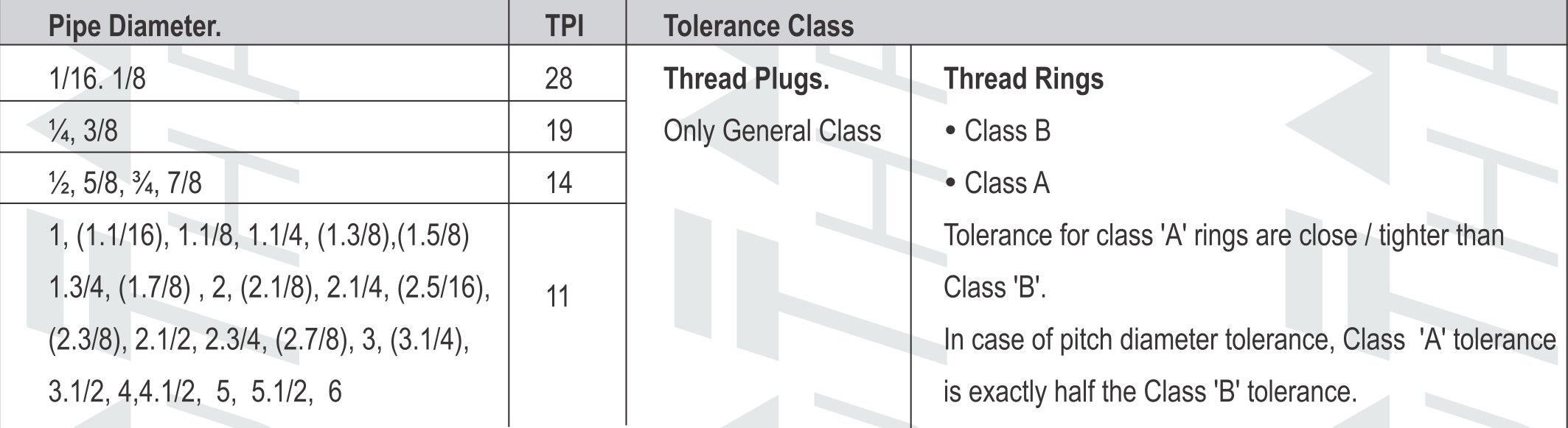

Pipe diameters in parenthesis () are not recommended in above refereed IS/ISO specifications. On customer request we can manufacture gauges for these sizes

G-Pipe thread plug gauges

G-Pipe thread gauges are designed for accurate measurement and inspection of thread connections on pipelines. These gauges are made of high-quality steel, which ensures their durability and reliability. They are an integral part of the manufacture and installation of pipe systems in various industries, including industry, construction and transport.

G-Pipe thread plug gauges are available in various sizes and general accuracy classes. Tube diameters vary from 1/16 to 6 inches. The presence of different classes of sizes allows you to choose the necessary tool depending on the specific task. See the table above for more on available sizes and thread pitch.

G-Pipe thread gauges meet the general accuracy class, making them versatile tools for many different applications. High quality and precision contribute to the creation of reliable and efficient pipe connections in various dimensions and areas of application.

G-Pipe thread ring gauges

G-Pipe thread ring gauges are used for accurate measurement and inspection of thread connections on pipelines. These gauges are designed to ensure the reliability and accuracy of thread connections, which is critical for the safe and efficient operation of piping systems in various industries.

You can learn more about the dimensions of G-Pipe thread gauges from the table above. The TruThread manufacturer's assortment includes G-Pipe rings from 1/16 to 6 inches.

In addition, G-Pipe thread ring gauges are classified by accuracy classes: Class A and Class B. The tolerance for Class A rings is closer / tighter than for Class B rings. In the case of the pitch diameter tolerance, the Class A tolerance is exactly half of the Class tolerance B. This variety of grades and sizes makes G-Pipe thread ring gauges indispensable tools for ensuring the quality and reliability of threaded connections on pipelines.

Read more about The Differences Between Class A and Class B Tolerances for G-Pipe Ring Gauges